The minimum chimney draught requirement for the

200SFW at nominal total heat output is 2.5 Pa.

The minimum chimney draught requirement for the

212SFW at nominal total heat output is 12 Pa.

The mean flue gas temperature of the Rayburn

200SFW directly downstream of the flue spigot at

nominal heat output is 131ºC.

The mean flue gas temperature of the Rayburn

212SFW directly downstream of the flue spigot at

nominal heat output is 210ºC.

The appliance is not suitable for installation in a shared

flue system

Checking Existing Chimney

The internal and external location of the chimney should

be checked before the appliance is installed and

rectification made where necessary to prevent leakage

or porosity. The soundness of the chimney which

should have a minimum flue dimension of 150mm can

be confirmed by smoke testing.

Advice on the test method can be obtained from

HETAS Ltd.

When repairing or re-using existing chimneys it is

recommended that the building control officer be

consulted before the commencement of work with

particular attention to the chimney height and its

termination

The chimney MUST be swept before installation.

Erecting New Chimney

The flue through the chimney should be formed with

pre-cast moisture and acid resistant liners with a

minimum internal diameter of 150mm diameter and all

in accordance with the current Building Regulations

(England and Wales) and in Scotland the Building

Standards (Scotland) (Consolidation) Regulations and

the Codes of Practice for chimneys and flues BS. 6461

Part 1 and BS. 7566 Parts 1 to 4.

Ensure the chimney liners are free of projecting internal

building jointing composition before the appliance is

installed.

Factory-Made Insulated Chimneys

It is recommended the chimney be ceramic lined and

comply with BS. 4543: Part 2.

The minimum diameter for a straight chimney is 150mm

and there should be not more than two bends of 45º

from vertical.

4

THE CHIMNEY

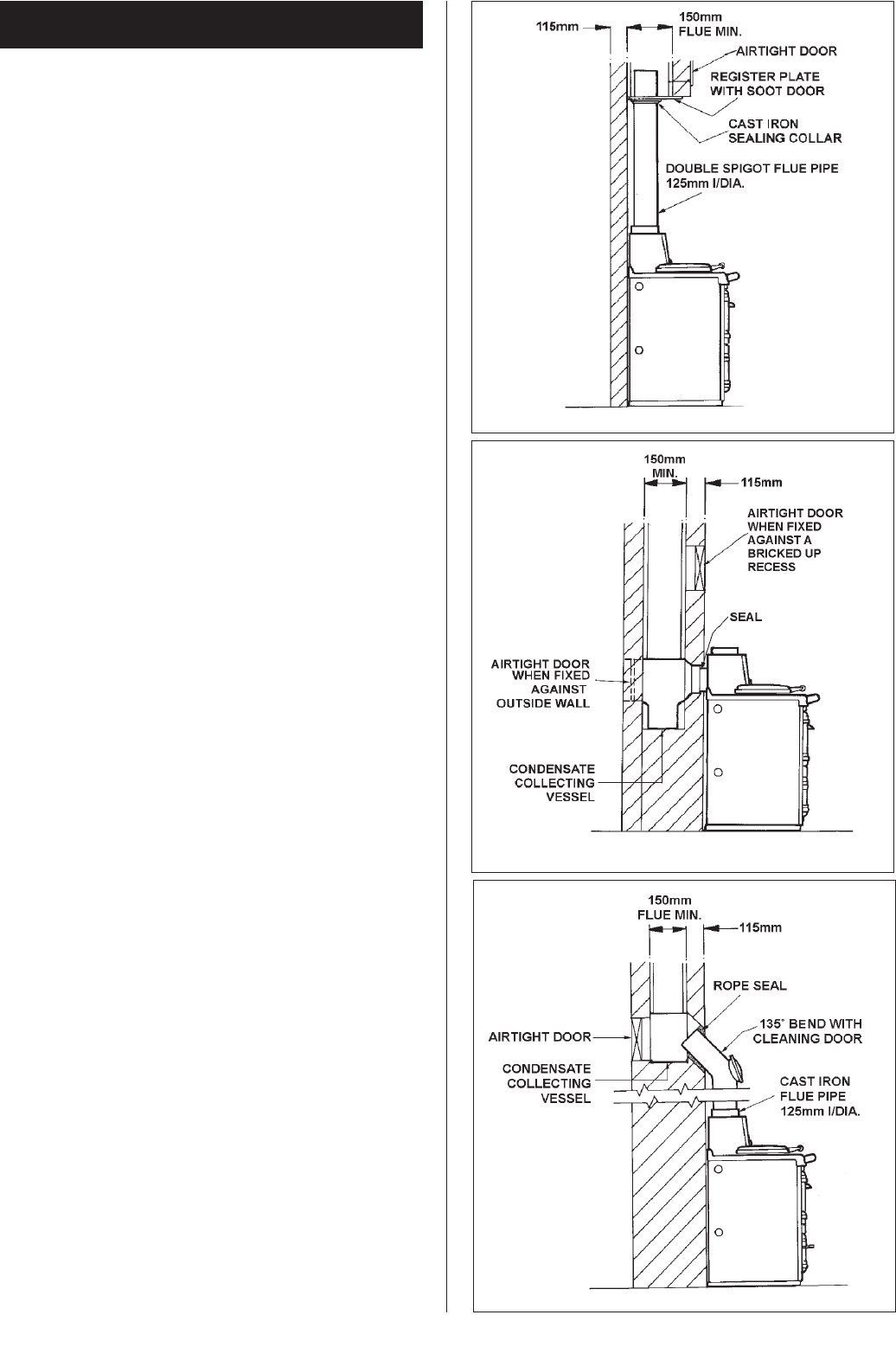

Fig. 2

Fig. 3

Fig. 4

DESN 510181 C

DESN 510182 C

DESN 510183 C