18

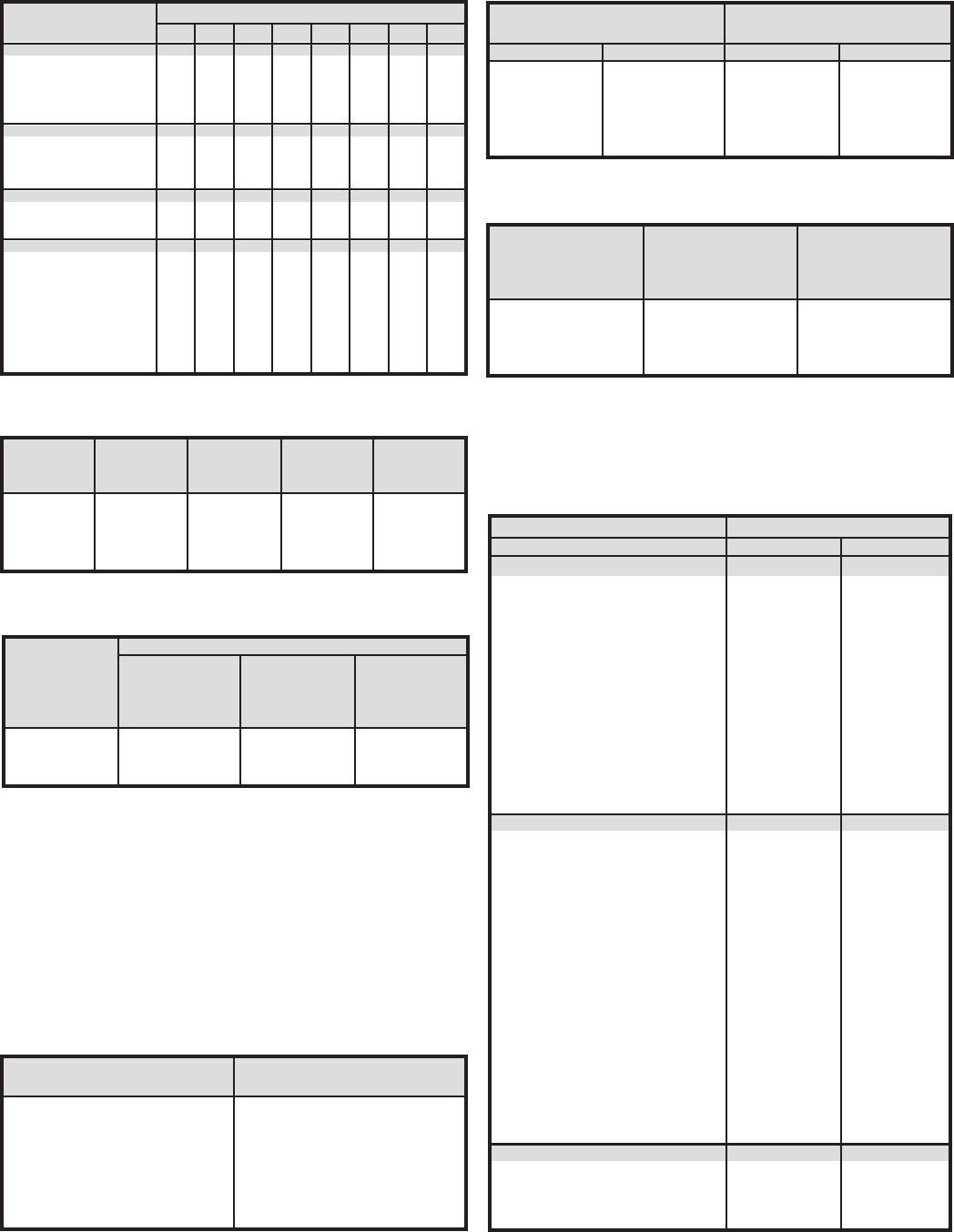

Table 9

Heat Loads of Keg and Bottled Beer (BTU / 24 HR)

Type and Size Temperature Reduction of Beer only. ºF.

