SERVICING

66

S-106 OVERFEEDING

Overfeeding by the expansion valve results in high suction

pressure, cold suction line, and possible liquid slugging of the

compressor.

If these symptoms are observed:

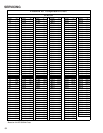

1. Check for an overcharged unit by referring to the cooling

performance charts in the servicing section.

2. Check the operation of the power element in the valve as

explained in S-110 Checking Expansion Valve Operation.

3. Check for restricted or plugged equalizer tube.

S-107 UNDERFEEDING

Underfeeding by the expansion valve results in low system

capacity and low suction pressures.

If these symptoms are observed:

1. Check for a restricted liquid line or drier. A restriction will

be indicated by a temperature drop across the drier.

2. Check the operation of the power element of the valve as

described in S-110 Checking Expansion Valve Operation.

S-108 SUPERHEAT

The expansion valves are factory adjusted to maintain 8 to 12

degrees superheat of the suction gas. Before checking the

superheat or replacing the valve, perform all the procedures

outlined under Air Flow, Refrigerant Charge, Expansion Valve

- Overfeeding, Underfeeding. These are the most common

causes for evaporator malfunction.

CHECKING SUPERHEAT

Refrigerant gas is considered superheated when its tempera-

ture is higher than the saturation temperature corresponding

to its pressure. The degree of superheat equals the degrees

of temperature increase above the saturation temperature at

existing pressure. See Temperature - Pressure Chart on

following pages.

CAUTION

To prevent personal injury, carefully connect and

disconnect manifold gauge hoses. Escaping liquid

refrigerant can cause burns. Do not vent refrigerant

to atmosphere. Recover during system repair

or final unit disposal.

1. Run system at least 10 minutes to allow pressure to

stabilize.

2. Temporarily install thermometer on suction (large) line

near suction line service valve with adequate contact and

insulate for best possible reading.

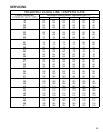

3. Refer to the superheat table provided for proper system

superheat. Add charge to lower superheat or recover

charge to raise superheat.

Superheat Formula = Suct. Line Temp. - Sat. Suct. Temp.

EXAMPLE:

a. Suction Pressure = 143

b. Corresponding Temp. °F. = 50

c. Thermometer on Suction Line = 61°F.

To obtain the degrees temperature of superheat, subtract

50.0 from 61.0°F.

The difference is 11° Superheat. The 11° Superheat would fall

in the ± range of allowable superheat.

SUPERHEAT AND SUBCOOLING ADJUSTMENT ON TXV

APPLICATIONS

1. Run system at least 10 minutes to allow pressure to

stabilize.

2. Temporarily install thermometer on liquid (small) line

near liquid line service valve with adequate contact and

insulate for best possible reading.

3. Check subcooling and superheat. Systems with TXV

application should have a subcooling and superheat of

7 ± 2ºF.

a. If subcooling and superheat are low, adjust TXV

to 7 - 9ºF then check subcooling.

b. If subcooling is low and superheat is high, add

charge to raise subcooling to 7 ± 2ºF then check

superheat.

c. If subcooling and superheat are high, adjust TXV

valve to 7 ± 9ºF then check subcooling.

d. If subcooling is high and superheat is low, adjust

TXV valve to 7 to 9ºF superheat and remove

charge to lower the subcooling to 7 ± 2ºF.

The TXV should NOT be adjusted at light load conditions

55º to 60ºF, under such conditions only the subcooling

can be evaluated. This is because suction pressure is

dependent on the indoor coil match, indoor airflow, and

wet bulb temperature. NOTE: Do NOT adjust charge

based on suction pressure unless there is a gross

undercharge.

4. Disconnect manifold set. Installation is complete.

S-109 CHECKING SUBCOOLING

Refrigerant liquid is considered subcooled when its tempera-

ture is lower than the saturation temperature corresponding

to its pressure. The degree of subcooling equals the degrees

of temperature decrease below the saturation temperature at

the existing pressure.

1. Attach an accurate thermometer or preferably a thermo-

couple type temperature tester to the liquid line as it

leaves the condensing unit.

2. Install a high side pressure gauge on the high side (liquid)

service valve at the front of the unit.

3. Record the gauge pressure and the temperature of the

line.