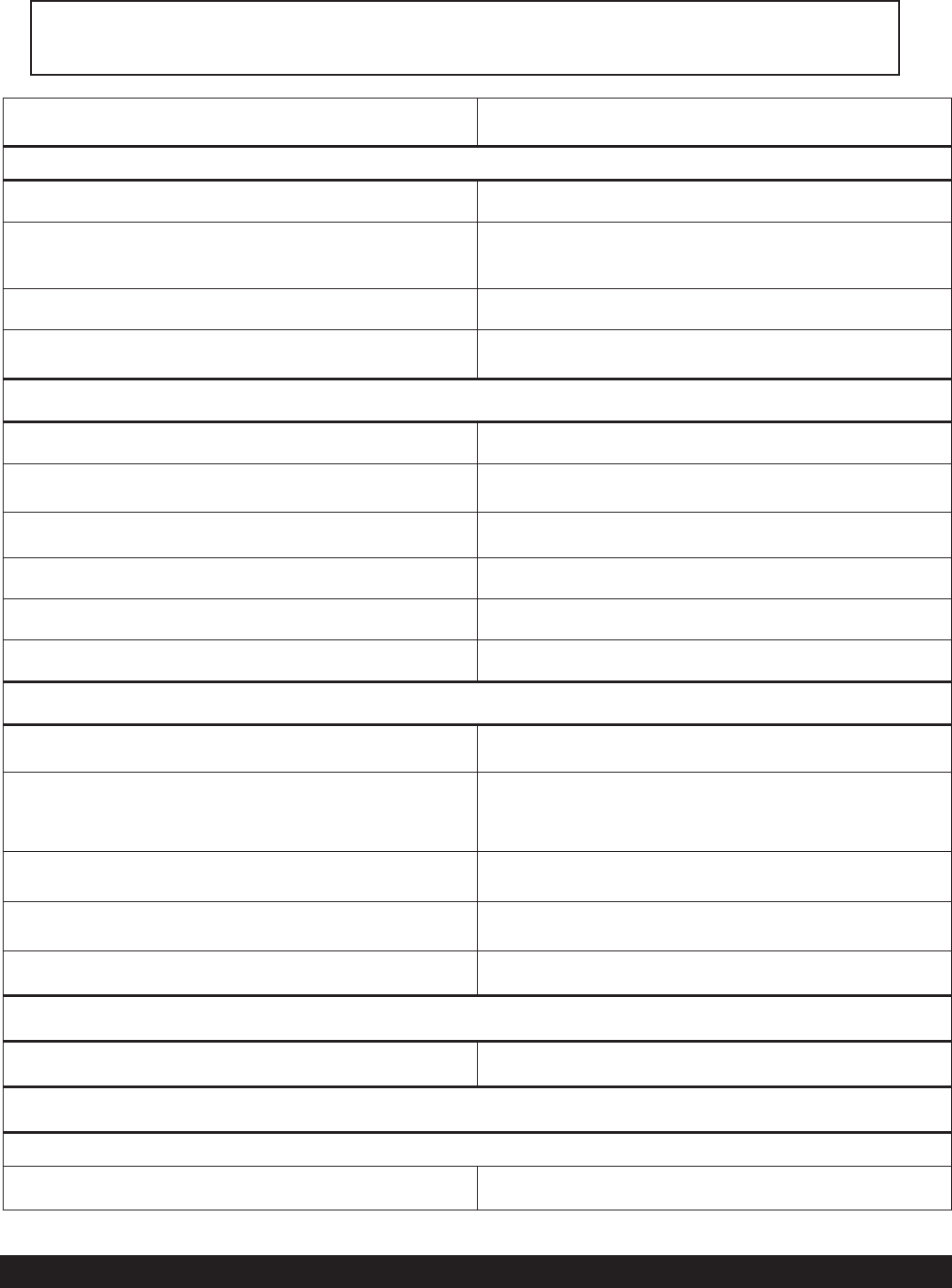

Page 17 Model LCD-2R and LCD-2A

Troubleshooting Guide (cont.)

ƽ

WARNING:

Risk of electrical shock. Disconnect power before removal of any machine access panels.

Problem/Cause Remedy

MACHINE DOES NOT POWER UP

Machine is unplugged Ensure machine is plugged into power supply

Power switch in OFF position Flip power switch to “ON” position (located at lower right corner

of back of machine); Blue LCD on door should be illuminated

when ON.

Branch circuit breaker has tripped Reset circuit breaker at service supply panel

Power supply external fuse is blown Check and replace fuse if necessary (located behind lower right

side chassis access panel).

NO HOT WATER FROM DISPENSE HEAD

Faulty water tank heater Check heating element resistance; replace if necessary.

Water Fill circuit “watch dog timer” has tripped Turn power switch “OFF” for 5 seconds, then “ON” (located at

lower right corner of back of machine)

Water supply to machine is turned OFF

Check for flashing diagnostic lights on control board See diagram of control for explanation of lights.

Level probe sensitivity is too high

Water is disabled in programming Check “Engineer” programming to ensure water is enabled.

NO CONCENTRATE IS DISPENSED

Bag-in-Box is empty or disconnected Ensure Bag-in-Box is not empty; replace with new Bag-in-Box if

empty.

Bag-in-Box connector is pointing up. (This position can create a

partial vacuum in the concentrate tube which may prevent

product from being pumped to the dispense spout.)

Position Bag-in-Box connector pointing down to provide a

positive pressure in the concentrate tube.

Concentrate pickup tube is kinked Inspect tubing routing and ensure concentrate tubing is not

kinked.

Concentrate pump tubing, product out switch, or Bag-in-Box

fitting is clogged.

Periodically clean and sanitize tubing per the cleaning and

sanitizing procedure in the instruction manual.

“Coffee” is disabled in programming. Check “Engineer” programming to ensure “Coffee” is enabled.

WATER TANK OVERFLOWS THROUGH TANK VENT AT BOTTOM OF MACHINE

Weeping fill valve seat Call for service.

WATER TANK OVERFLOWS THROUGH TANK VENT AT BOTTOM OF MACHINE

Note: A secondary float switch located in the water tank is intended to indicate an overflow condition at the LCD display.

Weeping water inlet valve Check water inlet valve; replace if necessary. (Note: a slow

overflow indicated this condition.)