F76S WATER FILTERS AND MV876B AUTOMATIC-BACKWASH CONTROLS

62-3015—46

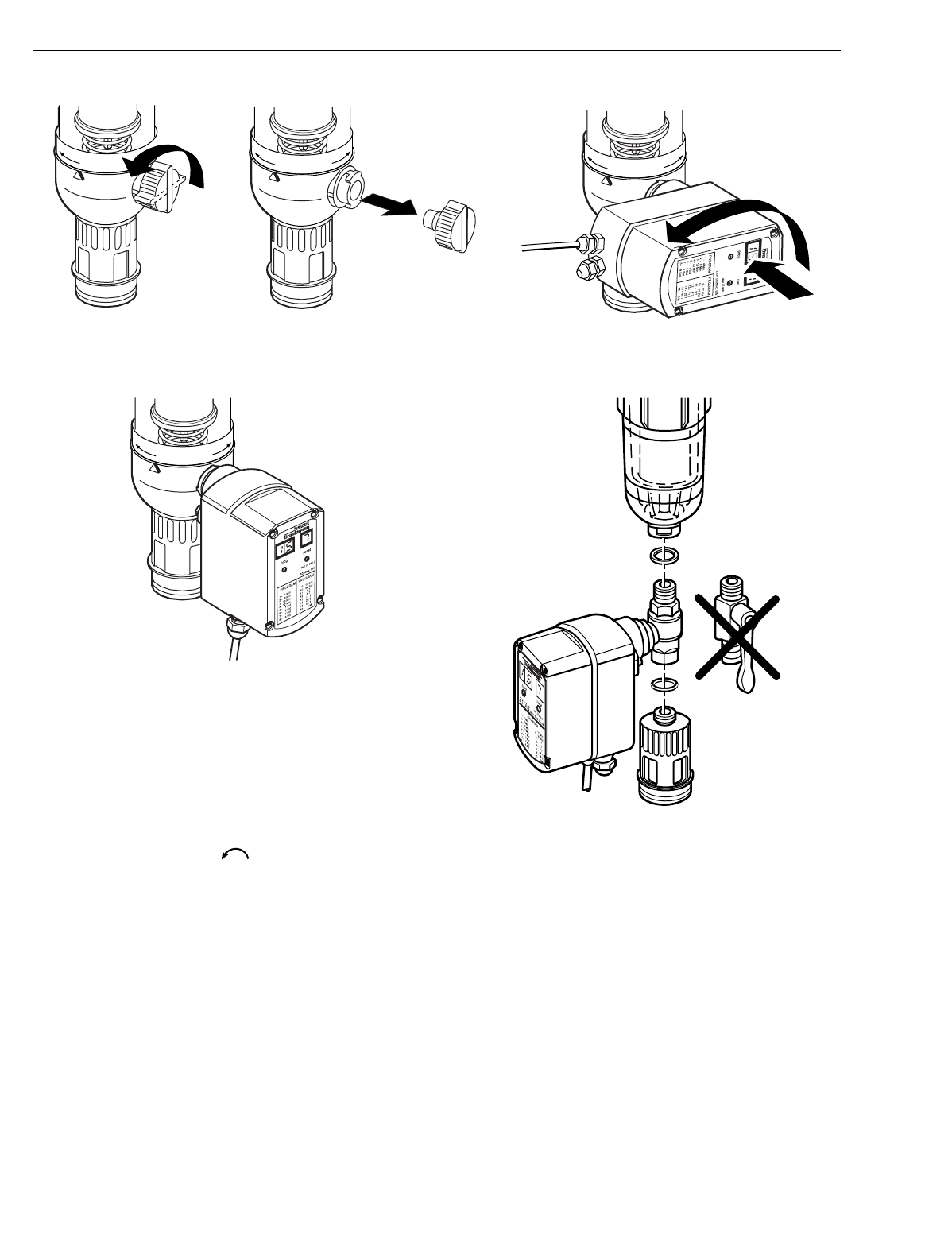

Fig. 5. Installing the MV876.

Fig. 6. Final position of MV876 and F76S components.

Installation on an F76A

1.

Close the water supply valve to shut off water supply.

2.

Drain all water from the F76A by opening both a fixture

downstream, and the backwash outlet; loosen the air

vent on top of the F76A.

3.

Remove the backwash outlet (see Fig. 7):

a. Grip the F76A fixture with a wrench.

b. Using another wrench, turn the outlet

counterclockwise (viewed from the bottom).

4.

Connect the MV876 to the F76A (see Fig. 7):

a. Ensure a plastic washer is placed between the filter

sump and the backwash outlet.

b. Connect the externally threaded portion of the

MV876 backwash outlet to the internally threaded

F76A connection.

5.

Connect the hose fitting to the MV876 backwash outlet

(see Fig. 7).

Fig. 7. Installing the MV876B on the F76A.

Set Pressure Gauge Needles

The black needle on the pressure gauge measures the F76S

outlet pressure. When the F76S is running with clean screens,

there is a small pressure drop across the F76S (3 psi at

maximum recommended flow).

The red needle is a stationary needle that helps monitor back-

wash interval.

NOTE: The following assumes a constant inlet pressure. If

inlet pressure is variable, another gauge on the inlet

piping, or the air vent will provide more information

regarding actual pressure differential.

1.

Backwash F76S once to ensure the screens are clean.

2.

With the F76S in operation, rotate the clear gauge cover

to set the red needle to match the black needle.

M16481

MV876B

M16483

MV876B

M17357