6

Model PVe Heat Recovery Unit

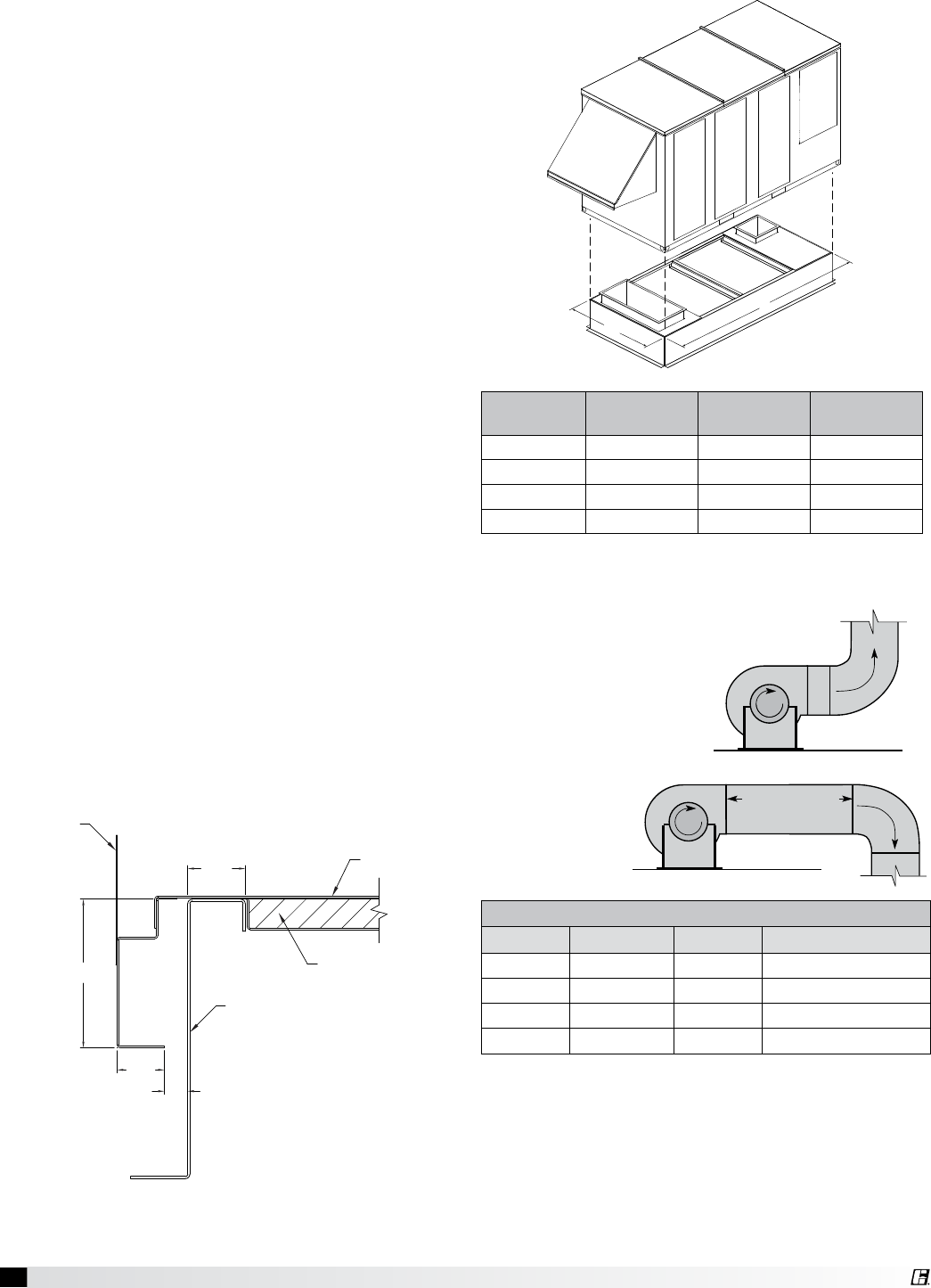

Roof Curb Mounting

Roof curb assembly and mounting instructions are

contained in the Roof Curb Assembly Instructions

supplied with Model GKD roof curb.

