-4- G7153 Universal Bender

OOPPEERRAATTIINNGG PPRROOCCEEDDUURREESS

Your tool is capable of many different types of

bending operations. Materials which can be

shaped include steel, iron, brass, wrought iron

and aluminum.

To determine how to properly set the tool up, you

first must determine what type of bending opera-

tion you wish to perform. Round shapes, angles

or spiral operations are each described in the

following sections. The numbers in parentheses

relate to the reference number on the exploded

parts view on page 8.

When performing the bending operations, be

aware of the “spring-back” characteristic of cer-

tain materials. This will require that you overbend

the material to a certain degree to end up with the

desired degree of bend. Different materials have

differing degrees of springback. Do a test bend to

determine how much “spring-back” you will need

to compensate for.

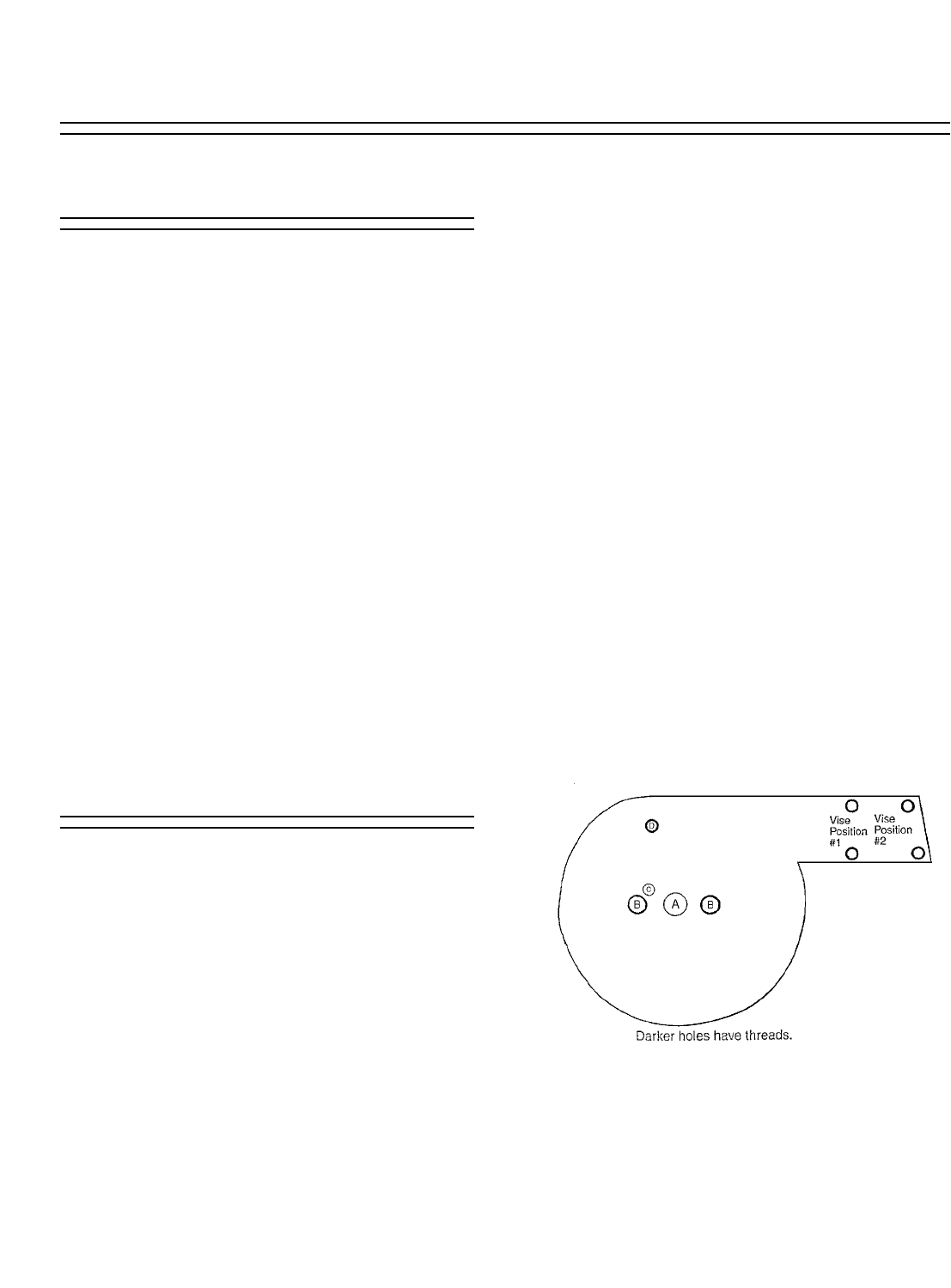

GGeenneerraall

11..

Make sure the Die Mounting Plate (4) is

attached to the Body. Refer to

FFiigguurree 11

for the

hole positions needed for Round Operations.

22..

Make sure the Stop (2) is loose.

33..

Move the Vise Assembly (5-9 & 15) to the rear

position on the arm of the Mounting Plate.

44..

Screw the Round Die Mounting Shaft (28) into

the Mounting Plate.

55

. Set the Round Die (29) onto the Mounting

Shaft.

66

. Move the Bending Block Assembly (16, 17,

22-24) back all of the way. You may have to

release the Bending Block Locking Plate (21)

by loosening the two Hex Key Bolts (20). Do

not secure the Locking Plate at this time.

RRoouunndd OOppeerraattiioonnss

77..

Set stock against the Round Die and close the

Vise so that it clamps the work securely

against the Die.

88..

Move the Bending Block in until it is up against

the work and its Face (16) is even with the

Vise Face (8). Secure the Bending Block by

tightening the two Bolts.

99..

Move the Bending Block to the left with the

Handle (27) until you have achieved your

desired angle bend, remembering to account

for “spring-back”.

1100..

If you wish to do repeat bends at the same

arc, tighten the Stop at the point where you

finished making your bend and tighten it.

1111..

When you wish to do complete 360° rings,

make sure you clamp the very end of your

workpiece in-between the Vise and the Die.

Bend your stock all the of the way around, and

cut off the excess.

1122..

To make springs, loosen the Stop (2), and lift

the stock to be formed slightly as you bend the

stock around the Die. When starting and fin-

ishing the spring, make a complete 360° ring

as described in Step #11.

FFiigguurree 11..

Die Mounting Plate Hole Location

(A) Insert Round Die Mounting Shaft here

(B) Insert Hex Key Bolts here

(C) Insert Angle Die Spring here

(D) Insert Angle Die Hex Bolt here