Low Profile – 1600-000-A Advantage Series Service Manual – Domestic

3

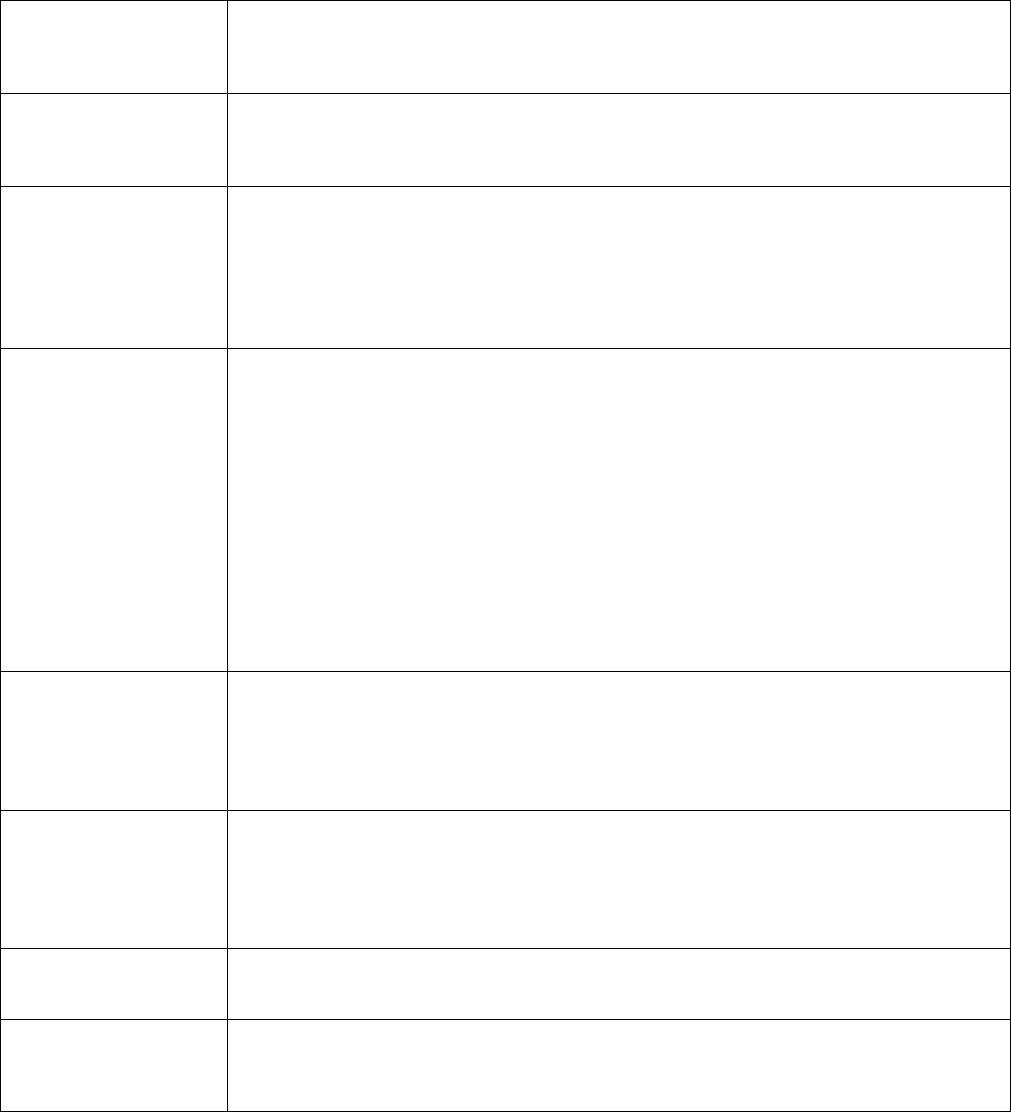

SEQUENCE OF OPERATIONS / 1600-000-A, 1601-000-A

MODEL 1600-000-A / 120 VAC / 60 HZ / NATURAL GAS

MODEL 1601-000-A / 120 VAC / 60 HZ / L.P. GAS

POWER SUPPLY Electrical power to be supplied to the oven by a three conductor cordset. Voltage from

the black conductor to the white conductor to be 120 VAC.

White conductor is Neutral.

Green conductor is Ground.

CONTROL BOX

AUTO COOL DOWN

When the temperature in either one of the Control Boxes reaches 120°F ± 3°F (49°C

± 1.7°C), the Cooling Fan Thermostats will switch power to the Cooling Fans. The

thermostats will interrupt power to the Cooling Fans when the temperature falls to

100°F ± 3°F (37°C ± 1.7°C).

MAIN FAN CIRCUIT 120 VAC is permanently supplied to the normally open double pole power switch, a

normally open contact of the oven power relay and the normally open cooling fan

thermostats. Closing the power switch supplies 120 VAC, through the 3 A cooling fan

fuse, through both control box hi-limit thermostats to the coil of the oven power relay.

These normally open contacts now close supplying 120 VAC, through the 10A main

fan fuse to the 2 main fan motors and the 2 burner motors. Power is also supplied to

the cooling fans, the heat and conveyor control systems.

BURNER CIRCUIT Closing the Oven Power Relay supplies 120 VAC to the (2) burner Systems

NOTE: This oven utilizes (2) complete Burner/Temp. Control systems. The sequence

of operations is the same for each system.120 VAC is supplied, through the

Centrifugal Switch of the Main Fan Motor (this switch closes when the Main Fan

reaches approximately 1600 R.P.M.) through the 10 Amp Fuse, to the Ignition

Control, the Electronic Temperature Control, and the burner transformer. As the

Burner Blower reaches approximately 1600 R.P.M., its internal centrifugal switch will

close, supplying 24 VAC to the ignition control. The Ignition Control operates on both

24 VAC and 120 VAC. When the control is energized by 24 VAC, 120 VAC is

switched to the Hot Surface Igniter for 45 seconds for Hot Surface Igniter warm up.

The igniter glows red, 24 VAC is switched to the gas valve which opens, and ignition

should now occur. If ignition does not occur in 6 seconds, the control will lock out. To

recycle after lockout, turn off the burner switch for 45 seconds and then turn the

switch back on.

TEMPERATURE

CONTROL

When the Centrifugal Switch of the Main Fan Motor closes, power is applied to the

Temperature Control. The1K ohm Temperature Pot is adjusted to desired

temperature. Thermocouple will provide varying millivolts to the Temperature

Controller. The Temperature Controller supplies 120 VAC to the solenoid valve at

intermittent intervals to maintain desired temperature. The heat lamp is energized

with the solenoid valve.

CONVEYOR DRIVE Closing the on/off switch supplies 120 VAC through the oven power relay to the motor

control board. AC volts are converted to DC volts and are supplied to the conveyor

motor at terminals A+ and A-.Adjustments of the speed control potentiometer will

change resistance at terminals P1 and P2 varying the DC voltage to the motor. The

speed of the conveyor motor will increase or decrease as the DC voltage from the

board increases or decreases respectively.

NOTE: The conveyor control uses a sensor and magnet, mounted on the conveyor motor that

senses the motor speed. Any change in motor load, (±RPM) is detected by the

sensor and the voltage to the motor is adjusted accordingly.

TEMPERATURE

DISPLAY

Closing the switch supplies 120 VAC to the primary of the temperature display

transformer. The secondary of this transformer supplies 12 VAC to the temperature

display. The thermocouple supplies D.C. millivolts to the temperature display. The

display converts this millivolt reading to a temperature reading.