Safe Chill™ Blast Chillers Service & Installation Manual

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

6

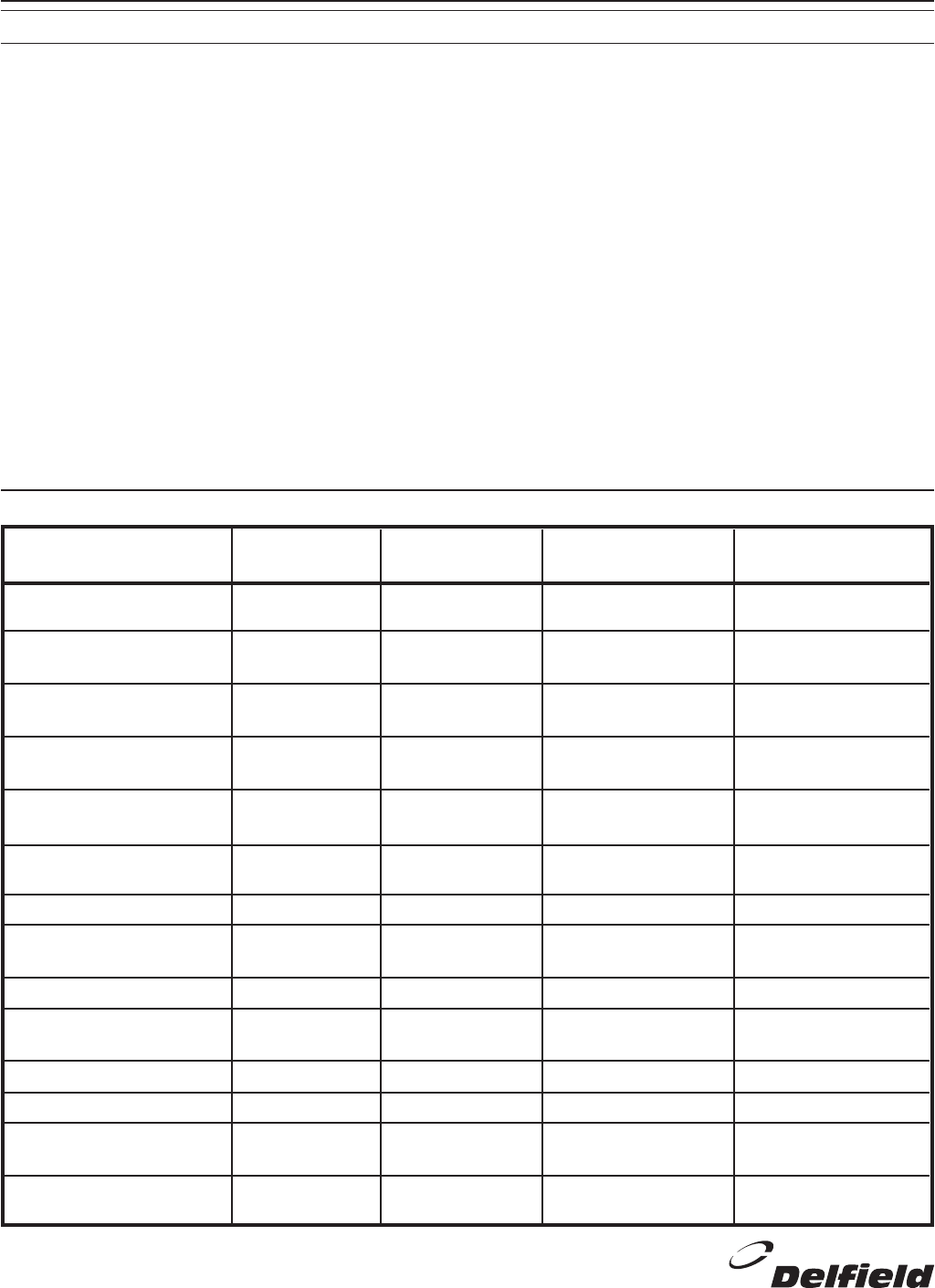

PARAMETER

DESCRIPTION PARAMETER DEFAULT RANGE COMMENTS

Food probe

temperature (chilling) (FP1) 37˚F 28˚F to 40˚F

Food probe

temperature (hard chilling) (FP2) 47˚F 0˚F to 70˚F

Food probe

temperature (freezing) (FP3) 0˚F -20˚F to 10˚F

Box temperature

(soft/hard chilling) (BT1) 23˚F 20˚F to 37˚F

Box temperature

(hard chilling) (BT2) -5˚F 20˚F to 37˚F

Box temperature

(freezing hold) (BT3) -15˚F -5˚F to -30˚F

Maximum chill time (TC1) 240 minutes 0 to 240 minutes

Defrost termination

(temperature) (DF1) 55˚F 40˚F to 70˚F

Defrost termination (time) (DF2) 15 minutes 0 to 90 minutes

Defrost cycle time

(freezing) (DF3) 360 minutes 180 to 480 minutes

Print output (PR1) (PR1) OFF to PR1

Print interval (PT1) 5 minutes 0 to 480 minutes

Maximum coil temperature

(evaporator fan) (MCT) 30˚F 20˚F TO 60˚F

Chill time recall (CTR) Recall 0 to chill time alarm Stores last chill

(TC1) time /or preset

List of Parameters

MAINTENANCE

The interior and exterior can be cleaned using soap and warm

water. If this isn’t sufcient, try ammonia and water or a

nonabrasive liquid cleaner. When cleaning the exterior, always

rub with the “grain” of the metal to avoid marring the nish. Do

not use an abrasive cleaner because it will scratch the metal.

In order to maintain proper refrigeration performance, the con-

denser ns must be cleaned of dust, dirt and grease regularly.

The condenser coil is located behind the removable louvered

front and there are two coils located on the DBC-10. It is

recommended that these be cleaned at least once every three

months. If conditions are such that the condenser is totally

blocked in three months, the frequency of cleaning should

be increased. Clean the condenser with a vacuum cleaner

or stiff brush. If it’s extremely dirty, a commercially available

condenser cleaner may be required.

Door gaskets are dart style and can easily be replaced without

the use of any tools. Do not use sharp tools or knives to

scrape the bellows as this may tear the gasket and eliminate

its ability to seal. Door gaskets should be cleaned as required

to maintain their ability to seal properly. A soft bristle brush

and solution of soap and water will keep the gaskets clean. Do

not use full strength de-greasing agents on the gasket.

Pan slides are removable via the four thumb screws and are

made of stainless steel. They are dishwasher safe or can be

cleaned with soap and water.

Food Probes:

If necessary to check the probes, they are a 10,000 ohm

thermistor and it is important that they be kept away from

any high voltage wiring. There are four probes per section;

two food probes, one box probe and an evaporator probe.

Accessing the evaporator, expansion valve, and other evapora-

tor components can be done by removing the pan slides and

pulling the evaporator housing away slowly as to not pull out

any wiring. Once access has been gained wire ties can be

cut and the housing can be removed. Food probes can be

cleaned with soap and water. For optimum use of the food

probes, do not allow the handle to rest in the food. When

removing a food probe from the food do not pull on the cable,

use the handle.

The control uses a lithium battery and may need to be

replaced approximately every ve years.