F76S WATER FILTERS AND MV876B AUTOMATIC-BACKWASH CONTROLS

5 62-3015—4

Commercial and Industrial Installations

(1-1/2 and 2 in. models)

Commercial and industrial installations have high flow

requirements. For proper operation, limit flow across the F76S

screen. For example, a two-inch pipe may have a 120 gpm flow

at 12 fps linear velocity across a clean screen. High linear

velocity impacts dirt deeply into the screen, making it difficult to

backwash and causing the screen to plug up quickly. In these

situations, install multiple F76 filters in parallel. See Fig. 3.

Fig. 3. Parallel installation of three F76S Water Filters.

Advantages of parallel installation:

• Increased cleaning capacity. Backwash interval is reduced.

• Elimination of system downtime. Can backwash one F76S

while the others maintain required flow.

Another consideration in commercial and industrial

installations is the backwash interval. Because of the high flow

requirements, screens need cleaning on a regular basis. An

MV876 Automatic-Backwash Control can be installed to back-

wash the F76S automatically.

INSTALLATION

CAUTION

Equipment Damage Hazard.

Excessive pressure or temperature can damage

the device.

Ensure water temperature and pressure are below

maximum ratings specified.

CAUTION

Equipment Damage Hazard.

Excessive heating can damage internal parts.

Before sweating, separate the tailpieces and nuts from

the filter body.

F76S

When installing an F76S, use the following procedure:

1.

Shut off water supply by closing the water supply valve.

2.

Install the F76S in the water line with the arrow pointing

in the direction of water flow.

3.

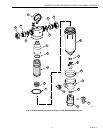

Install pressure gauge in the F76S center port (see Fig. 4).

IMPORTANT

When using an MV876, stop here and install the MV876.

4.

Ensure the F76S air vent is open.

5.

Slowly open the water supply valve.

6.

Once the F76S sump fills with water, close the air vent

and fully open the water supply valve.

Fig. 4. Installing the F76S.

MV876

When adding an MV876 to an existing F76, the procedure can

vary depending on the F76 model.

Installation on an F76S

1.

Open the backwash outlet ball valve.

2.

Remove the backwash outlet handle.

3.

Install the MV876. See Fig. 5 and 6.

NOTE: When you rotate the MV876, it closes the

backwash outlet ball valve.

4.

Ensure the F76S air vent is open.

5.

Slowly open the water supply valve.

6.

Once the F76S sump fills with water, close the air vent

and fully open the water supply valve.

7.

Program the desired backwash interval by pushing the

program button until the desired interval number

appears in the display.

100

150

50

0

200

Honeywell

Braukmann

INLET

PIPE

M17360

100

150

50

0

200

Honeywell

Braukmann

ISOLATION VALVE.

1

1

1

1

1

100

150

50

0

200

Honeywell

Braukmann

100

150

50

0

200

Honeywell

Braukmann

M16480