20

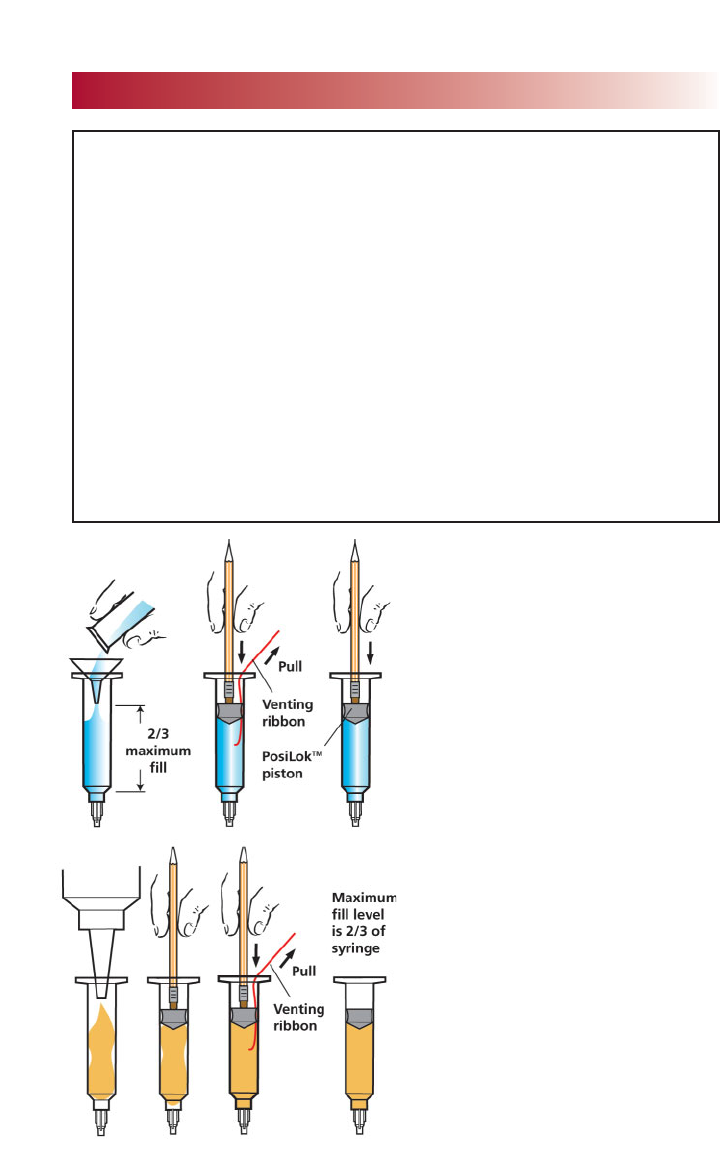

Pourable Fluid

Twist on a tip cap and pour your

fluid into the barrel using a funnel.

Insert a Venting Ribbon along the

inside edge of the barrel, followed

by an AirFree™ piston. Carefully

press down until it contacts the

fluid. While holding the piston in

place gently pull the Venting

Ribbon from the barrel.

Thick or Non Leveling Fluid

If the fluid comes packed in a

caulking cartridge try loading the

reservoir with a caulking gun. If

not, spoon-feeding with a spatula

often works. Follow the loading by

inserting the Venting Ribbon along

the inside of the barrel, followed

by AirFree™ piston. Carefully

press down to move the fluid to

the bottom of the barrel and to

remove trapped air. While holding

the piston in place gently pull the

Venting Ribbon from the barrel.

Loading the Reservoirs

Avoid Air in the Syringe Barrel

Trapped air in the fluid creates voids that will make the fluid

compressible. Although the LDS9000 Linear Drive System is

stable enough to handle most compressible fluids excess air will

force the user to use a greater amount of pullback. This will create

a greater amount of forward and reverse motion in the syringe

during a dispense cycle. Excess motion will put more stress on the

fluid being dispensed. The goal is to reduce dispense motion as

much as possible to protect the fluid and maximize repeatability.

Paying attention to minimization during syringe filling will

drastically improve performance.

For best results, use a Fishman barrel filing station (see next page).

If needed, use a centrifuge or vacuum chamber to eliminate any

trapped air.