Phone: 317-337-9813 www.continentalchillers.com

Fax: 317-337-9816

Continental Single Phase Chillers

UniPac™

UniPac™ Options and Selection Procedures

1. Control Transformer - For applications where a separate 115-volt power

source is not available, a transformer can be installed and wired between the line

voltage power terminal block and the 115-volt control circuit. Transformer primary

fuses are included.

2. Factory mounted and wired flow switch - This accessory is mandatory for

Continental warranty to be effective. Provides protection from chiller freezing due to

“no flow” through chiller-evaporator.

3. Factory Mounted and Wired Chiller Water Pump/Valve - Includes chilled

water circulating pump, pump starter, and isolation valve. Provides system pump for

chilled water circulation- saves field labor and material. This pump is interlocked with

the flow switch and “phased in” at the factory for proper rotation.

4. Non-fused Disconnect - Factory mounted non-fused disconnect sized for

model and voltage. This saves field labor and material.

5. Low Evaporator Pressure Freezestat - Senses low evaporator pressure and

shuts down system after sixty second time delay. Extra safety protection against low

pressure due to gas shortage or freeze conditions.

6. Pressure Gauges - Two-inch diameter gauges are factory installed and piped

to compressor. High and low pressure for each refrigerant circuit.

7. Indicator Lights - Three indicating lights show Power On, High Pressure Fail,

and No Flow/Freeze for each refrigerant circuit.

8. Vibration Isolators - Level adjusting spring type for one-inch deflection for

field mounting-reduces vibration transmission.

9. Low Ambient Controls - Standard units have fan cycling and are good for

45°F ambient.

a) For Low Ambient of 0°F. Includes a modulating solid state fan speed controller

and a single phase condenser motor(s) as well as fan cycling.

b) For Low Ambient of –20°F. Includes head pressure control valve in conjunction

with oversized heated and insulated receiver(s) and fan cycling. Receiver includes

pressure relief valve.

10. Micro-Processor Controller

11. Water Regulating Valve - Provides head pressure control for water cooled

models USWC.

12. 90/10 Cu-Ni Condenser - For water cooled models, USWC.

13. Blygold or Heresite Coated Condenser - Coil is coated with Blygold or

Heresite for protection against elements. Minimal effect on heat transfer.

14. Copper Tube/Copper Fin Condenser Coil - Seamless copper tube with die

formed copper fins, mechanically bonded to the tube. Provides maximum protection

from salt-water environment due to the elimination of dissimilar metals.

15. Complete Unit Coating - Your choice of paint, Blygold, Imron, polyester or

Heresite coating for compete unit.

16. Stainless Steel Hardware - For extra protection against corrosion.

17. Low Speed Condenser Fan Motors - For lower noise levels

18. Centrifugal Condenser Fans - For ducted applications

19. Acoustical Enclosure - Compressor is located in an acoustical enclosure

providing dampening of sound levels.

20. Dual Unit Kit - Allows operation of two or more units

21. Alarm Bell Contacts - Allows alarm bell connection to pressure controls for

signaling if unit fails on manual reset safety controls. (alarm bell is not included but

can be provided)

22. Water Flange Kit - Factory or field mounted consists of 150lb raised face

flanges to convert male pipe thread to flanged cooler connections.

23. High Return Water Thermostat - Factory mounted thermostat senses high

return water temperature at start-up. Allows unit to run un-loaded instead of shutting

down due to high head pressure

24. Brine Chilling - Modified cooler and controls for various

brines/glycols/alcohols.

25. High entering Water Process Cooling - Secondary plate heat exchanger

with pump, factory mounted and wired to protect compressor against burnouts due to

high water temperatures.

26. Potable/Ingredient Water at 34°F - For bakeries/produce or other

applications.

27. Cooler Heater with Thermostat - For freeze protection.

28. Desuperheaters - Provides “free hot water” by recovering heat from super

heated gas.

29. Compressor Circuit Breaker - Both fused and non-fused short circuit

protection for each compressor, further reducing chance of motor burnout.

30. Digital Temperature Readout

31. Compressor Cycle Counter/Hour Meters

32. Non-Ozone Depleting, Environmentally-Friendly Refrigerant

Ratings and Selection Procedures

1. Ratings: are in accordance with ARI standard for chillers. These ratings

may be interpolated for any published chilled water temperatures between 40°F

and 50°F but must not be extrapolated.

2. Chilled Water Flow: based on 2.4 GPM per Ton and 10°F chilled water

range. Limit 6°F minimum to 14°F maximum.

