D896 AUTOMATIC VENT DAMPER

68-0186

4

IMPORTANT

1. The atmospheric draft hood outlet area must be

smaller or equal to the inlet area of the damper

assembly.

2. If a second gas valve needs to be installed, refer

to the gas valve manufacturer instructions for the

procedure.

3. Using a dual automatic valve combination gas

control or two separate gas valves is required

with the D896.

4. Do not use with L8148 or L8124 with manual/

automatic switch because the switch can override

the safety interlock in the system wiring and

cause a hazardous condition.

5. Do not install on an appliance equipped with an

automatic valve with a manual opener unless the

manual opener is rendered inoperative or the

automatic valve is replaced with an automatic

valve without a manual opener.

6. On retrofit applications, installation identification

label (provided) must be filled out by installer and

applied to outside of cover.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could cause a hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained experienced service

technician. The D896 must be installed in compliance

with local codes or the Natural Gas Installation Code

CAN/CGA-B149.1-B149.1-M91 and CSA C22.2 #3

Electrical Features of Fuel Burning Equipment, or the

National Fuel Gas Code (ANSI Z223.1—NFPA 54) and

the National Electrical Codes (ANSI C1—NFPA70). Use

the ANSI Standard Z21.66-1994 included at the end of

this specification during installation.

NOTE: In Canada, the damper is not certified for

retrofit application. Certification for the

suitability of the damper and appliance

combination must be determined by the

Canadian Gas Association.

4. Install only on an appliance connected to a factory built

chimney or vent that complies with a recognized

standard, or to a masonry or concrete chimney that is

lined with a material acceptable to local code.

5. After installation is complete, check out product

operation as provided in the Checkout section. See

Exhibits A and B at the end of this specification.

CAUTION

Can cause electrical shock or equipment damage.

1. Disconnect power supply.

2. Do

not

install within 6 in. (152 mm) of combustible

materials.

3. Do

not

negate the action of any existing safety or

operational control.

