General Instructions

Sealed Combustion Unit

The sealed canbustion unit is made up of the burner, a fresh air intake and

exhaust pipes, and a vent/air-intake assembly in the wall.

The burner unit is completely sealed off’

from the interior of the van by means

of the two special inlet and outlet pipes.

In the vent /air-intake assembly,

fresh air is drawn in one pipe and combusted gases are safely vented to the

outside through the other pipe.

Ventilator (Cooling Fan)

In order to improve the cooling performance under the difficult built-in situ-

ation and high ambient temperatures,

a o,6 W ventilator is switched on auto-

matically when the temperature around the

condenser

fins (behind the refri-

gerator) reaches

140~

F and switched off at 124 F.

NOTE:

The ventilator is connected to the 12 V-circuit in such a manner that it is

also operational during the 120 V and gas operations.

Fuse

For 12 V use the refrigerator is protected by a fuse installed in the gene-

ral electrical circuit of the vehicle. If the fuse bums out, trace the cause

and correct it before fitting a new lo amp. fuse.

Steps To Take When The Refrigerator Has Not Been Used For A Long Period

If there has been a heavy rain,or the vehicle has been through a car wash,

water may have collected in the burner housing. This must

be_

removed before

the gas is lit.

For this, the sealing plug underneath the front of the refri-

gerator on the left is unscrewed from the drainage tube and the water is

allowed to escape.

The sealing plug must then be carefully refitted since a

good seal is essential for the proper function of the combustion system._ Check

that the windscreen of the outside wall of the van is clean and remove any

dirt that is present.

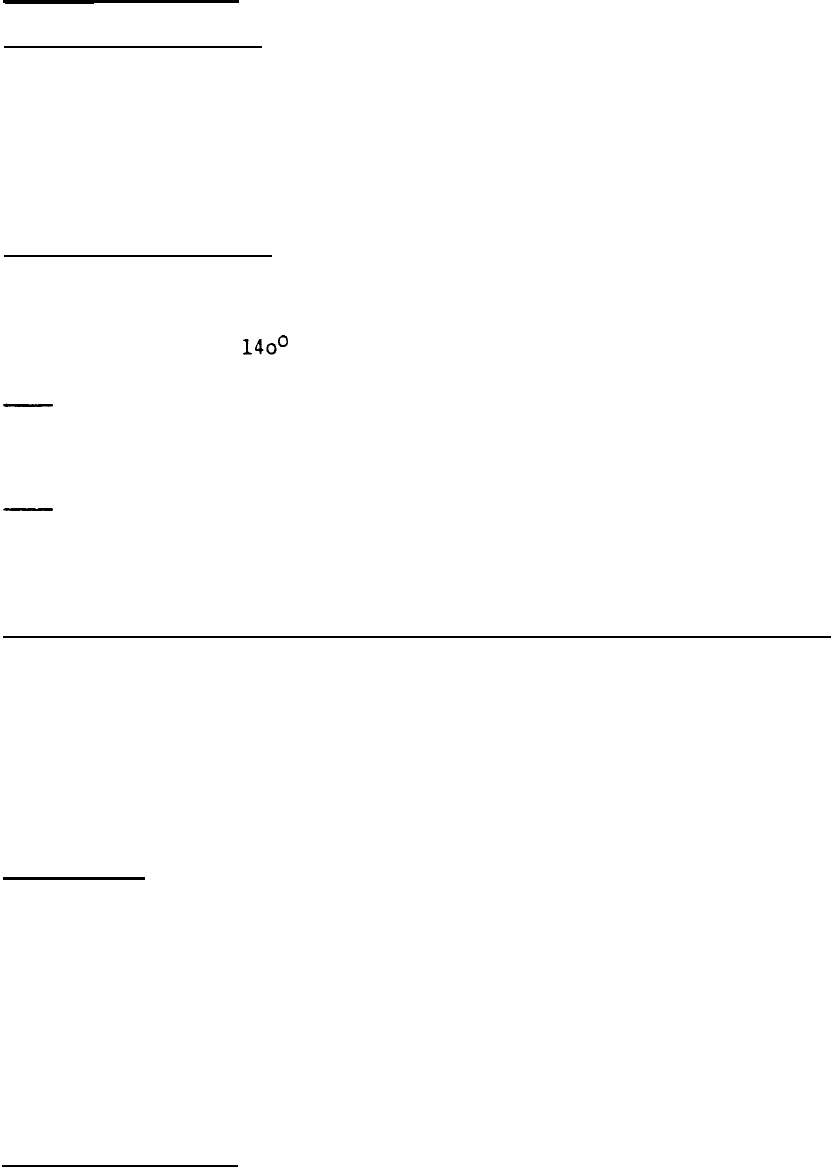

Pilot Outage

It has been determined that this problem can be causedbya poor seal between

the slide for ventilation housing

"E"

(Fig.2) and the side wall of the ve-

hicle.

When properly sealed,

this plate acts as a baffle to protect the exhaust out-

let tube from direct air flow. If this seal is not complete, air will be

allowed to flow between the plate and the side wall of the vehicle directly

into the exhaust outlet tube.

This problem can be caused by failure to tighten the mount

"D"

(Fig. 2) screws

properly, a bad gasket

"F"

(Fig.2) or a warped locating plate

"E"

(Fig. 2).

Periodic Maintenance

Once or twice a year, depending on use,

it is necessary to clean and adjust

the burner assembly.

The burner ist fitted with a # 24 jet, which is suitable for use on Propane

or Butane gas at a supply pressure of 11 inches water column pressure. The

orifice in the jet is very small and must never be cleaned by means of a pin

or a similar instrument for this will damage the orifice. Should, for

some

reason,

the jet require cleaning,

it should be washed in alcohol and blown

dry with air.

The entire gas installation should be checked for leaks. Test all pipe connec-

tions with soapy water, not with an open flame.

-4-