16

SECTION 2

INSTALLATION

=

G. Maintenance

It is recommended to check yearly the minimum and the

maximumsettingandreadjustthemifnecessary.

H. Connection

WARNING

Some procedures in this section may require

conversions, readjustments, or service on the

oven's gas system. Before performing these

procedures, check that the main gas supply valve and

the circuit breaker/fused disconnect are in the OFF ("O")

position. After completing these procedures, perform a

gas leak test before operating the oven.

CAUTION

The terms of the oven's warranty require all start-ups, con-

versions and service work to be performed by a Middleby

Marshall Authorized Service Agent. The installation, start-up

and changes required when changing from one gas type to

another can be performed ONLY by a certied professional.

NOTE: Certainsafetycoderequirementsexistfortheinstallation

of gas ovens; refer to the beginning of Section 2 for a list of

theinstallationstandards.Inaddition:

• In the USA, the installation must conform with local codes,

or in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1.

• In Canada, the installation must conform with local codes,

or in the absence of local codes, with the Natural Gas

Installation Code, CAN/CGA-B 149.1, or the Propane

Installation Code, CAN/CGA-B 149.2, as applicable.

• In Australia, the installation must conform with AGA Codes

AG311 andAG601, andwith any requirementsof the

appropriate statutory authority.

• In CE countries, the gas supply connection should be

according to EN-203 (gas appliance directive) and to

applicable ISO 228-1 or ISO 7-1 recommendations. All

aspects of the gas supply connection must comply with

current IEC/CEE requirements and with allapplicable

local, national, and international codes.

• For all ovens equipped with casters, the gas line connection

shallbemadewith:

- A connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69

(in USA), or Connectors for Movable Gas Appliances,

CAN/CGA-6.16 (in Canada).

Checktheoven’sgassupplyrequirementstodeterminethe

typeofgastobeusedwiththeoven.Ifthegastyperequired

doesNOTmatchthelocalsupply:

• For North American installations, a conversion kit is

supplied with the oven to allow operation using propane

gas. Refer to Part B, Gas Conversion, in this section.

• ForCEovens,directionsforconvertingtheovenforuse

with other gases are described in Part D.1, Preparation

for Use with Various Gases, in this section.

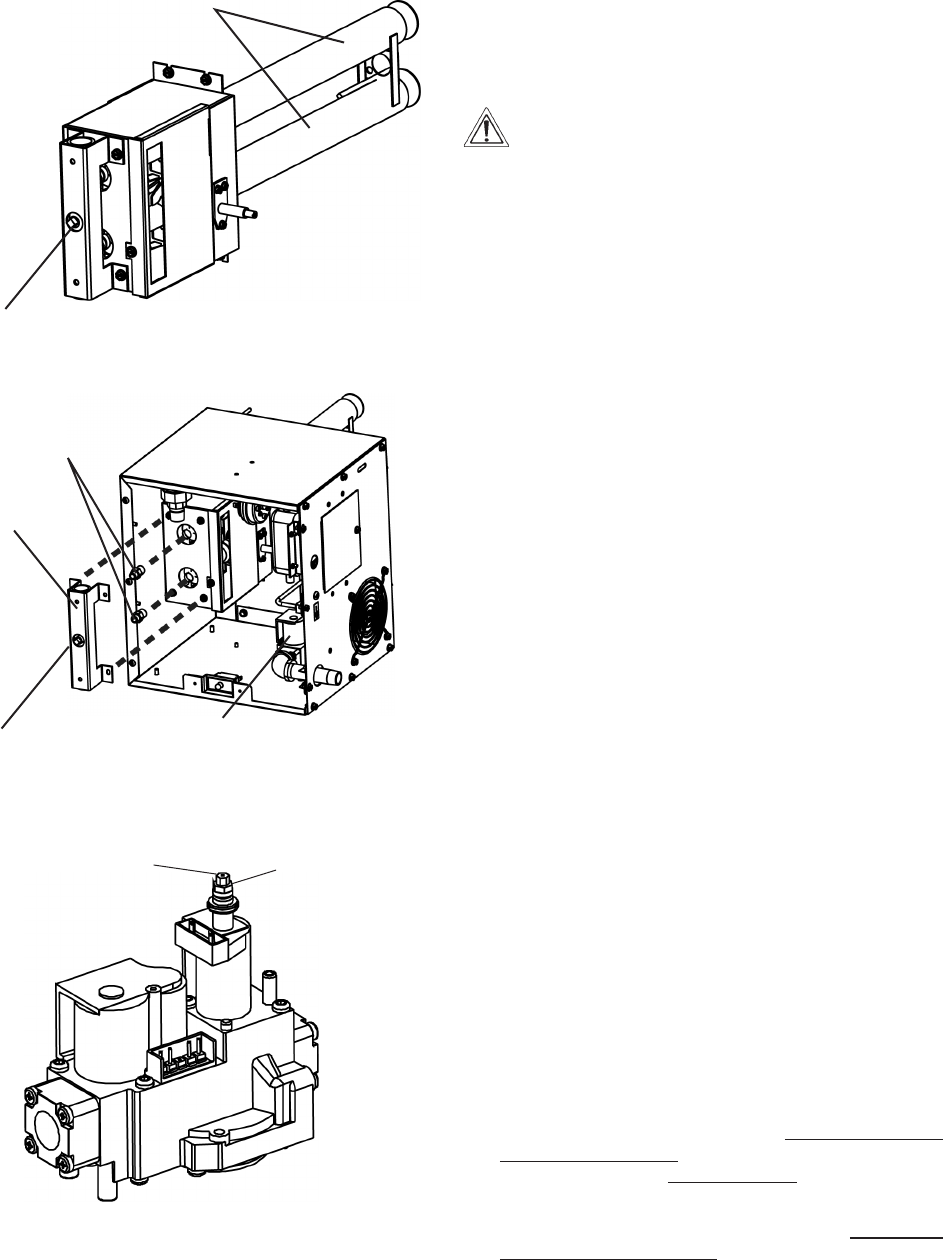

Figure 2-16. Gas Burner Assembly

Figure 2-17. Burner Assembly

Figure 2-18. Gas Valve

F. Checkout

After any adjustment, set appliance in operation and observe

through a component cycle to ensure that burner system

components function correctly.

Gas Burner

Manifold Pressure Tap

Manifold Pressure Tap

Gas Valve

Gas Burner

Assembly

MainOrices

Adjustment Screw (5 mm)

for minimum pressure

setting

Adjustment

Screw (8 mm) for

maximum

pressure

setting