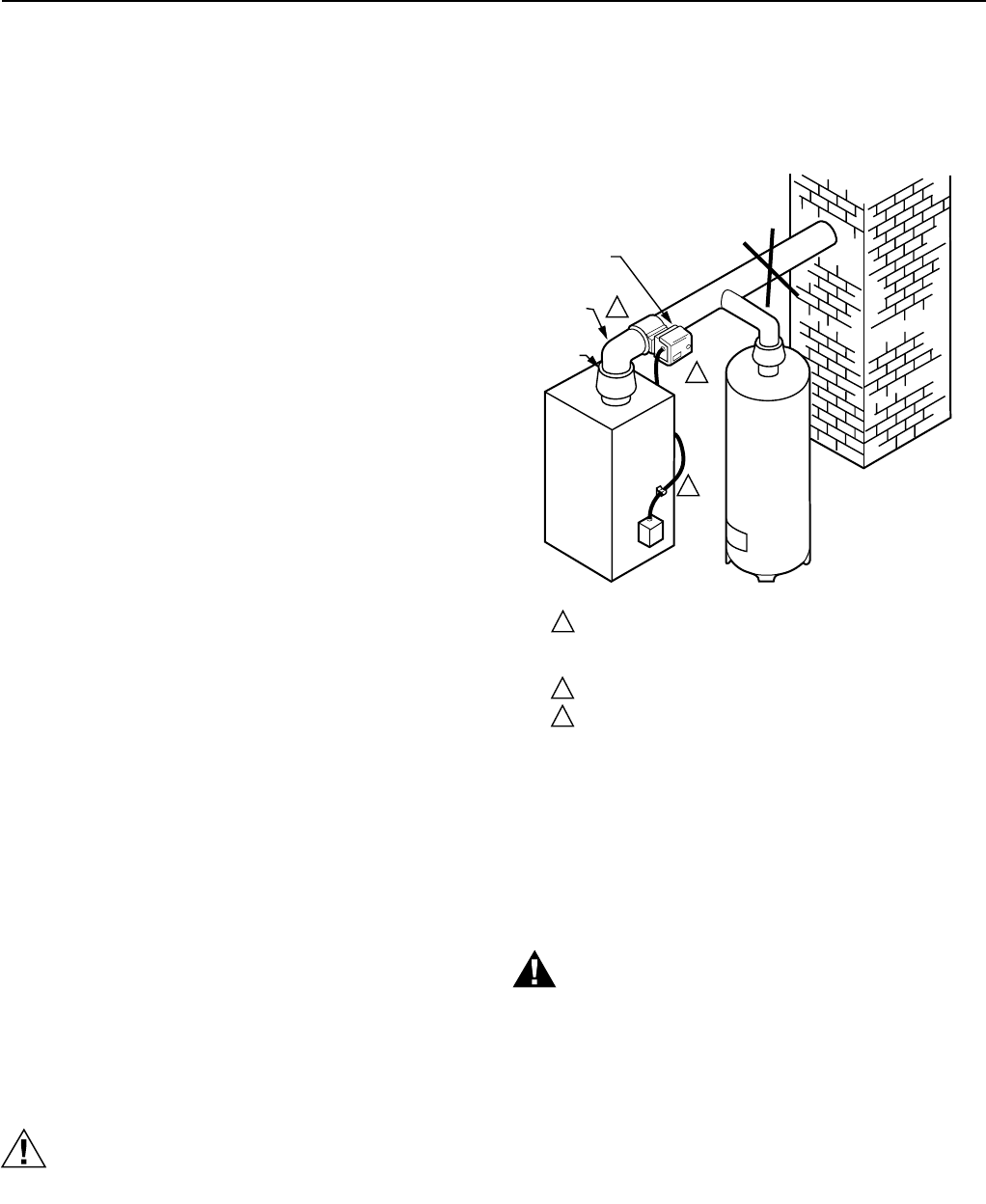

Location

The D896 must be installed

after

the furnace or boiler draft

hood. See Fig. 2. Make sure the D896 Motor Actuator is

readily visible and accessible. The damper must be located

where air can freely circulate around it.

M11370

2

1

3

WARNING: DO NOT INSTALL THE

VENT DAMPER WITHIN 6 IN. (152 mm)

OF COMBUSTIBLE MATERIAL.

NO

CHIMNEY

WATER HEATER

FURNACE OR BOILER

INSTALL THE VENT DAMPER TO SERVICE ONLY THE SINGLE

APPLIANCE FOR WHICH IT IS INTENDED. IF IMPROPERLY

INSTALLED, A HAZARDOUS CONDITION, SUCH AS AN EXPLOSION

OR CARBON MONOXIDE POISONING, COULD RESULT.

DO NOT INSTALL THE VENT DAMPER ON VENT PIPE CURVE.

DO NOT RUN WIRES NEAR HIGH TEMPERATURE SURFACES.

USE STAND-OFF BRACKETS IF NECESSARY.

2

1

3

VENT PIPE

CURVE

DRAFT

HOOD

D896 MOTOR

ACTUATOR

Fig. 2. D896 location.

Do

not

install the D896:

— Where the stack temperature is higher than 575°F (284°C).

— Where the ambient temperature is higher than 150°F

(66°C).

— In small or enclosed spaces where temperature can

exceed 150° F (66°C). See WARNING following.

— On the vent pipe curve. See Fig. 2.

WARNING

Severe illness or death possible. Prevent

explosion or carbon monoxide poisoning.

Overheating can cause premature device failure. Be

sure the D896 is used to control only one appliance.

Mounting

The damper must be mounted as close as possible to the

draft hood without modifying the draft hood. The D896 can be

mounted vertically or horizontally. When vertically mounting

the vent damper, the motor actuator can be in any position.

See Fig. 3.

Horizontal mounting requires the actuator to be located within

45 degrees directly above or directly below the horizontal

diameter of the stack pipe. See Fig. 2 and 3.