10

6)

Check the water supply and drain connections for

water leaks.

7) Turn off the power supply, and remove the Front

Panel.

8)

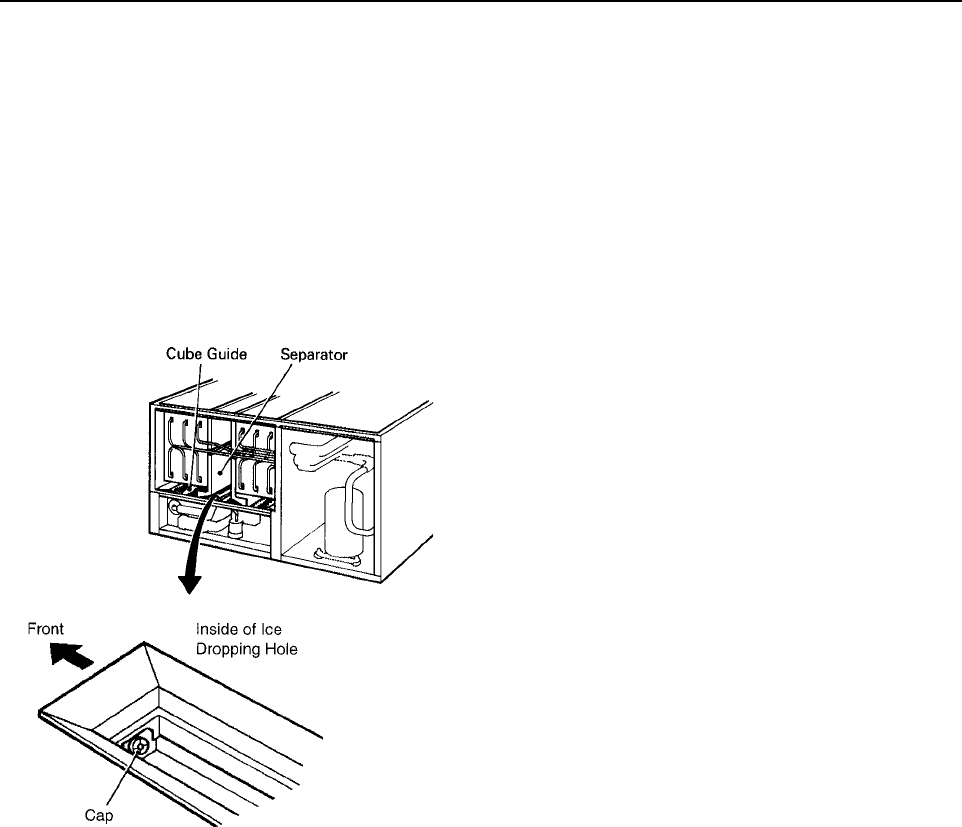

Remove the Insulation Panel. Remove the Cap

located on the front bottom part of the Ice Dropping

Hole. Drain the Water Tank to flush any loose

debris. See Fig. 12.

Fig. 12Fig. 12

Fig. 12Fig. 12

Fig. 12

9)

Replace the Cap, Insulation Panel and Front Panel

in their correct positions.

10)

Clean the Storage Bin.

11) Turn on the power supply, and start the

automatic icemaking process.

12) Wait until a complete icemaking and defrost cycle

is completed.

BIN CONTROL CHECKBIN CONTROL CHECK

BIN CONTROL CHECKBIN CONTROL CHECK

BIN CONTROL CHECK

1) With the Front Panel in place, remove the thumb-

screws along the upper edge of the storage bin ice

deflector and allow it to pivot on the side fixings.

2) Hold some ice against the Bin Control Bulb. The

icemaker should stop within 6 to 10 seconds.

3) Replace the thumbscrews and close the bin door.

4) Check that the icemaker re-starts.

10. OPERATION10. OPERATION

10. OPERATION10. OPERATION

10. OPERATION

The steps in the sequence are as follows:

1) 1 Minute Fill Cycle

The unit always starts in the 1 minute fill cycle. When

power is applied to the unit, the water valve is ener-

gized and the fill period begins. After 1 minute the

board checks for a closed float switch. If the float

switch is closed the harvest cycle begins. If not,

the unit will not start without adequate water in

the sump. This serves a low water safety shut off. The

water valve will remain energized through additional

1 minute cycles until water enters the sump and the

float switch closes.

2) 1st Harvest Cycle

The compressor starts, hot gas valve opens, water

valve remains open and harvest begins. As the

evaporator warms, the thermistor located on the

suction line checks for a 9°C temperature. When 9°C

is reached, the harvest is turned over to the adjust-

able control board defrost timer which is factory set

for normal conditions. This adjustment can vary the

defrost timer from 1 to 3 minutes.

3) Freeze Cycle

After the timer terminates the harvest cycle, the hot

gas and water valves close, and the ice production

cycle starts. For the first 5 minutes the controller

board will not accept a signal from the float switch.

This 5 minute minimum freeze acts as a short cycle

protection. At the end of 5 minutes the float switch

assumes control. As ice builds on the evaporator the

water level in the sump lowers. The freeze continues

until the float switch opens and terminates ice pro-

duction.

ENGLISH