SERVICING

69

NOTE: At least twelve (12) inches of the suction line

immediately out of the compressor stub must be discarded

due to burned residue and contaminates.

1. Remove compressor discharge line strainer.

2. Remove the liquid line drier and expansion valve.

3 Purge all remaining components with dry nitrogen or

carbon dioxide until clean.

4. Install new components including liquid line drier.

5. Braze all joints, leak test, evacuate, and recharge sys-

tem.

6. Start up the unit and record the pressure drop across the

drier.

7. Continue to run the system for a minimum of twelve (12)

hours and recheck the pressure drop across the drier.

Pressure drop should not exceed 6 PSIG.

8. Continue to run the system for several days, repeatedly

checking pressure drop across the suction line drier. If

the pressure drop never exceeds the 6 PSIG, the drier has

trapped the contaminants. Remove the suction line drier

from the system.

9. If the pressure drop becomes greater, then it must be

replaced and steps 5 through 9 repeated until it does not

exceed 6 PSIG.

NOTICE: Regardless, the cause for burnout must be deter-

mined and corrected before the new compressor is started.

S-120 REFRIGERANT PIPING

The piping of a refrigeration system is very important in

relation to system capacity, proper oil return to compressor,

pumping rate of compressor and cooling performance of the

evaporator.

POE oils maintain a consistent viscosity over a large tem-

perature range which aids in the oil return to the compressor;

however, there will be some installations which require oil

return traps. These installations should be avoided whenever

possible, as adding oil traps to the refrigerant lines also

increases the opportunity for debris and moisture to be

introduced into the system. Avoid long running traps in

horizontal suction line.

LONG LINE SET APPLICATION R-410A

This long line set application guideline applies to all AHRI

listed R-410A air conditioner and heat pump split system

matches of nominal capacity 18,000 to 60,000 Btuh. This

guideline will cover installation requirements and additional

accessories needed for split system installations where the

line set exceeds 80 feet in actual length.

Accessories for lines greater than 80 feet:

1. Crankcase Heater- a long line set application can

critically increase the charge level needed for a system.

As a result, the system is very prone to refrigerant

migration during its off-cycle and a crankcase heater will

help minimize this risk. A crankcase heater is required for

any long line application (50 watt minimum).

2. For all line set applications over 80 feet a TXV is recom-

mended. The subcooling should be 6º ± 2º.

3. Hard Start Assist- increased charge level in long line

applications can require extra work from the compressor

at start-up. A hard start assist device may be required to

overcome this.

4. Liquid Line Solenoid - a long line set application can

critically increase the charge level needed for a system.

As a result, the system is very prone to refrigerant

migration during its off-cycle and a liquid line solenoid will

help minimize this. A liquid line solenoid is recom-

mended for any long line application on straight cooling

units.

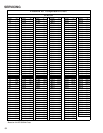

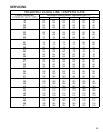

Tube Sizing:

1. In long line applications, the “equivalent line length” is the

sum of the straight length portions of the suction line plus

losses (in equivalent length) from 45 and 90 degree

bends. Select the proper suction tube size based on

equivalent length of the suction line (see Tables 4 &

5) and recalculated system capacity.

Equivalent length =

Length horizontal

+ Length vertical

+ Losses from bends (see Tables 4 & 5)

Example using ¾” elbow:

150 feet of straight tubing + (four short radius elbows

x 1.7) + (2 long radius elbows x 1.5) = 150 + 3.4 +3 =

156.4 equivalent feet.

2. For any residential split system installed with a long

line set, 3/8" liquid line size must be used. Limiting

the liquid line size to 3/8" is critical since an increased

refrigerant charge level from having a larger liquid line

could possibly shorten a compressor’s life-span.

3. Single Stage Condensing Unit: The maximum length

of tubing must not exceed 150 feet.

•80 feet is the maximum recommended vertical difference

between the condenser and evaporator when the evapo-

rator is above the condenser. Equivalent length is not to

exceed 150 feet.

• The vertical difference between the condenser and evapo-

rator when the evaporator is below the condenser can

approach 150 feet, as long as the equivalent length does

not exceed 150 feet.

• The distance between the condenser and evaporator in a

completely horizontal installation in which the indoor and

outdoor unit do not differ more than 10 feet in vertical

distance from each other can approach 150 feet, as long

as the equivalent length does not exceed 150 feet.