of Container 60 50 40 30 20 15 10 5

Wood

One Keg — — 12000 9000 6000 4500 3000 1500

Half Keg — — 5600 4650 3100 2325 1550 775

Quarter Keg — — 3200 2400 1600 1200 800 400

Eighth Keg — — 1640 1230 820 615 410 205

Aluminum

Half Keg — — 5200 3900 2600 1950 1300 650

Quarter Keg — — 2560 1920 1280 960 640 320

Eighth Keg — — 1400 1050 700 525 350 175

Steel

Half Keg — — 4800 3600 2600 1800 1200 600

Quarter Keg — — 2400 1800 1200 900 600 300

Bottles

6 oz. 32 27 22 16 10.8 8.1 5.4 2.7

7 oz. 37 31 25 20 124 9.3 6.2 3.1

8 oz. 42 35 28 21 14.0 10.5 7.0 3.5

9 oz. 47 38 30 23 15.2 11.4 76 3.8

12 oz. 60 50 40 30 20 15 10 5.0

Cases of 24 - 12 oz.

Bottles/Cans 1920 1600 1280 960 640 480 320 160

Table 13

General standard for insulation thickness in storage rooms

ºF. ºC. Styrofoam Urethane

-50º to -25º -45º to -32º 8 6

-25º to -0º -32º to -18º 6 4

0º to 25º -18º to -4º 4 4

25º to 40º -4º to 5º 4 3 - 4

40º and up +5º and up 2 2

Storage Desirable Insulation

Temperature Thickness in Inches

Battery Heat Gain Approximate

operated per hour of total weight

load capacity truck operation of lift truck

lb. BTU / hr.* lb.

2,000 14,000 6,000

4,000 21,000 8,000

6,000 23,000 12,000

8,000 26,000 14,000

Table 14

Heat gain due to operation of battery operated lift truck

* Heat gain from lift trucks with internal combustion engines can

be approximated by multiplying the engine horsepower by 2,545

by the number of hours of operation (BTU/24 Hrs.)

Average Entering Final

Weight Specic Carcass Carcass

Carcass lbs. Heat Temp. ºF. Temp. ºF.

Cattle 550 0.77 106 35

Calves 150 0.76 104 35

Sheep 45 0.76 101 33

Hogs 180 0.54 106 35

Table 12

Heat equivalent of Occupancy

BTU per (HP) (HR)

Motor Connected

Connected Losses Load

Motor Load In Outside Outside

HP Refr Space

1

Refr Space

2

Refr Space

3

1/8 to 1/2 4,250 2,545 1,700

1/2 to 3 3,700 2,545 1,150

3 to 20 2,950 2,545 400

Table 10

Carcass Weight

1

For use when both useful output and motor losses are dissipated

within refrigerator space: motors driving fans for forced circulation

unit coolers.

2

For use when motor losses are dissipated outside refrigerated space

and useful work of motor is expended within refrigerated space:

pump on a circulating brine or chilled water system, fan motor out-

side refrigerated space driving fan circulating air within refrigerated

space.

3

For use when motor heat losses are dissipated within refrigerated

space and useful work expended outside of refrigerated space: motor

in refrigerated space driving pump or fan located outside of space.

Cooler Heat Equivalent / Person

Temperature ºF. BTU / 24 Hrs.

50 17,280

40 20,160

30 22,800

20 25,200

10 28,800

0 31,200

-10 33,600

Table 11

Heat equivalent of electric motors

Table 15

Specic heats of various liquids and solids

Liquids

Acetic Acid 0.522 79 - 203

Alcohol-Ethyl 0.680 32 - 208

Alcohol-Methyl 0.610 59 - 68

Calcium Chloride

Brine (20% by wt.) 0.744 68

Carbon

Tetrachloride 0.201 68

Chloroform 0.234 68

Gasoline 0.500 32 - 212

Glycerine 0.575 59 - 120

Olive Oil 0.471 44

Toluene 0.404 68

Turpentine 0.420 68

Solids

Aluminum 0.214 —

Asphalt 0.220 —

Bakelite 0.350 —

Brickwork 0.200 —

Brass 0.090 —

Bronze 0.104 —

Concrete 0.156 —

Glass 0.200 —

Ice 0.465 -4

Ice 0.487 32

Iron (Cast) 0.120 —

Lead 0.031 —

Paper 0.320 —

Porcelain 0.180 —

Rubber Goods 0.480 —

Sand 0.191 —

Steel 0.120 —

Woods

Fir 0.650 —

Oak 0.570 —

Pine 0.670 —

Specic Heat

Name BTU/lb./ºF. Temp ºF.