Continuous Flow Icemaker Service Manual

Publication Number: 630460324SER - 14 - © 2006, IMI Cornelius Inc.

ELECTRICAL CHECKOUT

1. Be sure the unit is disconnected from the power source. Remove the compressor electrical box

cover. Check for obvious damage and loose wires.

2. Disconnect the fan motor leads. Since capacitors store energy, short the capacitor with a

screwdriver. This will prevent shocks.

3. Disconnect the compressor terminal wires.

OVERLOAD CHECK

COMPRESSOR CHECK

CAPACITOR CHECK

SAFETY CONTROLS

Your icemaker unit has several safety and control devices incorporated into its design.

WARNING: None of the below described devices should ever be “bypassed” to allow the unit to

function.

The safety and control system shut–off devices are:

1. Low water shut off reed switch located in icemaker float assembly. (Automatic reset type.)

2. Gearmotor thermal overload, manual reset type (red button on motor).

3. Compressor thermal overload, automatic reset type.

4. Anti–freeze relay and associated circuit. See wiring diagrams.

5. Main service switch located on top of the control box.

6. Bin Control.

7. High pressure cut out (water cooled only).

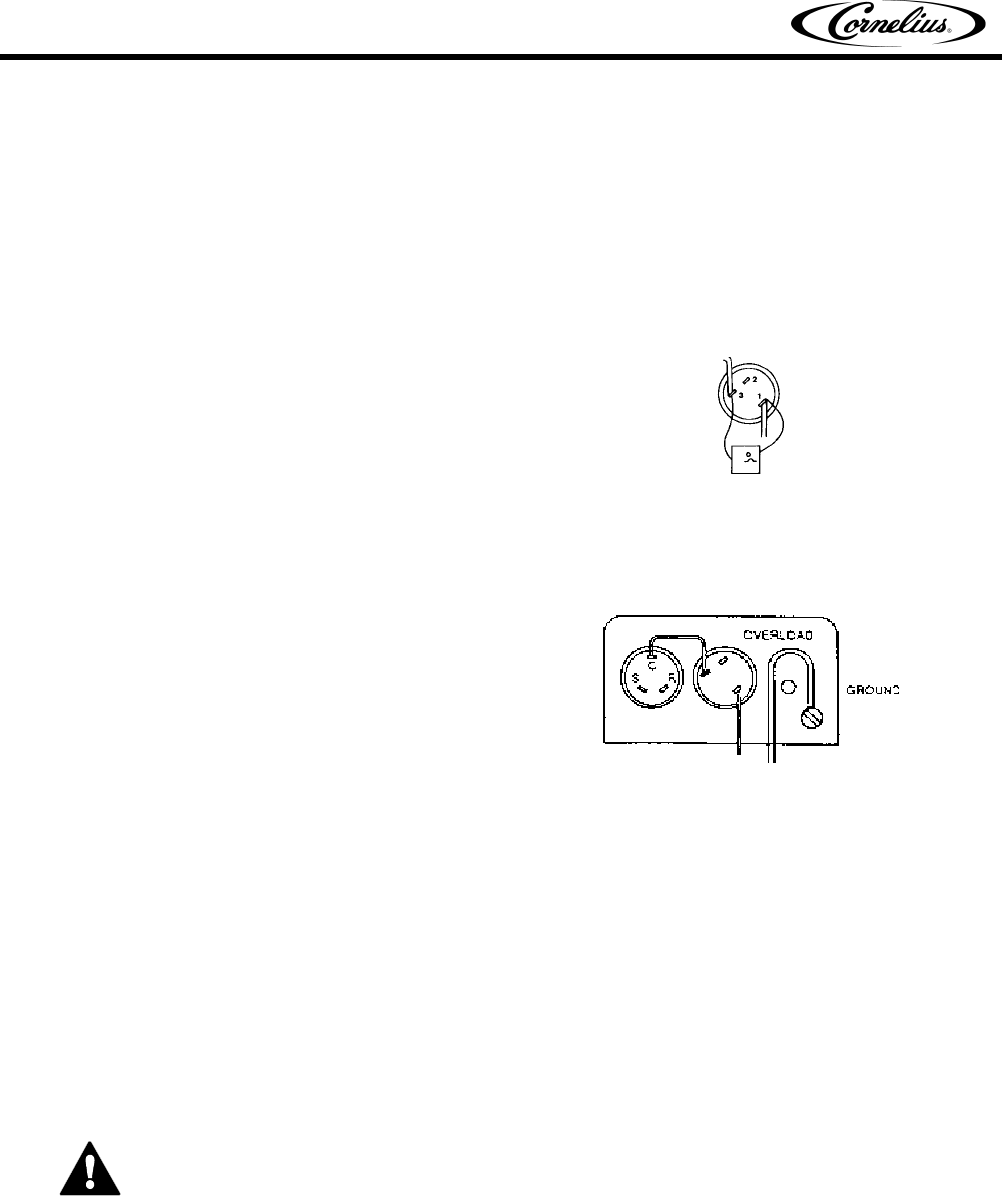

Using a volt–ohmmeter check the continuity

across the overload, contact #1 and #3. If none,

wait for unit to cool down and try again. If still no

continuity, the overload protector is defective

and should be replaced.

FIGURE 9. OVERLOAD CHECK

The resistance readings on the windings will be

between 0.25 to 10.00 ohms, a meter capable of

these low readings must be used.

1. Check between “C” and “R.” Replace the

compressor if there is no continuity as the

run windings are open.

2. Check between “C” and “S.” Replace the

compressor if there is no continuity as the

start windings are open.

FIGURE 10. COMPRESSOR CHECK

3. Check between “C” and “R” or “S” and the shell of the compressor. If there is continuity, replace the

compressor as the motor is grounded.

4. Check between screw terminal on the overload and “C” on the compressor. Check and repair the

lead or connections if there is no continuity.

1. Check or replace start capacitor, disconnect bleed resistor before checking for shorted capacitor.

2. Check or replace run capacitor (if supplied) check for shorted capacitor or either terminal grounded

to case.