Continuous Loss-in-Weight Blenders Chapter 3: Installation 29

3-6 Set-up

This section will discuss the mechanical setup and control system setup of the continuous

loss-in-weight blending system. After reading this section, you should be familiar with the

mechanical setup and the electronic control setup of the blending system.

Load Cell Adjustment

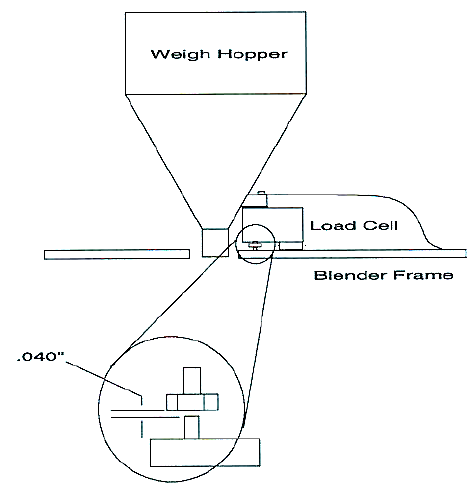

The mechanical setup of the continuous loss-in-weight blending system involves the

adjustment of the weigh hopper load cells (Please refer to the figure below). This figure

illustrates the proper adjustment of the load cell mechanical stop bolt. The setting for the

positive stop is necessary to prevent the load cell from being “over-ranged” by excessive

loading on the weigh hopper. The setting for the load cell stop is forty thousandths of an inch

maximum (.040”). This should be set by a feeler thickness gauge with the weigh hopper

empty.

If a feeler gauge is not available, the weigh hopper should be filled with the material that is to

be blended, and the stop adjusted so there is just a very small gap (a couple of sheets of

notebook paper) between the load cell, and the blender base stop. This will allow the load cell

to operate without mechanical restrictions and provide an overload safety. To adjust the stop,

adjust the screw located on the bottom of the load cell. Adjust the screw up to increase the

gap and down to decrease the gap.

Note: THE WEIGH HOPPER ASSEMBLY MUST BE FREE FROM FRICTION,

WITH NO MECHANICAL OBSTRUCTIONS OTHER THAN THE LOAD

CELL ITSELF.

Figure 10: Load Cell Mechanical Stop Adjustment