3. Cooler Fouling Factor: 0.00025 fouling is standard

For 0.0005 fouling capacity correction factor = 0.982 x TR, 0.994 x kW

For 0.00075 fouling capacity correction factor = 0.964 x TR, 0.989 x kW

4. Water cooled condenser fouling factor : ratings are based on 0.00025 for

condenser. For 0.00075 Condenser tons x 0.97 –kW x 1.045

5. Copper Fin Ratings: TR x 1.01 – kW x 0.99

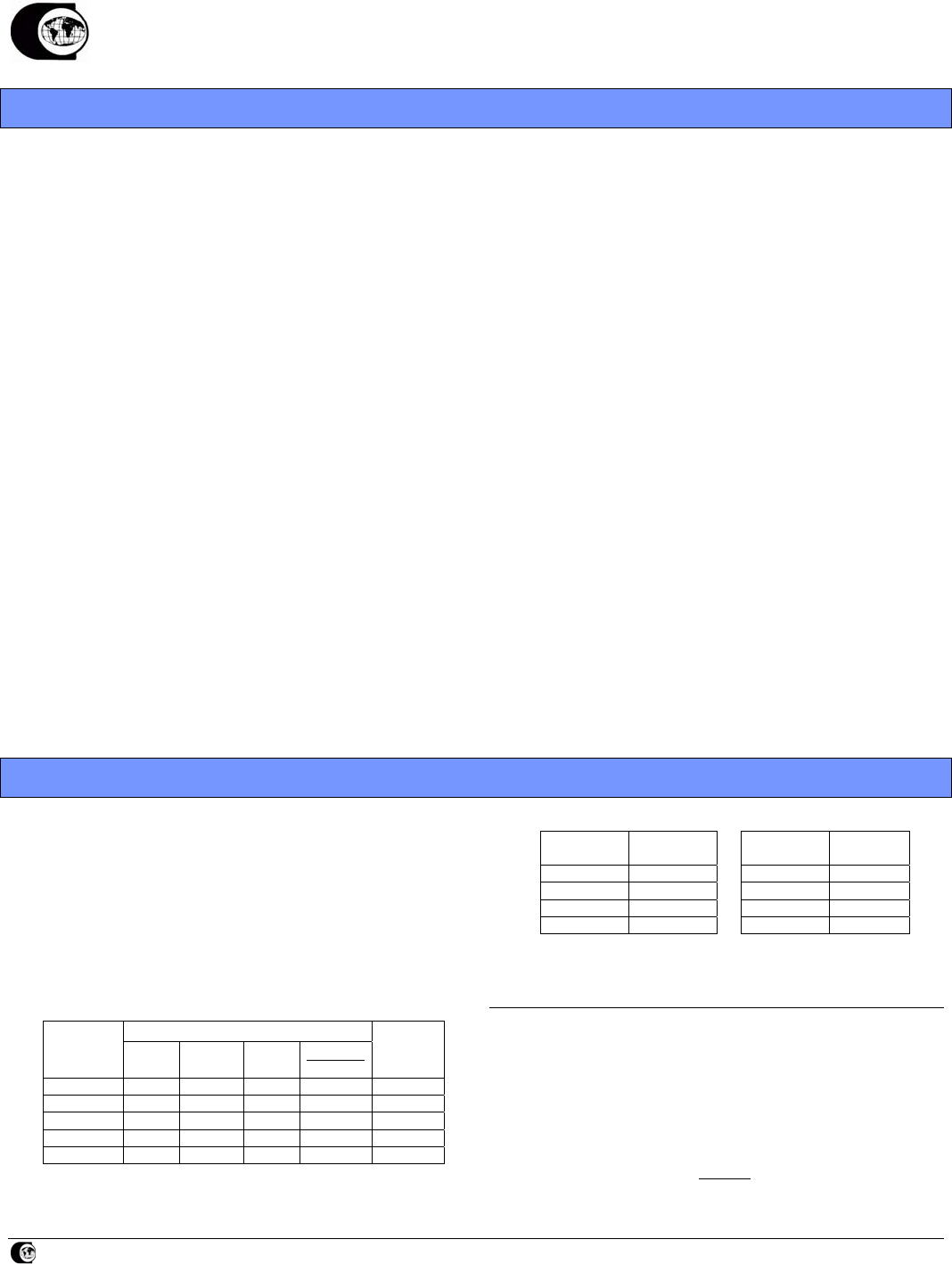

6. Ethylene Glycol Correction Factors: Following factors are to be applied

to the standard ratings for ethylene glycol. For other glycols consult factory.

Correction Factors

% Wt.

Ethylene

Glycol

Tons

kW

VP

GPM/

°F /Ton

Freeze

Point

(°F)

10 .995 1.000 1.02 24.1 26

20 .990 0.995 1.05 24.8 16

30 .980 .990 1.10 26.0 5

40 .975 0.985 1.13 27.3 -10

50 .960 0.980 1.18 29.0 -32

Altitude: Ratings are based on altitude of sea level. For other ratings use the following

correction factors

Alt. Above

Sea Level

Capacity

Multiplier

Alt. Above

Sea Level

Capacity

Multiplier

Sea Level 1.0 4000 .971

1000 1.0 5000 .962

2000 .995 6000 .951

3000 .980 7000 .949

7. For ratings outside this catalog range consult Continental for assistance

Tel:(317)337-9813 Fax:(317)337-9816 E-mail: sales@continentalchillers.com

Selection Procedures

All units are rated in accordance with ARI Standard and cover a wide range of leaving

chilled water temperatures and ambients from 85°F to 120°F.

To select any chiller it is necessary to know:

1. Capacity: ______ Tons

2. Entering and leaving chilled water temperature: ______ °F

3. Water Flow: ______ GPM

4. Design ambient temperature: ______ °F or

5. Entering/leaving cond. water temperature, for water cooled units: ______ °F

Knowing any two of items 1,2 or 3, the third can be calculated as follows:

GPM = Tons x 24

Temp. Rise(Vt)

4