Installation

16 309572ZAG

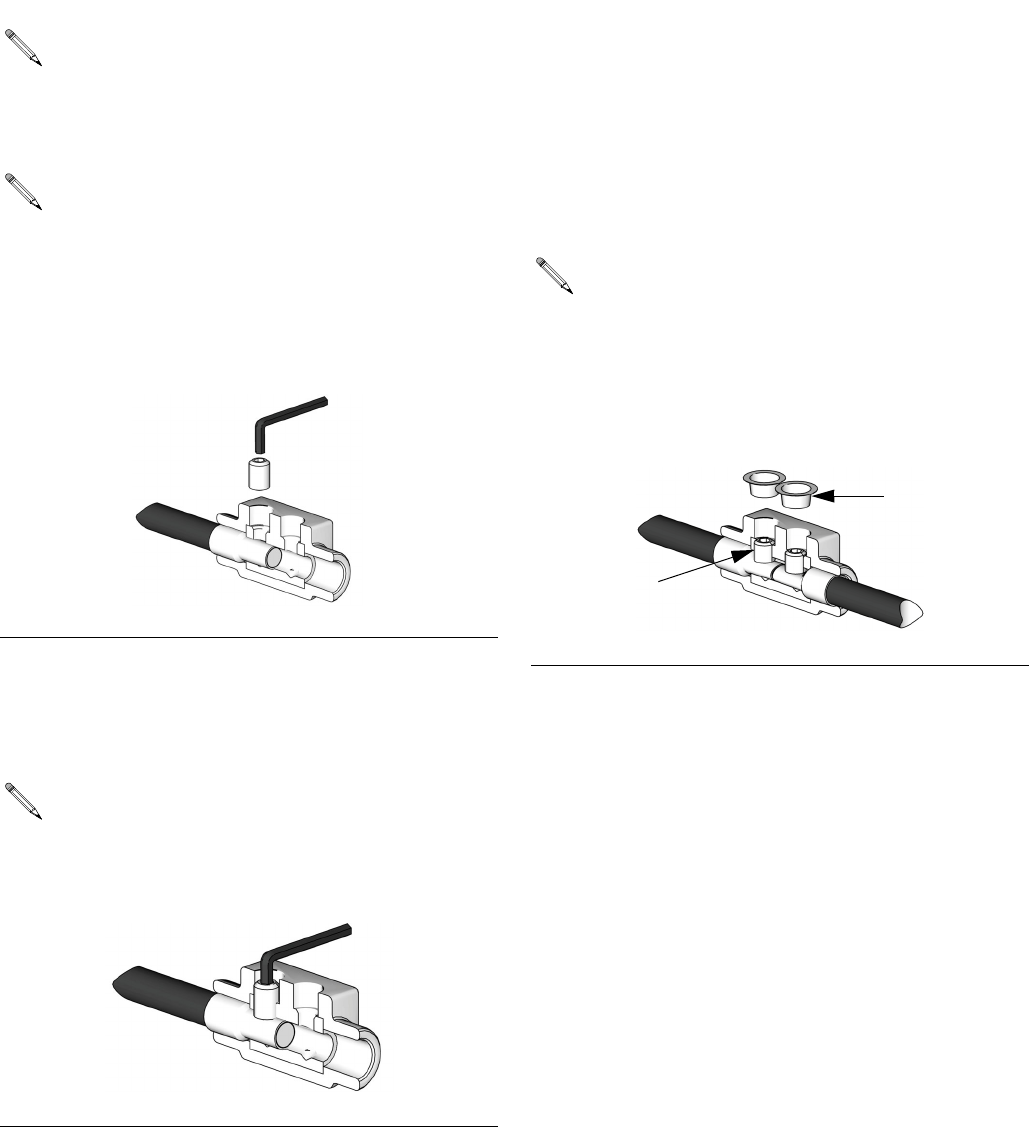

5. Connect the hoses to each other. Pair elec-

trical wires as follows: A-Hose to A-Hose;

B-Hose to B-Hose.

a. Insert one wire from heated hose into

connector. Ensure that ferrule is mating

with connector insert. See F

IG

. 8.

b. Thread in setscrew and use hex wrench

to torque setscrew to 60 in-lbs (6.78

N•m).

c. Insert remaining wire from pair into con-

nector; ensure proper insertion depth.

Thread setscrew and torque to 60 in-lbs

(6.78 N•m); see sub-step B. See F

IG

. 8

and F

IG

. 9.

d. Repeat sub-steps A through C for

remaining wire pair.

e. Re-torque all four setscrews to 60 in-lbs

(6.78 N•m).

f. Insert cap plugs over setscrews. See

F

IG

. 10.

g. Wrap connector and wire on each side

of connector in black electrical tape to

help seal out moisture. Ensure 1 in.

(25.4 mm) of wire on each side of con-

nector is wrapped.

When connecting first hose section to

proportioner, wire pairing does not make

a difference.

When connecting hose to the propor-

tioner, always check the hoses for leaks

(see page 21).

F

IG

. 8: Insert Wire and Setscrew

To reach approximately 60 in-lbs (6.78

N•m), complete 4.5 revolutions with hex

wrench after setscrew comes in contact

with ferrule.

F

IG

. 9: Torque Setscrew

TI9770A

TI9779A

When torqued to 60 in-lbs (6.78 N•m)

setscrews will be approximately flush

with connector. See F

IG

. 10.

F

IG

. 10

Cap plugs

Setscrews

TI9771A