20

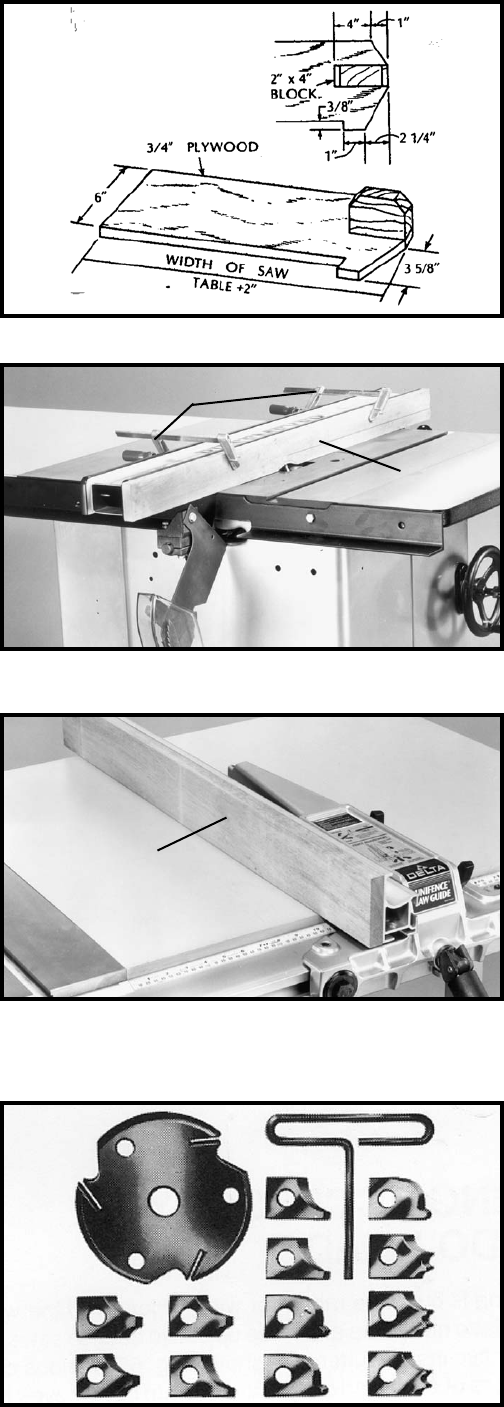

Fig. 61

USING AUXILIARY WOOD

FACING ON BIESEMEYER

RIP FENCE

It is necessary when performing special operations such

as moulding to add wood facing (A) Fig. 62, to one or

both sides of the rip fence, as shown. The wood facing is

attached to the fence with two clamps (B). 3/4 inch stock

is suitable for most work although an occasional job may

require 1 inch facing.

A wood facing should be used when ripping thin material

such as paneling to prevent the material from catching

between the bottom of the rip fence and the saw table

surface.

Fig. 62

B

A

Fig. 64

USING ACCESSORY

MOULDING CUTTERHEAD

Moulding is cutting a shape on the edge or face of the

work. Cutting mouldings with a moulding cutterhead in

the circular saw is a fast, safe and clean operation. The

many different knife shapes available make it possible for

the operator to produce almost any kind of mouldings,

such as various styles of corner moulds, picture frames,

table edges, etc.

The moulding head consists of a cutterhead in which can

be mounted various shapes of steel knives, as shown in

Fig. 64. Each of the three knives in a set is fitted into a

groove in the cutterhead and securely clamped with a

screw. The knife grooves should be kept free of sawdust,

which would prevent the cutter from seating properly.

USING AUXILIARY WOOD

FACING ON THE UNIFENCE

Fig. 63

It is necessary when performing special operations such

as when using the moulding cutterhead to add wood

facing (A) Fig. 63, to one side of the rip fence as shown.

The wood facing is attached to the fence with wood

screws through holes you drill in the fence. A suitable

stock size for most work is 3/4", although an occasional

job may require one inch facing.

A

When ripping boards longer than three feet, it is

recommended that a work support be used at the rear of

the saw to keep the workpiece from falling off the saw

table.

If the ripped work is less than 4 inches wide, a push stick

should always be used to complete the feed, as shown in

Fig. 60. The push stick can easily be made from scrap

material as explained in the section “CONSTRUCTING A

PUSH STICK.” When ripping material under 2 inches in

width, a flat pushboard is a valuable accessory since

ordinary type sticks may interfere with the blade guard.

That flat pushboard can be made as shown in Fig. 61.