Installation

309572ZAG 21

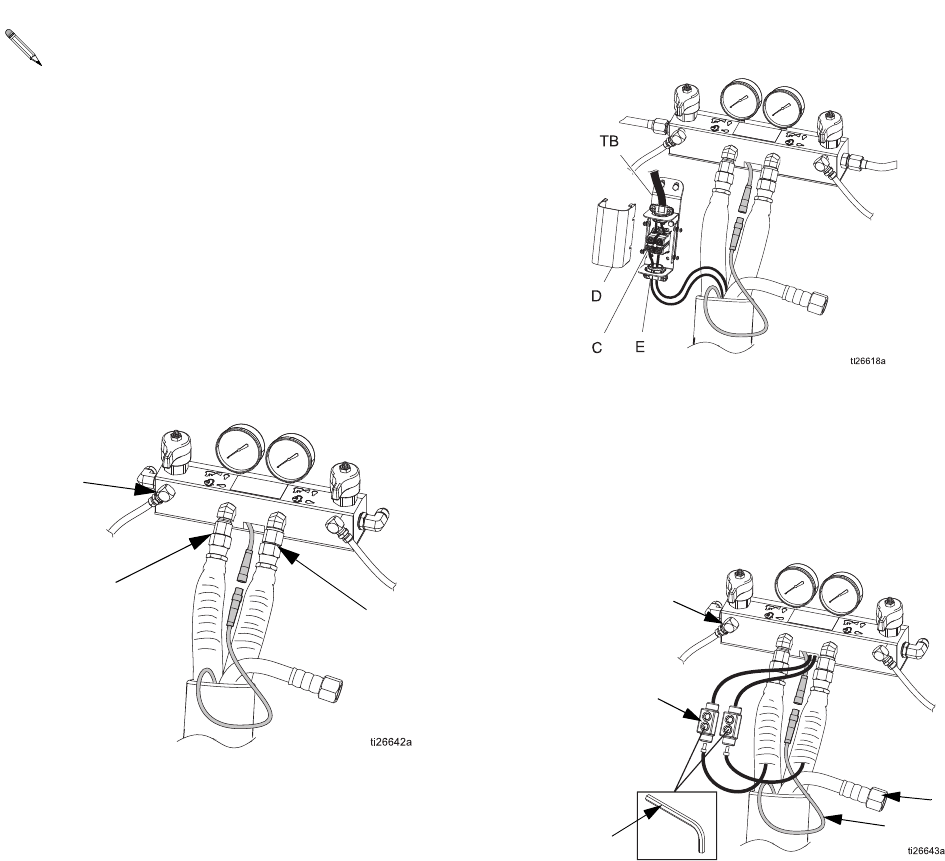

Connect Hoses to Proportioner

1. Grease with Fusion

®

grease and connect fluid

hoses to proportioner fluid manifold (M). Red

for hardener (ISO), blue for resin (RES).

NOTE: For proportioners with termination box

(TB), follow step 2, For proportioners with electrical

splice connectors (12) follow step 3.

2. Connect hose power wires to terminal block (C)

on termination box (TB). Remove box cover (D)

and loosen lower strain relief (E). Route wires

through strain relief and fully insert into terminal

block (A and B hose wire positions are not

important). Torque terminal connector screws

(C) to 26-30 in-lb (2.9-3.3 N•m). Fully tighten

strain relief screws and replace cover.

3. Connect hose power wires to electrical splice

connectors (12) from proportioner or accessory

control box. See Connect Heated Hoses,

page 14, step 5. Connect FTS hose cable (4) to

cable from proportioner or accessory control

box. Wrap connections with electrical tape.

4. Connect FTS cable connectors. Fully tighten

RTD connectors, if provided.

If thermocouple (non-RTD) FTS connectors are

provided, fully tighten connectors and slide

connector covers over the joint.

5. Check that all equipment is properly grounded.

See proportioner manual.

The manifold hose adapters (N, P) allow use

of 1/4 in (6.4 mm). and 3/8 in. (9.5 mm) ID

fluid hoses. To check adapter tightness,

torque 1/4 in. and 3/8 in. ID hoses to:

• A side (N) to 14 ft-lb (19 N•m).

• B side (P) to 20 ft-lb (27 N•m).

To use 1/2 in. (13 mm) ID fluid hoses,

remove the adapters (N, P) from the propor-

tioner fluid manifold and install them in the

FTS or 3/8 in. ID hose inlets. Torque 1/2 in.

ID hoses to:

• A side (N) to 43 ft-lb (58 N•m).

• B side (P) to 55 ft-lb (74 N•m).

M

N

P

M

4

3

12

T