EJ5-615 Chapter 1: Safety 8 of 85

; ROTATION OF MOTORS: The correct rotating direction for the machine motor is

clearly marked on the machine. Always check for proper rotation of motors. Incorrect

rotation direction can cause severe damage.

; ELECTRICAL GROUNDING: All electrical equipment on the granulator must be

grounded in accordance to all local codes and Article 250 of the National Electric

Code.

; ALWAYS DISCONNECT AND LOCKOUT the main electrical power to the

granulator before performing any service.

; SAFETY INTERLOCKS MUST NOT BE BYPASSED. The mechanical and

electrical safety interlocks ensure the safety of personnel. They should never be

tampered with or removed for ANY reason. They should be checked frequently by a

qualified mechanic for proper operation.

; NEVER modify the machine configuration or any individual component without

written notice from the factory.

Remaining Risks

The machine is constructed so that you are able to operate it safely. Structurally non-

avoidable dangers are prevented as well as possible by the protective devices. Certain risks

still remain. It is imperative to be aware of these risks in order to avoid accidents. To avoid

danger, please observe all safety advice provided.

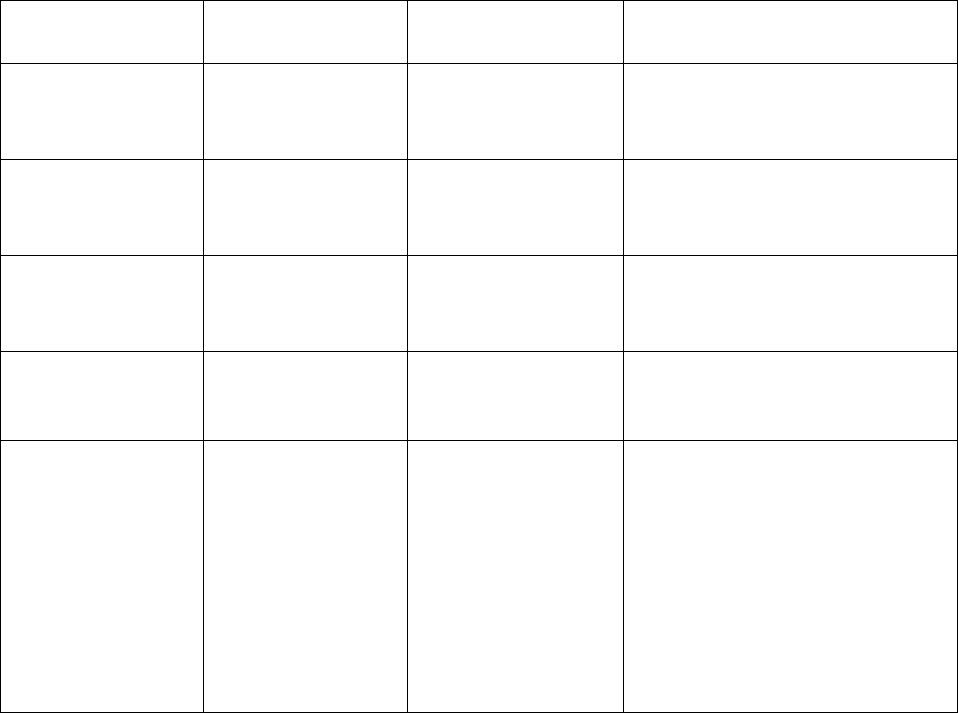

Type of Danger Activity Possible

Consequences

Preventative Measures

Danger of crushing by

heavy parts falling

down/over

Unloading and

transporting the

machine and/or

components

Serious injury

• Wear personal protective gear

• Follow safety instructions in

manual

Cutting caused by

sharp cutters—even

when rotor is

stationary

Cutter replacement,

cutter setting, cutter

sharpening and other

maintenance work

Serious injury

particularly to hands

and fingers

• Wear personal protective gear

• Follow safety instructions in

manual

Crushing when

opening/closing

maintenance doors on

front side of machine

Maintenance work Serious injury

• Make sure no persons are in the

danger area while closing the door

Tripping over cables

and other objects

All activities Serious injury

• Lay cables in accordance with

regulations.

• Keep work station clean and tidy.

Crushing, cutting,

amputation caused by

run down of the rotor

Maintenance work Serious injury or death

• Maintenance doors must always

be tightly locked during operation.

• DO NOT make the run down

safety devices ineffective by using

technical aids or other

manipulations.

• NEVER use hands to check if the

rotor has stopped.