PRODUCT

OPERATION

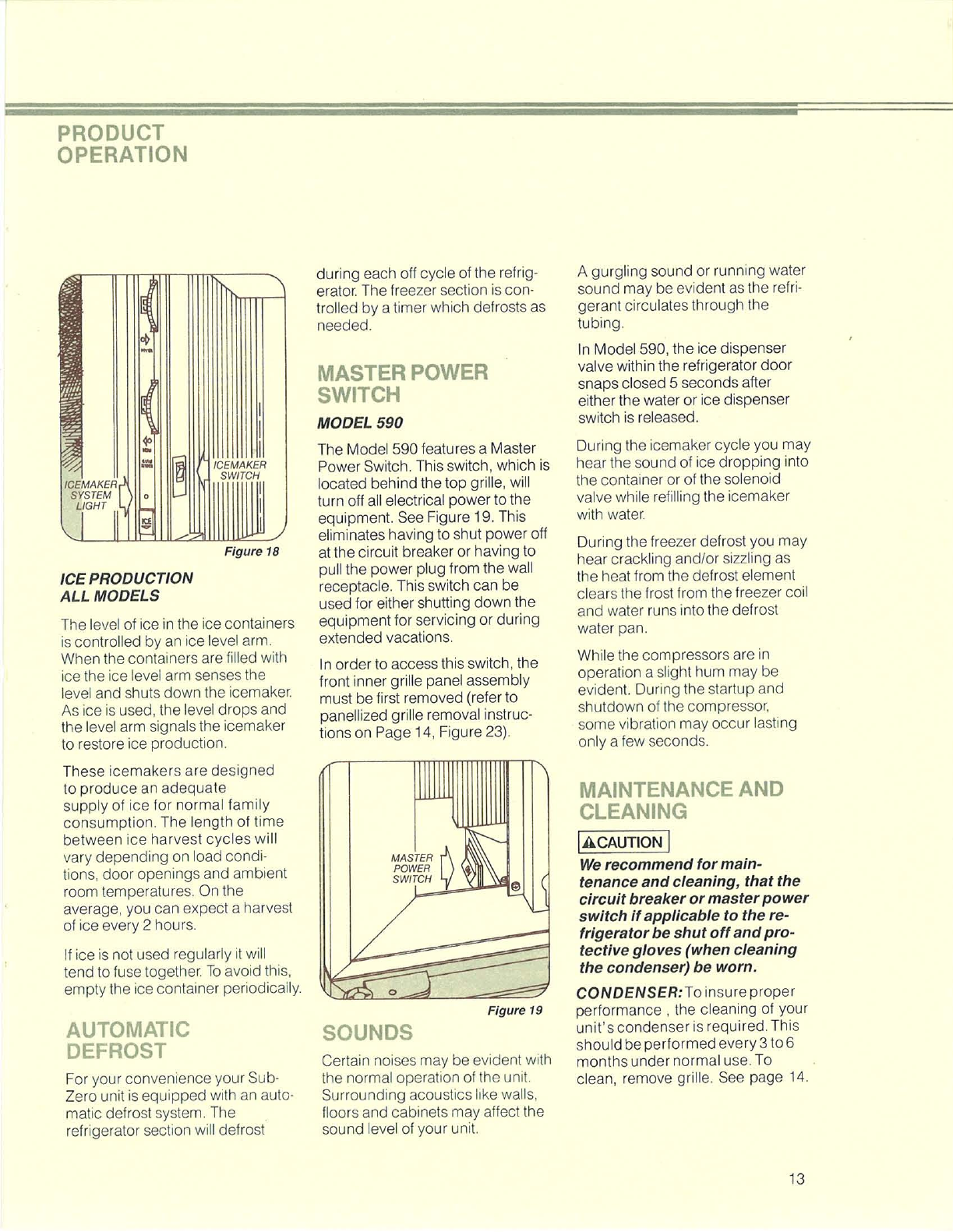

Figure 19

A gurgling sound or running water

sound may be evident as the refri-

gerant circulates through the

tubing.

In Model 590, the ice dispenser

valve within the refrigerator

door

snaps closed 5 seconds after

either the water or ice dispenser

switch is released.

During the icemaker cycle you

may

hear the sound of ice

dropping

into

the container or of the solenoid

valve while refilling the icemaker

with water.

During the freezer defrost you may

hear crackling and/or sizzling as

the heat from the defrost element

clears the frost from the freezer coil

and water runs into the defrost

water pan.

While the compressors are in

operation a slight

hum

may

be

evident. During the startup and

shutdown of the compressor,

some vibration may occur lasting

only a few seconds.

MAINTENANCE AND

CLEANING

!ACAUTION I

We

recommend for main-

tenance

and

cleaning, that the

circuit breaker

or

master

power

switch

if

applicable to the re-

frigerator

be

shut

off

and

pro-

tective gloves (when cleaning

the condenser) be worn.

CONDENSER:To

insure

proper

performance,

the cleaning of your

unit's

condenser

is required. This

should be

performed

every 3 to6

months

under normal use. To

clean, remove grille. See page

14.

MASTER

Q

POWER

SWITCH

~

SOUNDS

Certain noises may be evident with

the normal operation of the unit.

Surrounding acoustics like walls,

floors and cabinets may affect the

sound level of your unit.

MASTER POWER

SWITCH

MODEL 590

The Model 590 features a Master

Power Switch. This switch, which

is

located behind the top grille, will

turn off all electrical power to the

equipment. See Figure 19. This

eliminates having to shut power off

at the circuit breaker or having to

pull the power plug from the wall

receptacle. This switch

can

be

used for either shutting

down

the

equipment for servicing or during

extended vacations.

In

order to access this switch, the

front inner grille panel assembly

must be first removed (refer to

panellized grille removal instruc-

tions on Page 14, Figure 23).

during

each off cycle of the refrig-

erator. The freezer section is con-

trolled

by

a timer which defrosts as

needed.

I

t

I

I

::

~

ICEMAKER

SWITCH

0

I

I

g

I

Figure 18

For your convenience your Sub-

Zero unit

is

equipped

with an auto-

matic defrost system. The

refrigerator section will defrost

The level of ice in the ice containers

is

controlled by an ice level arm.

When the containers are filled with

ice the ice level arm senses the

level and shuts

down

the icemaker

As ice

is

used, the level

drops

and

the level arm signals the icemaker

to restore ice production.

These

icemakers

are designed

to

produce

an

adequate

supply of

ice

for normal family

consumption.

The length of time

between

ice

harvest

cycles

will

vary depending on load condi·

tions,

door

openings and ambient

room temperatures. On the

average, you can expect a harvest

of ice every 2 hours.

If

ice

is

not used regularly

it

will

tend to fuse together

To

avoid this,

empty the ice container periodically.

AUTOMATIC

DEFROST

ICE PRODUCTION

ALL

MODELS

13