14

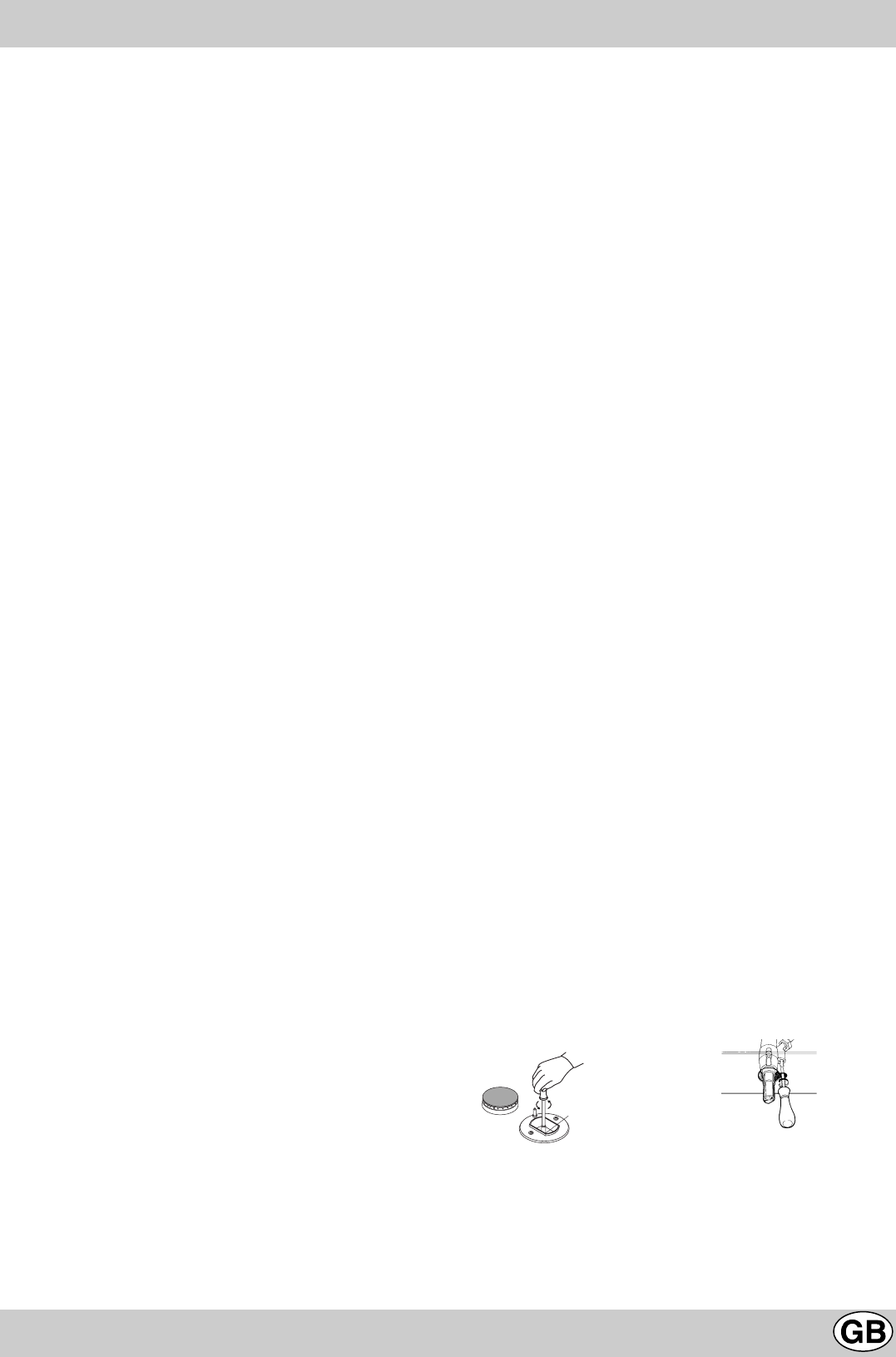

fig.9

fig.10

INSTALLATION

A

open window or a more efficient ventilation system by

increasing the extraction power of the electric fan if installed.

