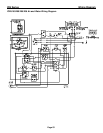

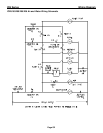

ICE Series Electrical System

Page F9

Undercounter machines: A thermostatic bin control is used on the undercounter models. The bin

thermostat is located in the control box with a capillary tube, which is in a brass thermo-well

mounted to the water trough. When ice comes in contact with the capillary tube thermo-well, the

bin thermostat opens and the machine will shut off.

Bin Control Adjustment

All Models (Except Undercounter Models): Check the bin switch for proper adjustment by

swinging the bottom of the curtain away from the evaporator. Slowly bring the curtain towards the

evaporator. The switch should close when the bottom edge of the curtain is even with the outer

edge of the water trough. Adjust the switch by loosening the screws the hold the switch in place.

Move the switch to the proper position and retighten the screws. Recheck the adjustment.

Adjustments are not covered under warranty.

Undercounter Models

Turn the machine to the ICE or WASH position. Hold ice against the brass thermal-well mounted

to the water trough making sure the ice is in contact with at least 6 inches (15 cm) of the thermal-

well. The machine should shut off in approximately 1 minute, remove the ice, the machine should

restart in approximately 3 minutes. If a major adjustment is required, turn the adjustment screw

counterclockwise (warmer) until it stops then turn the adjustment screw clockwise (colder) 1/8 of a

turn. This should put the control close to the proper adjustment, recheck and make a minor

adjustment if needed. If a minor adjustment is required, turn the adjustment screw clockwise

(colder) or counterclockwise (warmer). Adjustments are not covered under warranty.

Pump Down System (Remote Only)

If a remote machine is shut down by the selector switch or bin control, the liquid line solenoid valve

is de-energized allowing the valve to close. This blocks the flow of refrigerant causing all the

refrigerant to be pumped into the receiver and condenser. This is done to prevent liquid refrigerant

from migrating into the compressor during the off cycle, which could damage the compressor on

start-up. Also see Pump Down System in the Refrigeration Section on page E7. As the refrigerant

is pumped into the receiver, the suction pressure begins to drop. Once the suction pressure

reaches approximately 10 psi (.68 bar) the pump down control contacts open, which will de-

energize the compressor contactor. When the machine is turned back on, power is supplied to the

liquid line solenoid which opens the valve and allows the suction pressure to rise enough to close

the pump down controls contacts.

Pump Down Control

The pump down control is a low pressure control that shuts the machine off when the

suction pressure drops during the pump down phase. The control is factory set to open at

10 psi (.68 bar) and close at 30 psi (2.04 bar). The pump down control does not normally

need to be adjusted, however an adjustment may be made by turning the adjustment

screw. Note: Later model machines have a non adjustable pump down control.

Fan Control

On models utilizing a fan control, the fan will cycle on at 250 psi (17.01) and

cycle off at 200 psi (13.61 bar).