8

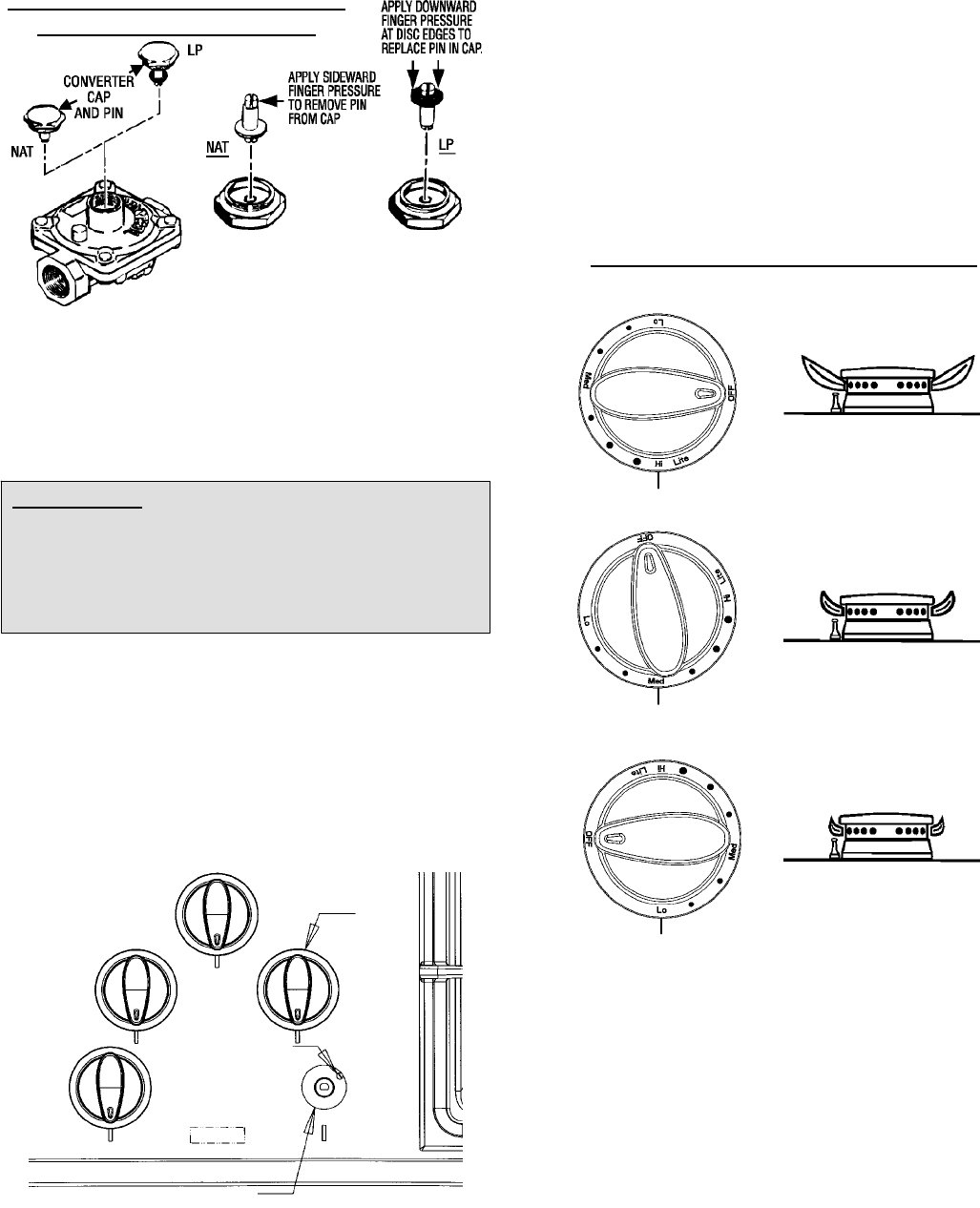

B. INVERT CAP IN APPLIANCE PRESSURE

REGULATOR (See figure 10)

With the appliance installed, the appliance regulator

should be located as shown in figures 3 o r 4.

FIGURE 10

CONVERSION OF APPLIANCE

PRESSURE REGULATOR

C. LOW FLAME ADJUSTMENT (See figure 11)

This appliance is shipped from the factory with low and

high flame settings adjusted for use with natural gas.

To set for use with LP proceed as follows:

1. Remove control knob from valve stem.

CAUTION: NEVER USE A METAL BLADE TO

PRY KNOB OFF. IF KNOB CANNOT BE EASILY

REMOVED, TUCK THE FOLDS OF A CLOTH

DISHTOWEL UNDER THE KNOB AND PULL THE

TOWEL UPWARD WITH STEADY, EVEN PRES-

SURE.

2. Carefully remove rubber grommet.

3. Locate the valve adjustment screw . See figure 11.

4. Insert a slender, thin-blade screwdriver into knob

hole and engage blade with slot in adjusting screw.

5. Turn the adjusting s crew clockwise until tight (5-7

in-lbs max.). Do not over tighten.

6. Replace rubber grommet and control knob.

7. Repeat for remaining burners.

FIGURE 11

KNOB

ADJUSTMENT

SCREW

KNOB HOLE

(KNOB AND GROMMET REMOVED)

After adjusting the screw the burner should produce a

stable, steady blue flame of minimum size. The setting

should be checked by turning knob from high to low

several times without extinguishing the flame.

This operation will automatically provide the proper flame

size at medium setting.

After C onversion Steps A, B and C have been completed,

check the appearance of each burner flame at the Hi and

Lo settings against figure 12. If the flames appear too

large or too small, review each step to make sure it w as

completed correctly.

FIGURE 12

FLAME APPEARANCE AT HI AND LO

Reviewed by Stewart, Steven | Released