SECTION 4

MAINTENANCE

43

E. Blower Fan Shaft Bearing Lubrication

CAUTION

Over-greasing damages the bearing seals and

accelerates grease loss, which shortens bearing

life. Wipe off any excess grease on and around

the bearing. Reinstall the rear shroud to allow the

oven to operate

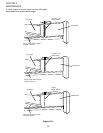

Grease the two (2) main blower fan shaft bearings (Figure

4-43), using a special grease (MM P/N 17110-0015 lithium-

base, high-temperature grease). ONLY ONE STROKE of

a grease gun is required for each bearing.

Figure 4-43.

Upon completing the fan belt check (or replacement) and

the bearing lubrication, reinstall the rear shroud, fastening

it with six screws of the rear shroud.

F. Split-belt Conveyor Shaft Cleaning

It is very important that the split-belt conveyor drive and

idler shafts are removed from the conveyor frame for

cleaning and lubrication.

CAUTION

Use a turbine oil or light machine oil. DO NOT

USE WD40 or similar product. These oils

evaporate and cause the shafts to seize.

1. Perform the conveyor removal steps described in

Monthly Maintenance, paragraph “A”. After the conveyor

is removed, lay it on a flat surface.

2. Remove the two conveyor belts by disassembling the

conveyor master links, as described in Monthly Mainte-

nance, paragraph “H”. Then, remove the two conveyor

belts by rolling them up.

3. Remove the conveyor adjustment bolts to allow the

idler brackets to swing free.

Figure 4-44.

4. Drop the idler shaft assembly clear of the frame through

the front frame slot.

Figure 4-45.

5. Pull the front and rear shafts apart and apply oil to both

the extended shaft and the interior of the hollow shaft.

Using a rag, wipe oil off parts. Repeat until shafts are

clean. Apply more oil to shafts then reassemble.

Figure 4-46.