Electrical

requirements

Venting

requirements

Electrical ground is required on this

appliance.

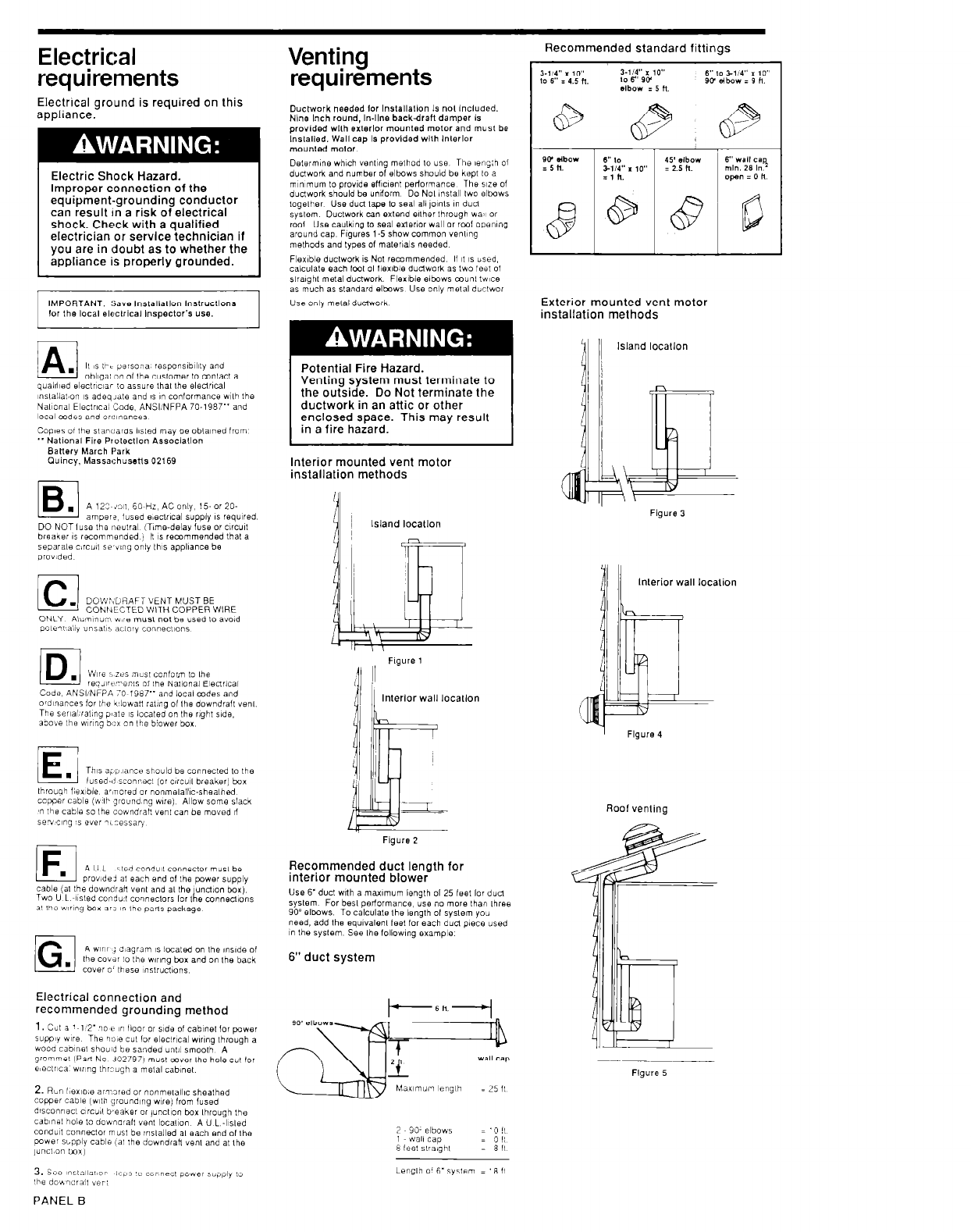

Recommended standard fittings

Ouchvork needed lor lnslallallon Is nol Included.

Nine Inch round, In-line backdraft damper Is

provided wllh exlerlor mounted motor and must be

Inslalled. Wall cap Is provided wllh lnlerlor

mounled motor.

