NME454, 654 & FME504, 804

January 2007

Page 31

REFRIGERATION SYSTEM SERVICE

General: This ice machine uses R-404A refrigerant

and polyolester oil. Do NOT use mineral oil in this

refrigeration system.

·

When the system is serviced, a special liquid

line drier is required. It is included with

replacement compressors.

·

R-404A is not compatible with mineral oil so

these ice machines use Polyolester oil.

Polyolester oil absorbs water very easily. A

system opened for service must be re-sealed as

soon as possible (15 minutes maximum).

·

Special leak detection equipment is required to

locate small refrigerant leaks. Usually a leak

detector capable of detecting a Halongenated

refrigerant or HFC-134a will work. Check with

the leak detector manufacturer if in doubt.

·

Evacuate to 300 microns.

·

Liquid charge the system

Access Valves: To use the

access valves:

·

Remove the cap from the

stem, use a 3/16" allen

wrench to check that the

valve is CLOSED. The

remove the core cap.

·

Close the valve and

replace the caps when

done. The valve must be

closed and the caps must be on or

the valve will

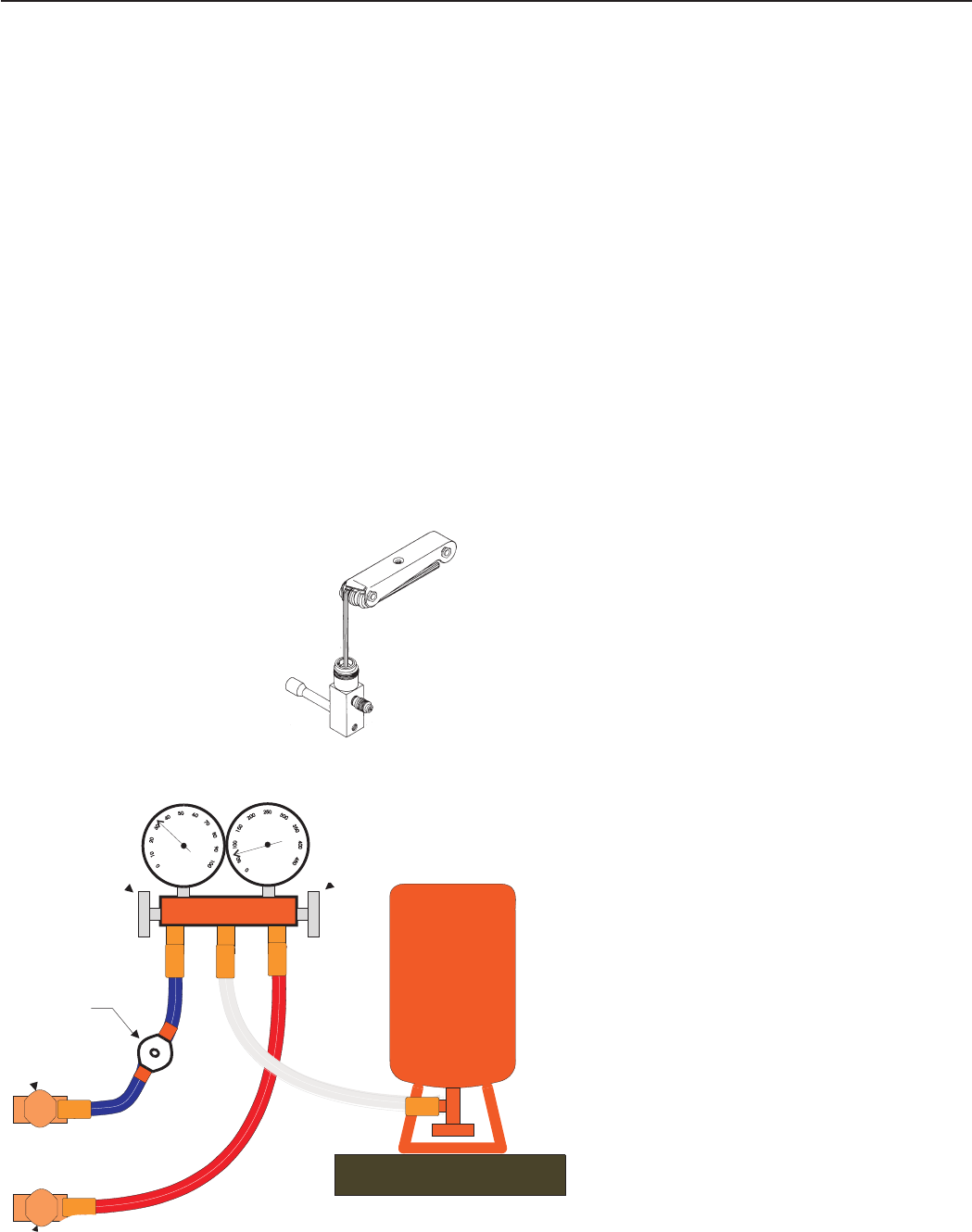

Instructions for Liquid Charging R-404A

In preparation for charging, the low side hose

should have a sight glass, and/or a restricting

device (such as a “Charge Faster”) installed in it

for metering liquid into the low side of the system.

1. After a thorough evacuation shut off the manifold

valves and switch off the vacuum pump.

2. Place a drum of R-404A onto an electronic

scale.

3. Attach the charging hose to the drum.

4. Open the valve on the drum and purge the

charging hose.

5. Zero out the scale.

6. Shut the low side access valve at the ice

machine.

7. Open the discharge manifold valve full open.

8. Watch the scale, when the correct charge is

shown, shut the manifold valve.

Note: If all of the charge will not “go in” the

discharge side:

A. Shut the discharge access valve at the ice

machine.

B. Switch the machine on.

C. Open the low side access valve at the ice

machine.

D. Open the low side manifold valve and observe

the sight glass to be certain that only gas is flowing

into the system.

E. When the proper charge is indicated on the

scale, shut off the manifold valve(s).

9. Shut off the valve on the refrigerant drum.

10. Re-open the manifold valves until all liquid has

flowed out of the hoses.

11. Shut the low side access valve on the ice

machine.

12. Remove hoses from ice machine and replace

all caps.

SCALE

Hose Connection Schematic for Liquid Charging

Sight Glass

R-404A

Tank Must

Be in Liquid

Dispensing

Position -

Check Tank!

Torque stem

to 6-8 ft.-lb.,

caps to 7-12

ft.-lb.