20

ባ

OPERATIONS TO BE PER-

FORMED WHEN SUBSTI-

TUTING THE INJECTORS

✓ Remove the gratings and the burner

covers;

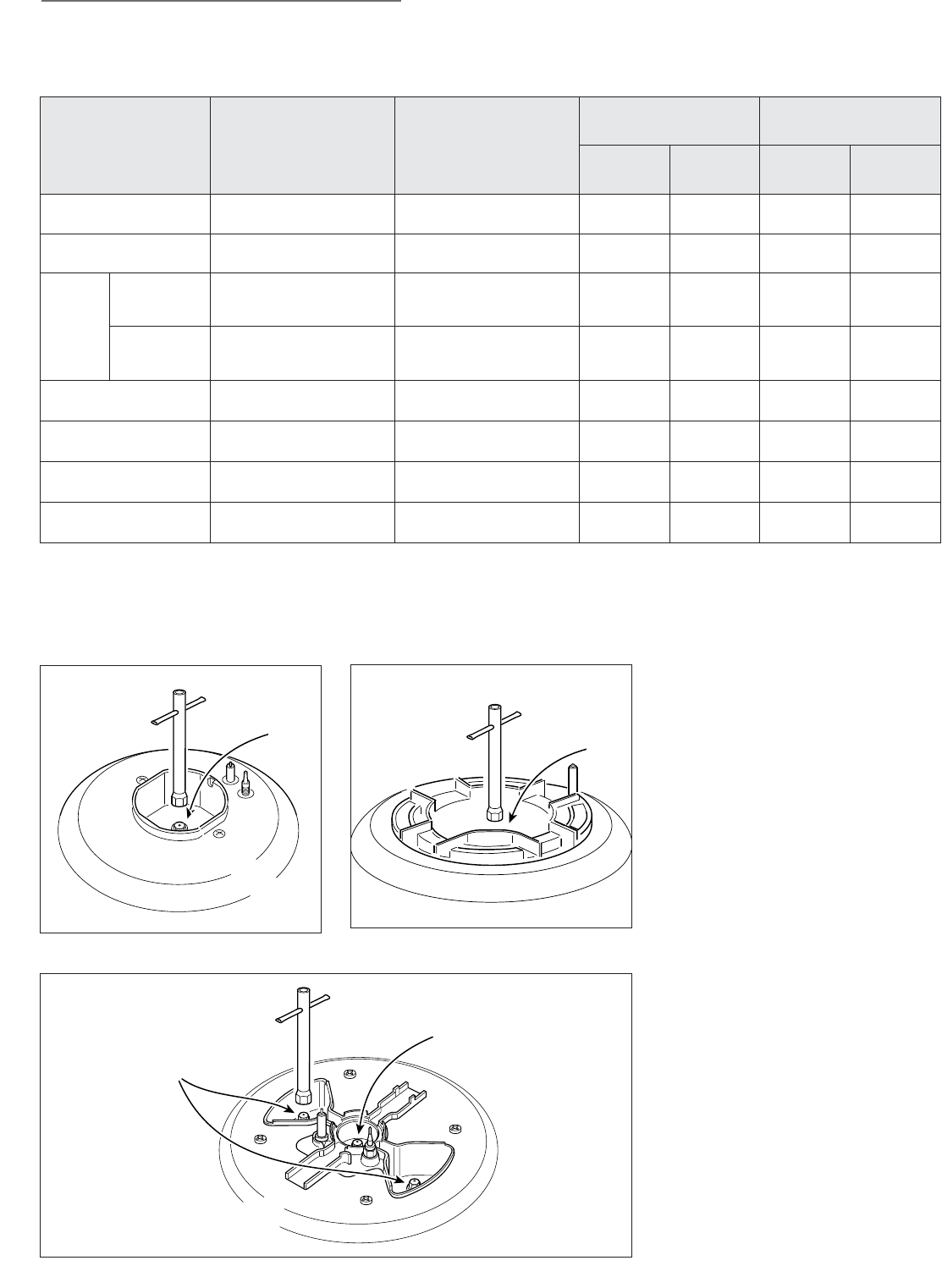

✓ Using a wrench substitute the nozzle

injectors “J” (figs. 2.6a - 2.6b - 2.6c)

with those most suitable for the kind of

gas for which it is to be used.

The burner are conceived in such a

way so as not to require the regulation

of the primary air.

Fig. 2.6a

Fig. 2.6b

Fig. 2.6c

INJECTORS TABLE

Semi-rapid

burner

Triple ring

burner

DUAL

burner

BURNERS

NOMINAL POWER

BTU/hr

REDUCED POWER

BTU/hr

LP/PROPANE

11” W.C.P.

NATURAL GAS

4” W.C.P.

Ø injector

[1/100 mm]

By-pass

[1/100 mm]

Ø injector

[1/100 mm]

By-pass

[1/100 mm]

Semi-rapid (R)

6000 1500 72 32 118

adjustable

Triple ring (TC)

12000 5000 102 65 170

adjustable

Oven burner (left)

13000 1500 109 34 180

adjustable

Oven burner (right)

9000 1400 88 33 145

adjustable

Broil burner (left)

8500 - 88 - 146 -

Broil burner (right)

8000 - 83 - 140 -

Dual (D)

Inner crown

2800 for NATURAL GAS (*)

3500 for LP/PROPANE GAS (*)

1000 (*)

55

(no. 1 central)

27

80

(no. 1 central)

adjustable

Outer crowns

16000 for NATURAL GAS (#)

15000 for LP/PROPANE GAS (#)

6500 for NATURAL GAS (#)

4500 for LP/PROPANE GAS (#)

72

(no. 2 outer)

60

130

(no. 2 outer)

adjustable

J

Injector for inner crown

J

Injectors for

outer crowns

J

J

(*) Power calculated only with inner crown operating

(#) Power calculated with inner and outer crowns operating