BJ5-615 Chapter 5: Maintenance 37 of 85

Replacing or Refilling Lubricant

• Fill the bearings uniformly with grease until all operating surfaces are well-greased.

• For the rotor bearings, a lubricant quantity of one third to a maximum of half of the

bearing volume per bearing is required. If too much grease is used, the lubricant will

become unusable due to excessive temperature.

• Only one type of grease may be used, mixing different types of grease is prohibited.

The bearings have been filled at the factory with lithium base saponification roller

bearing grease F3.

• Refer to the “List of Lubricants” in this section for recommended bearing grease.

Refilling lubricant

The grease reaches through the circulating grooves and bores via lubrication nipples into the

interior of the bearing.

The greasing quantity is .13 to .22 lbs (60 to 100 g) roller bearing grease F3 per bearing.

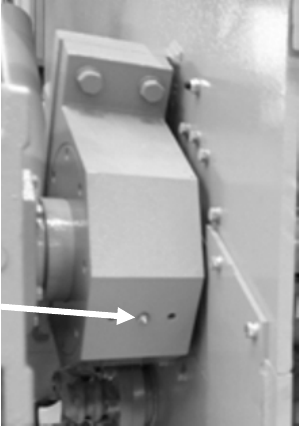

Grease Nipple

Replacing Lubricant

Renewing the lubricant between intervals is only necessary when there unusual noises or

overheating. Mounting and dismounting of the bearings must be carried out in

accordance with the instructions in this operation manual (see replacing the bearings).

1. Open the bearing.

2. Remove the bearing housing and the bearing cover.

3. Clean the bearing carefully using petroleum ether.

NOTE: Petroleum ether, petroleum, spirit, aqueous neutral or alkaline

cleaning agents may be used to clean the bearings. After washing