13

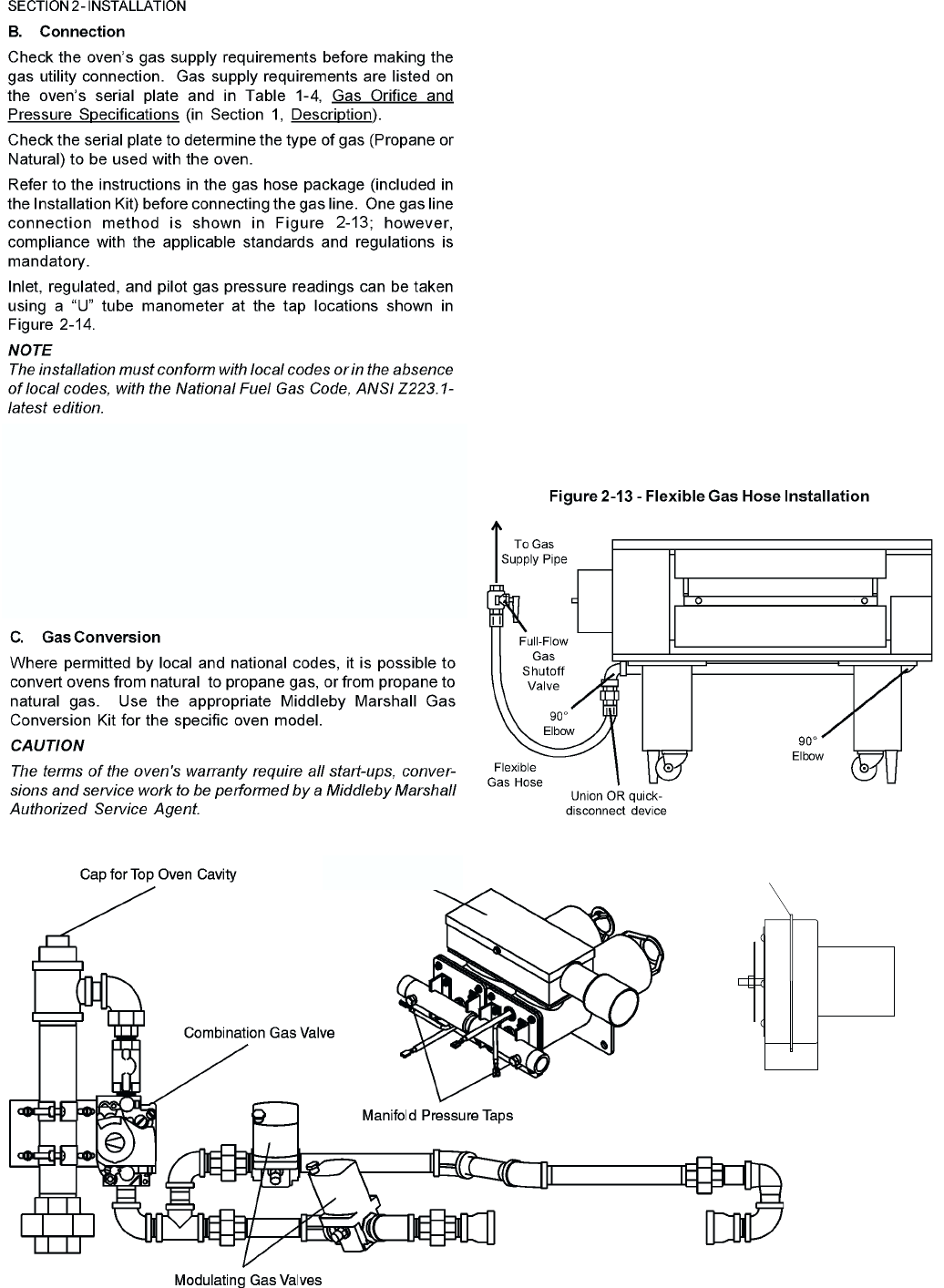

Certain safety code requirements exist for the installation of

gas ovens; refer to the beginning of Section 2 for a list of the

installation standards. In addition, because a the oven is

equipped with casters, the gas line connection shall be made

with a connector that complies with the Standard for Connec-

tors for Movable Gas Appliances, ANSI Z21.69 (in U.S.A.), as

well as a quick-disconnect device that complies with the

Standard for Quick-Disconnect Devices for Use With Gas Fuel,

ANSI Z21.41 (in U.S.A.).

D. PS870 Propane conversion

Four items have to be changed, to change the oven to LP:

1. Adjust internal burner air shutters.

2. Replace main Orifices

3. Replace (and adjust) the spring in the main valve (see LP kit)

4. Adjust modulating valve bypass settings.

Disconnect the manifold unions closest to the main burner,

and remove the manifold assemblies (four screws each).

Remove the addition four screws holding the burner cores and

slide out each burner core (leaving the ignition and sense

wires connected). Adjust the internal air shutters fully open,

and replace the cores.

Replace the main orifices on the manifold assemblies with the

LP units, and replace the manifold assemblies. Reconnect the

unions. Replace the valve spring with the LP spring, and adjust

the downstream pressure to get 7″ WC.

Adjust the bypass screws in the side of each modulating valve

to approximately 1/6 turn from fully closed. If this setting is too low,

the burners will shut off when trying to modulate. If it is too open,

the unit will tend to gradually raise up in temperature at standby.

Figure 2-14 - Gas Burner/Blower Motor and Piping Assembly

Gas Burner

Burner/Blower Motor