Liquid petroleum gas descends towards the floor as it is

heavier than air. Apertures in the outside walls in rooms

containing LPG cylinders should therefore be at floor level,

in order to allow any gas from leaks to be expelled. Do not

store LPG cylinders (even when empty) in basements or

rooms below ground level; it is advisable to keep only the

cylinder in use in the room at any one time and connected

far from heat sources which could raise its temperature to

above 50 °C.

Gas connection for the gas hob

The hob should be connected to the gas supply by a CORGI

registered installer. During installation of this product it

is essential to fit an approved gas tap to isolate the

supply from the appliance for the convenience of any

sebsequent removal or servicing. Connection of the

appliance to the gas mains or liquid gas must be carried

out according to the prescribed regulations in force, and

only after it has been ascertained that it is adaptable to

the type of gas to be used. If not, follow instructions

indicated in the paragraph headed, 'Adapting to different

types of gas'.

In the case of connection to liquid gas, in a cylinder, a

pressure regulator, that conform to the regulations in

force, must be inserted.

Important: for safety, for the correct regulation of gas

use and long life of the appliance, ensure that the gas

pressure conforms to the indications given in table 1,

'Burner and Nozzle Specifications'.

Connection to non-flexible tube

(copper or steel)

Connection to the gas source must be done in such a way

as to not create any stress points at any part of the

appliance. The appliance is fitted with an adjustable, 'L'

shaped connector and a gasket for the attachment to

the gas supply. Should this connector have to be turned,

the gasket must be replaced (supplied with the apliance).

The feeding connector of the gas to the appliance is

threaded 1/2" gas male cylinder.

Connection to flexible steel tube

The gas feed connector to the appliance is a threaded,

male

1/2" connector for round gas pipe. Only use pipes and

sealing gaskets that conform to the standards currently

in force.

• it should be as short as possible, with a maximum

length of 1.5 metres;

• it should not be bent or kinked;

• it should not be in contact with the rear panel of the

appliance or in any case with parts which may reach a

temperature of 50°.

• it should not pass through holes or slits used for dis-

charging the oven flue gases;

• it should not come into contact with pointed parts or

sharp corners;

• it should be easy to inspect along its entire length in

order to be able to check its condition;

• it should be replaced before the date printed on the

actual pipe.

Check the seal

Upon completion of installation, check for leaks from the

gas circuit using a soapy water solution (never use a

flame). Make sure that the natural gas pipe is adequate

for a sufficient supply to the appliance when all the

burners are lit.

Adapting to different types of gas (instructions for the

hob)

To adapt the hob to a different type of gas from the factory-

set one (indicated on the rating plate at the top of the

hood or on the packaging), the burner nozzles should be

replaced as follows:

• Remove the pan supports and slide the burners off their

seats.

• Unscrew the nozzles (fig. 9, using a 7 mm socket spanner

and replace them with nozzles for the new type of gas

(see table 1 "Burner and nozzle specifications").

• Reassemble the parts following the above procedure in

the reverse order.

• On completion of this operation, replace the old rating

label with the one indicating the new type of gas used.

This sticker is available from Hotpoint Service (see KEY

CONTACTS, back page).

Adjusting the primary air of the burners

The primary air of the burners does not need to be adjusted.

Adjusting the low flame

• Turn the tap to the low flame position;

• Remove the knob and turn the adjusting screw, situated

to the right of the tap (fig. 10) until you obtain a regular

small flame, using a screwdriver (loosening the screw

increases the height of the flame, tightening decreases

it).

N.B.: In the case of liquid gas, the regulation screw

must be screwed in all the way.

• Having obtained the low flame setting required and with

the burner lit, change the position of the knob several

times from minimum to maximum and vice versa and

check that the flame does not go out.

• In appliances fitted with the safety device

(thermocouple), should the device fail to work with the

burners set to the low flame setting, increase the low

flame setting of the same on the adjusting screw.

Once the adjustment has been made, remount the seals

on the by-passes using leak detection fluid.