3

K. Bin Control Check

An infrared sensor is used as the primary bin control to control the level of ice in the

dispensing unit/storage bin. A mechanical bin control is used as a backup bin control.

IMPORTANT

1. Make sure the icemaker has been installed as outlined in this manual and

that the water supply is on.

. Make sure S1 Dip Switch 7 is in the "ON" position. This allows the control

board to monitor the infrared sensor along with the mechanical backup bin

control.

1. Infrared Sensor Check

1) Turn off the power supply.

) Remove the front panel, top panel, and control box cover.

3) Conrm that control board S1 dip switch 1, , and 3 are in the proper position for your

application. "See IV.K.3. Infrared Sensor Shutdown Delay."

4) Move the control switch on the control box to the "ICE" position, then move the power

switch to the "ON" position.

5) Turn on the power supply to start the automatic icemaking process. The green LED on

the infrared sensor turns on. This LED conrms 0V DC power to the sensor.

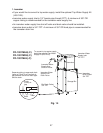

6) Make sure the "GM" LED on the control board is on. See Fig. 17. There is a delay of

at least 30 seconds before the "GM" LED turns on after power-up. After the "GM" LED

turns on, press the "SERVICE" button on the control board to bypass the 5-minute

compressor delay. WARNING! Risk of electric shock. Care should be taken not to

touch live terminals. The "COMP" LED turns on.

"SERVICE"

Button

S1 Dip Switch

"GM" LED

"COMP" LED

K6 - Connector for

Infrared Sensor

Fig. 17