Delermine which venl~ng melhod lo usa Thu leng:h 01

duclwork and number of elbows should be kept 10 a

mmmum lo provide efllcent perlormance The we of

duclwork should be undorm Do Nol inslall Iwo elbows

loqelher Use dud lake lo seal all ,o1n1s or. duel

Electric Shock Hazard.

Improper connection of the

equipment-grounding conductor

can result In a risk of electrical

shock. Check with a qualified

electrician or service technician if

you are in doubt as to whether the

appliance is properly grounded.

sykm Ductwork can extend elth& through wa’~ or

rod Use caulking to seal exierior wall or rcrot open\ng

around cap FIguris l-5 show common wwng

melhods and types of

malerials

needed

Flexible ductwork 1s Not recommended If I( 1s used,

calculale each fool 01 llexlble dudwork as Lwo feet of

slralghl metal ductwork. Flerlble elbows c~unl twce

as much as slandard elbows Use only melal dbclwor

Use onlv melal ductwork

IMPORTANT: !;a,. lnstallallon lnsirucllons

Exterior mounted vent motor

installation methods

11 II

Island locallon

Potential Fire Hazard.

Venting system must terminate to

the outside. Do Not terminate the

ductwork in an attic or other

enclosed space. This may result

in a fire hazard.

Interior mounted vent motor

installation methods

Island locallon

Figure 3

~nslallat~on IS adoq~ate and 1s in conformance wllh the

Nal~onal Eleclrlca, ‘Code. ANSIINFPA 70-1987” and

local mdes and or~!,nances

BaHery March Park

Cluincy, Massachussns 02169

IB

.

A 123 in,, 60 Hz, AC only, 15. or 20.

amper?. iused evxlr1c.3 supply 1s required.

DO NOT IUSB the ~leutral (Time-delay fuse or c1rcu0

breaker 1s recommended, II IS recommended thal a

separale c,rcui, se’v,ng oniy ,h,s appliance be

prov,ded

/c1

. DOW:;bHAFT VENT MUST BE

CONNECTED WITH COPPER WIRE

Code, ANSI/NFPA 70 ,987” and local codes and

o’dlwrces for Ihe k’lowa!, ral,ng 01 Ihe downdrall ye,,,.

The ser~al~ral~no o,aIe 1s located on Ihe riaht side.

lnlerior wall location

1

Flgure 4

1E

.

This +i, lance should be connecled lo the

lused-i! sconrecl (or circu,, breaker] box

Ibroug’l f;ex~ble, ar,nored or nonmelalllc-shealhed.

ccpper cable (wlb grouna ng we) Allow some slack

T Ihs cable so Ihe cowndrah vent can be moved II

sevclng is e”el nL:essar,

Roof venling

Figure 2

1F

A U L

.

ited cond”,, conneclor mus, be

prov,de> al each end 01 Ihs power supply

cable (al the downdran “en, and a, Ihe unct,on box)

Two U L ~+sled condu:! co,,,,eclors lor 1 e connenions

b

a’ I’le w~r,ng box ari in Ihe parls package

Recommended duct length for

interior mounted blower

Use 6’duct with a maximum lenglh 01 25 feet lo, dud

syslem For besl perlormance, use no more lhan three

90’ elbows. To calculale Ihe length 01 syslem you

need, add the eqwalenl Ieel for each duel piece used

in Ihe syslem. See Ihe lollowlng example

6” duct system

/G

A WIIII j d,agram ,s located on Ihe ,ns,de of

.

Ihe co”dr lo Ihe w,r,ng box and on Ihe back

cover o’ these ~mslrucl~ons

Electrical connection and

recommended grounding method

2. Rbn I~BXID,~ armored or nonme,allIc sheathed

copper cable (wllh grounding we) from fused

dlsconnecl c,rcu~l b,eaker or ,uncl,on box lhrauqh Ihe

cabInsI hole lo dounarall “en, local~on

A U L &led

cond”,t conr,eclor musl be ;nslalled a, each end of Ihe

cower supply cable ,a, :he downdraH venl and a, Ihe

,unc,.on tmxj

Figure 5

2 90. elbows

1 wali cap

8 !eel slra,gh,

Length o’ 6’syslem = ‘8 ,I

PANEL

B