Rev.0008

3

HUSSMANN CHINO PRODUCT CONTROL

The serial number and shipping date of all equipment has

been recorded in Hussmann’s files for warranty and re-

placement part purposes. All correspondence pertaining

to warranty or parts ordering must include the serial num-

ber of each piece of equipment involved, in order to pro-

vide the customer with the correct parts.

The Hussmann warranty is printed on the back

of this guide.

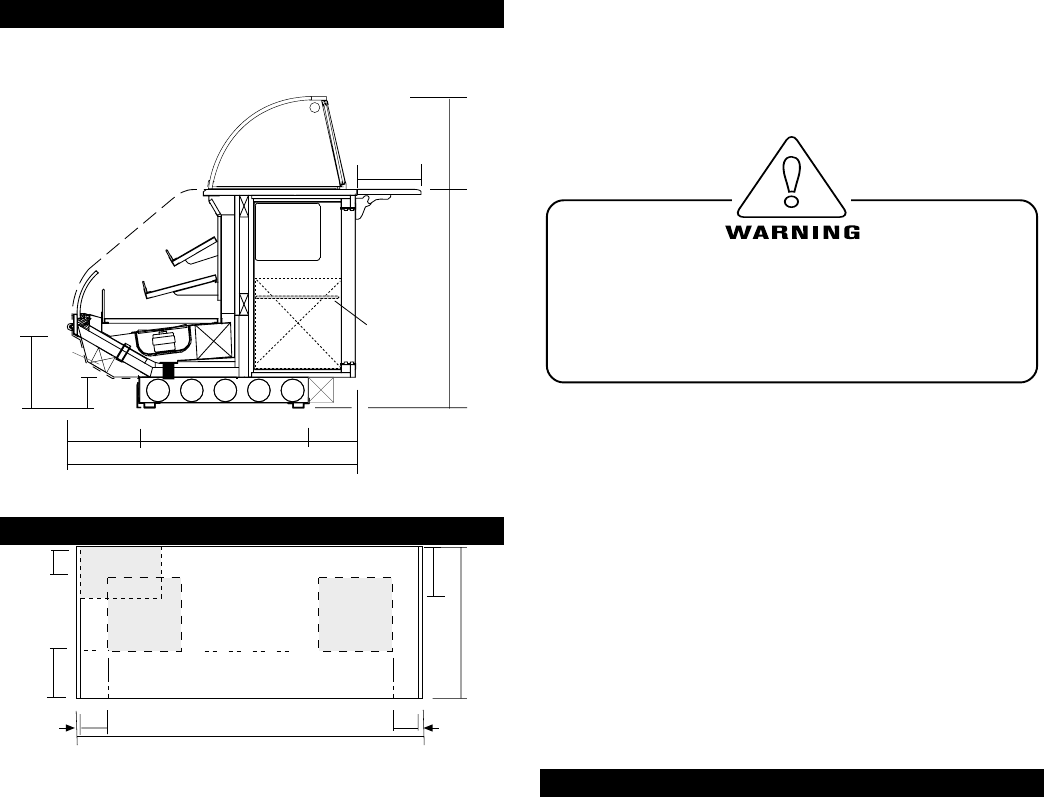

Cut & Plan Views

Plan View

48"

1"

1"

8"

8’-2" (4’-2”, 6’-2”)

CASE FRONT

8"

16"

8"

REFRIG.

MECHANICAL

STUB UP AREA

none

16"

Ref. Dome

(Optional)

Light

RGSSFP (S.C)

shown with Optional Refrigerated Rear Storage

Prep/Self-Service

*3

6

"

4

8

"

End

Panel

*1

2

"

1

2

"

30"

Adj. Wire

Racks

Coil

8

1

/

4

"

1

3

"

8"

12"

19

1

/

2

"

*5

"

Elec.

Access

9

7

/

8

"

Condensing

Unit

S.C.

CONDENSING

UNIT

DRAIN & ELEC.

MECHANICAL

STUB UP AREA

18" X 18"

In-

stallation

LOCATION

The refrigerated merchandisers have been designed for

use only in air conditioned stores where temperature and

humidity are maintained at or below 75°F and 55% rela-

tive humidity. DO NOT allow air conditioning, electric fans,

open doors or windows (etc.) to create air currents around

the merchandiser, as this will impair its correct operation.

Product temperature should always be maintained at a

constant and proper temperature. This means that from

the time the product is received, through storage, prepa-

ration and display, the temperature of the product must

be controlled to maximize life of the product.

UNCRATING THE STAND

Place the fixture as close to its permanent position as

possible. Remove the top of the crate. Detach the walls

from each other and remove from the skid. Unbolt the

case from the skid. The fixture can now be lifted off the

crate skid. Lift only at base of stand!

EXTERIOR LOADING

These models have not been structurally designed to sup-

port excessive external loading. Do not walk on their

tops; This could cause serious personal injury and dam-

age to the fixture.

AVOID REMOVING CONCRETE

All cases were leveled and joined prior to shipment to

ensure closest possible fit when cases are joined in the

field. To avoid removing concrete flooring, begin

lineup at highest point of store floor.

LEVELING

IMPORTANT! It is imperative that the case

be leveled from front to back and side to side

prior to joining. A level case is necessary to

insure proper operation.

JOINT TRIM

After the case has been leveled and joined, and refrigera-

tion, electrical, and waste piping work completed, install

the splashguards. Fasten along the top edge, or center, with

#10 X 3/8" sheet metal screws.

DO NOT SEAL JOINT T RIM T O FLOOR!

Plumbing

WASTE OUTLET AND P-TRAP

The waste outlet is located off the center of the case on

one side allowing drip piping to be run lengthwise under

the fixture.

A 1-1/2" P-trap and threaded adapter are supplied with

each fixture. The P-trap must be installed to prevent air

leakage and insect entrance into the fixture.

NOTE: PVC-DWV solvent cement is recommended.

Follow the manufacturer’s instructions.