8

Converting Appliance For Use

With LP Gas

Propane conversion is to be performed by a JENN-AIR

AUTHORIZED SERVICER (or other qualified agency) in

accordance with the manufacturer’s instructions and all

codes and requirements of the authority having

jurisdiction. Failure to follow i nstructions could result in

serious injury or property damage. The qualified agency

performing this work assumes responsibility for this

conversion.

Electrical power and gas must b e turned of f

prior to conversion.

This appliance was adjusted at the factory for use with

natural gas. To convert it for use with LP gas (propane or

butane), each of the following modifications must be

performed: (A, B, and C)

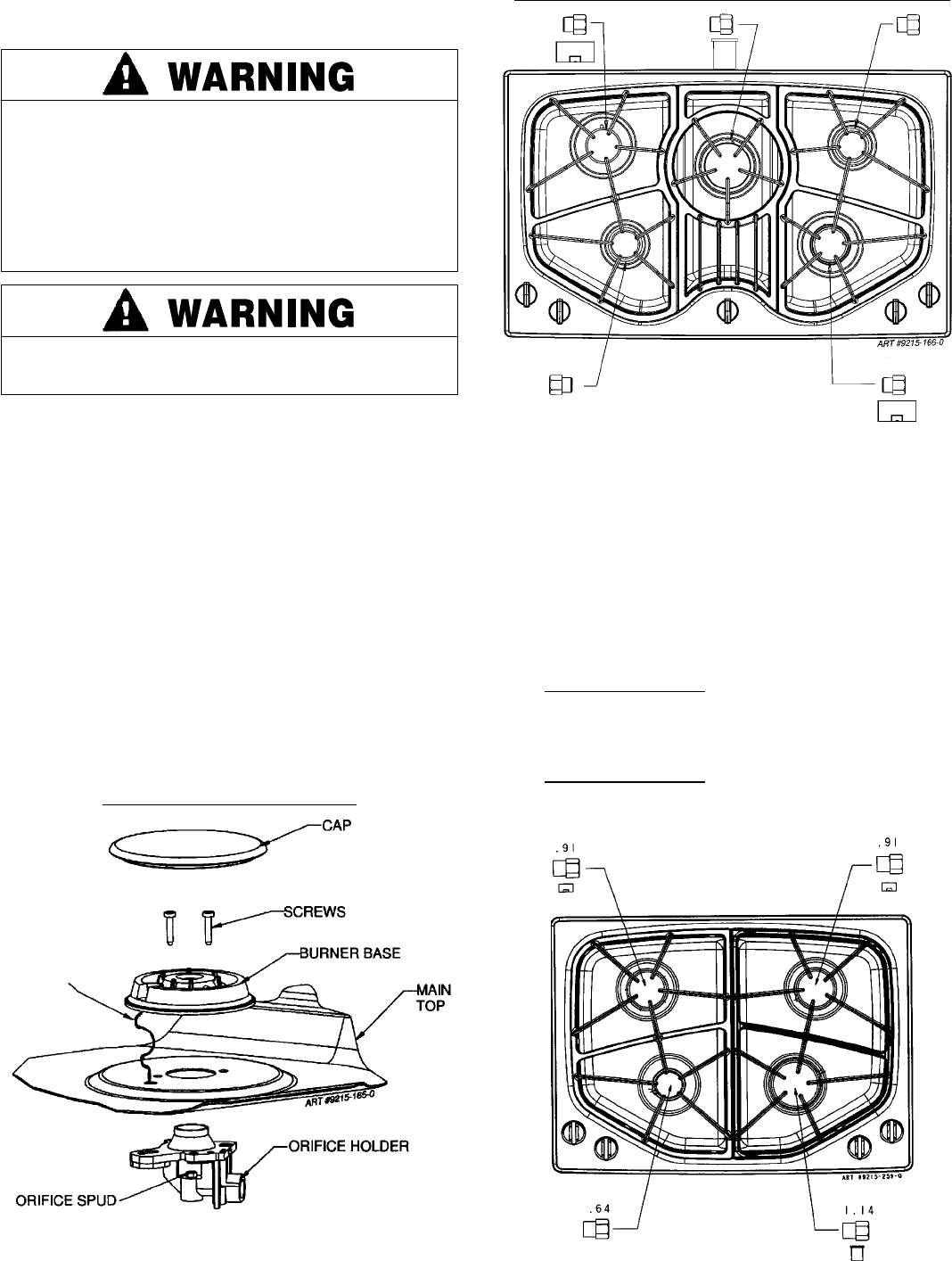

A. REPLACE ALL ORIFICE SPUDS

Step 1: Remove the grates and burner caps.

Step 2: Remove burner base by removing 2 (T-15)

6-lobe screws. (See figure 7). Leave spark wire

attached to base.

Step 3: Firmly press 9/32² (or 7mm) nut driver over

the orifice spud (figure 7) and loosen spud by turning

counterclockwise. Carefully lift nut driver out of burner

throat. Orifice spud should be captured in the recess.

Repeat this step for each burner.

FIGURE 7

REMOVAL OF ORIFICE

SPUD

SPARK WIRE

FIGURE 8

INSTALLATION OF LP ORIFICE SPUDS & CHOKES

.91 1.14

.64

.97

.64

Step 4: Locate the LP orifice spud packet included in

the literature packet. The spuds have small numbers

stamped on the side. This number codes the orifice

diameter and its correct burner location. Figures 8 and

9 show the correct LP orifice spud location. There will

be extra spuds that are not required for the JGC8430

installation.

Step 5: Carefully install the orifice spud in the

appropriate burner throat by turning clockwise to

tighten. Tighten to a torque of 15 to 20 inch-lbs.

Step 6:

JGC8430 - 30

²

²²

² Unit - Place 9.1k/10.5k burner

choke(s) into right rear and left rear (see figure 9)

orifice holder with chamfer facing down (see figure

10).

JGC8536 - 36

²

²²

² Unit - Place 9.1k/10.5k burner

choke(s) into right front and left rear orifice holder

with chamfer facing down (see figure 10).

FIGURE 9