Rooftop PVe units require curbs to be mounted first,

in accordance with their appropriate instructions.

Curb unit is to be installed and then duct connections

are to be made prior to setting of the unit.

1. Factory Supplied Roof Curbs: Roof curbs are

Model GKD. The GKD ships in a knockdown kit

(which includes duct adapter) and requires field

assembly by others. Assembly instructions are

included with the GKD curbs.

2. Install Curb: Locate the assembled curb over

roof opening and verify precise location of curb

relative to the roof opening, in accordance with

dimensions given previously. Fasten curb loosely

in place and then shim as needed to ensure a

level installation. Tighten roof fastening hardware

and then re-check for level. Verify that diagonal

dimensions of installed curb are plus or minus

1/8-inch of each other.

3. Install Ductwork: Install needed ductwork in

accordance with SMACNA and AMCA guidelines.

Duct adapter is provided to support ducts prior

to setting the unit.

4. Install Insulation: One-inch deep insulation

pans are provided with the curb assembly. Set

the insulation pans per instructions and then

install insulation in the pans prior to setting

the unit. Insulation is not provided by the unit

manufacturer, it is to be supplied by others.

5. Set the PVe Unit: Lift unit to a point directly

above the curb and duct openings. Guide unit

carefully while lowering in order to align with duct

openings. The roof curb will seat in a recess in

the base of the PVe unit. Verify that the unit is

properly seated on the curb and is level.

Unit Size L W

Curb Weight

(lbs.)

PVe-20 99.4 36.8 195

PVe-35 99.4 44.6 216

PVe-45 105.9 56.3 261

PVe-55 111.7 71.3 316

All dimensions are shown in inches.

Curb Cap Details for Factory Supplied Roof Curbs

Ductwork Connections

Examples of poor and good fan-to-

duct connections are

shown below. Airflow

out of the fan should

be directed straight or

curve the same direction

as the fan wheel rotates.

Poor duct

installation will

result in low

airflow and other

system effects.

1 Fan

Wheel

Dia.

1 Fan

Wheel

Dia.

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Length of Straight Duct

GOOD

POOR

GOODPOOR

GOOD

POOR

Turning

Vanes

Turning

Vanes

SYSTEM EFFECT FACTOR CURVES

FPM X 100

OUTLET VELOCITY

0 5 10 15 20 25 30 35 40 45

1.2

1.0

0.8

0.6

0.4

0.2

0.0

STATIC PRESSURE LOSS

CURVE 1

CURVE 2

CURVE 3

CURVE 4

L

W

Curb Dimensions and Weights

4.844

1.549

0.775

Insulation Pan

Unit Base

Roof Curb

Dimensions are shown in inches.

1.895

Unit Side

Recommended Discharge Duct Size and Length

Unit Size Blower Size Duct Size Straight Duct Length

PVe-20 9 14 x 14 36

PVe-35 10 20 x 20 36

PVe-45 12 20 x 20 36

PVe-55 15 28 x 28 60

All dimensions are shown in inches.

• Recommended duct sizes are based on velocities across the

cfm range of each model at approximately 800 feet per minute

(FPM) at minimum airflow and up to 1600 fpm at maximum

airflow. Recommended duct sizes are only intended to be a

guide and may not satisfy the requirements of the project.

Refer to plans for appropriate job specific duct size and/or

velocity limitations.

• Straight duct lengths were calculated based on 100% effective

duct length requirements as prescribed in AMCA Publication

201. Calculated values have been rounded up to nearest foot.

1 Fan

Wheel

Dia.

1 Fan

Wheel

Dia.

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Length of Straight Duct

GOOD

POOR

GOODPOOR

GOOD

POOR

Turning

Vanes

Turning

Vanes

SYSTEM EFFECT FACTOR CURVES

FPM X 100

OUTLET VELOCITY

0 5 10 15 20 25 30 35 40 45

1.2

1.0

0.8

0.6

0.4

0.2

0.0

STATIC PRESSURE LOSS

CURVE 1

CURVE 2

CURVE 3

CURVE 4