0$,17(1$1&($1'6(59,&,1*

GENERAL

A.

REMOVAL OF DEBRIS OR SOOT DEPOSITS;

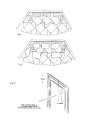

Allow the appliance to cool for one hour before removing all the coals and coal bed components for cleaning

purposes. Once all the components have been removed from the fire bed check that no debris has become lodged

in the burner ports (both front and rear). If any debris is present it may be easily removed with a thin piece of card

or similar to ease out any foreign matter. To ensure that the release of fibres from these RCF articles is kept to a

minimum, during installation and servicing we recommend that you use a HEPA filtered vacuum to remove any

dust and soot accumulated in and around the fire before and after working on the fire. When replacing these

articles we recommend that the replaced items are not broken up, but are sealed within heavy duty polythene

bags, clearly labelled as RCF waste. This is not classified as "hazardous waste" and may be disposed of at a

tipping site licensed for the disposal of industrial waste. Protective clothing is not required when handling these

articles, but we recommend you follow the normal hygiene rules of not smoking, eating or drinking in the work

area and always wash your hands before eating or drinking. Any soot deposits may be removed from either the

Thermocouple or Electrode tips with a soft cloth, do not use abrasive materials.

B. SERVICING COMPONENTS BELOW THE BURNER ASSEMBLY

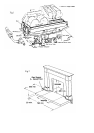

To remove trim, lift vertically to allow the formed tags in the rear of the trim to slide out of the notches in the

flanges of the box. (Assemble in the reverse sequence). Remove the coals, coal supports, burner inserts and front

simulated coal. To gain access to the components below the burner assembly it has to be removed from the Vent

Box by disconnecting the gas supply at the inlet elbow and unscrewing the two screws at the base of the fascia

panel. Where the supply is fed from the right hand side across the front of the appliance it will be necessary to

disconnect the supply from the isolation tap or restrictor elbow.

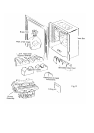

i) TO CLEAN OR REPLACE THE INJECTOR: Unscrew the compression nut connecting the gas supply to the

injector elbow while supporting the injector to prevent any distortion of the frame work. Unscrew and remove the

gas supply tube from the gas control valve, hold the injector lock nut with a spanner and rotate the injector.

Replace in the reverse order.

ii) TO REPLACE THE GAS CONTROL / FSD: Disconnect the three gas pipes and the thermocouple from the

gas control. Pull the control knob from the spindle, unscrew the lock nut securing the front of the control valve

(niting plate assembly), and remove the gas control valve. Replace in the reverse order.

iii) TO REPLACE THE PIEZO IGNITER: Pull the igniter lead from the piezo igniter tab. Hold the piezo lock nut

and rotate the piezo to unscrew and remove. Replace in the reverse order.

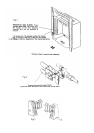

iv) TO REPLACE THE OXY-PILOT ASSEMBLY: The assembly is not an item that can be serviced as part of its

calibration depends on the proximity of the spark electrode and thermocouple tip. The assembly can be replaced

by removing the tube nut and the tube from the base of the pilot, the thermocouple from the FSD, the igniter lead

and the two M4 screws securing the bracket to the framework. Replace in reverse order, the spark gap is shown in

figure 12.

v) PROTECTIVE SIDE PLATES; These stainless steel plates are pushed over the flanges of the fibre retaining

channels and can be replaced if required.

Page 8