100646 PUBLICATION DATE Sep 05 INSTALLATION AND MAINTENANCE MANUAL 17

AIR VENT CONNECTION

WARNING!

WATCH OUT, VAPOURS ESCAPE FROM THE MACHINE THROUGH THE AIR VENT OPENING!

DO NOT COVER OR CONNECT TO ANYTHING!

On the backside, the washers are provided with an air vent opening of O.D. 75 mm / 3".

Do not cover the washer air vent opening. It is part of the back flow prevention water system. It also takes

care that the tub can not be pressurized by water intake and vapor of the hot water, this allows for proper

measuring of the water level.

For the safety of everyone make sure that unauthorized persons cannot reach the backside of the machine.

4.7. CONNECTION OF LIQUID WASHING SOAPS DOSING

It is possible to connect an external dosing of liquid soaps to the machine.

WARNING !

DISCONNECT THE MACHINE SUPPLY POWER INLET BEFORE INSTALLATION.

THE INLET TERMINALS ARE UNDER CURRENT EVEN WHEN THE MAIN SWITCH IS OFF

ELECTRICAL CONNECTION AND CONNECTING THE MACHINE INLETS MUST BE CARRIED OUT

BY AUTHORIZED WORKERS ACCORDING TO INSTALLATION MANUAL INSTRUCTIONS AND IN

ACCORDANCE WITH VALID LOCAL STANDARDS.

AFTER THE HOSES ARE CONNECTED PUT ALL MACHINE COVERS BACK TO THEIR PLACES.

For connecting the liquid soap inlets and wiring for machines 6kg / 13lb, 7kg / 16lb, 10kg / 22lb you must take

of the top panel. Unscrew the two bolts and take the top panel of the machine. For 16kg / 36lb machine it is

sufficient to open the top panel by means of the two key switches at the front.

At the right side panel there is a support for the top panel.

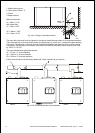

The hoses of external dosing of liquid soaps are

pushed through the holes in the rear panel after

removing the plugs. The hoses should be protected

by rubber bushings where penetrating the rear panel.

After this make as many holes in the soap hopper,

fig. 4.7.A, pos.1) as you have liquid soap hoses.

Connect the hoses to the soap hopper by means

of clamps.

Fig 4.7.A. Connection soap hopper

WARNING !

CHECK IF THE HOSES ARE TIGHTEN BY THE CLAMPS !

ANY LEAKAGE OF CHEMICALS MAY CAUSE CORROSION ON THE PARTS IN THE MACHINE.

The liquid soap pump system supply needs to be connected to an external electrical source. Only authorized

workers with a valid qualification must execute the electrical connection of the machine according to the valid

local standards. Do not connect the pump system in the machine. The liquid soap signals are available

in the machine on a connector, see fig. 4.7.B. The first terminal is the common line of the signals. The following

terminals are the signals that will be active depending of the programmed wash program. These signals have

a potential of max. 250V. Use a cable that is sufficient for their function and pass it in the appropriate opening

in the machine. Connect these signal terminals like the manufacturer of the liquid soap system requires.

The liquid soap system may draw maximum 0,1A out the control circuit of the washer-extractor.

!

!

!