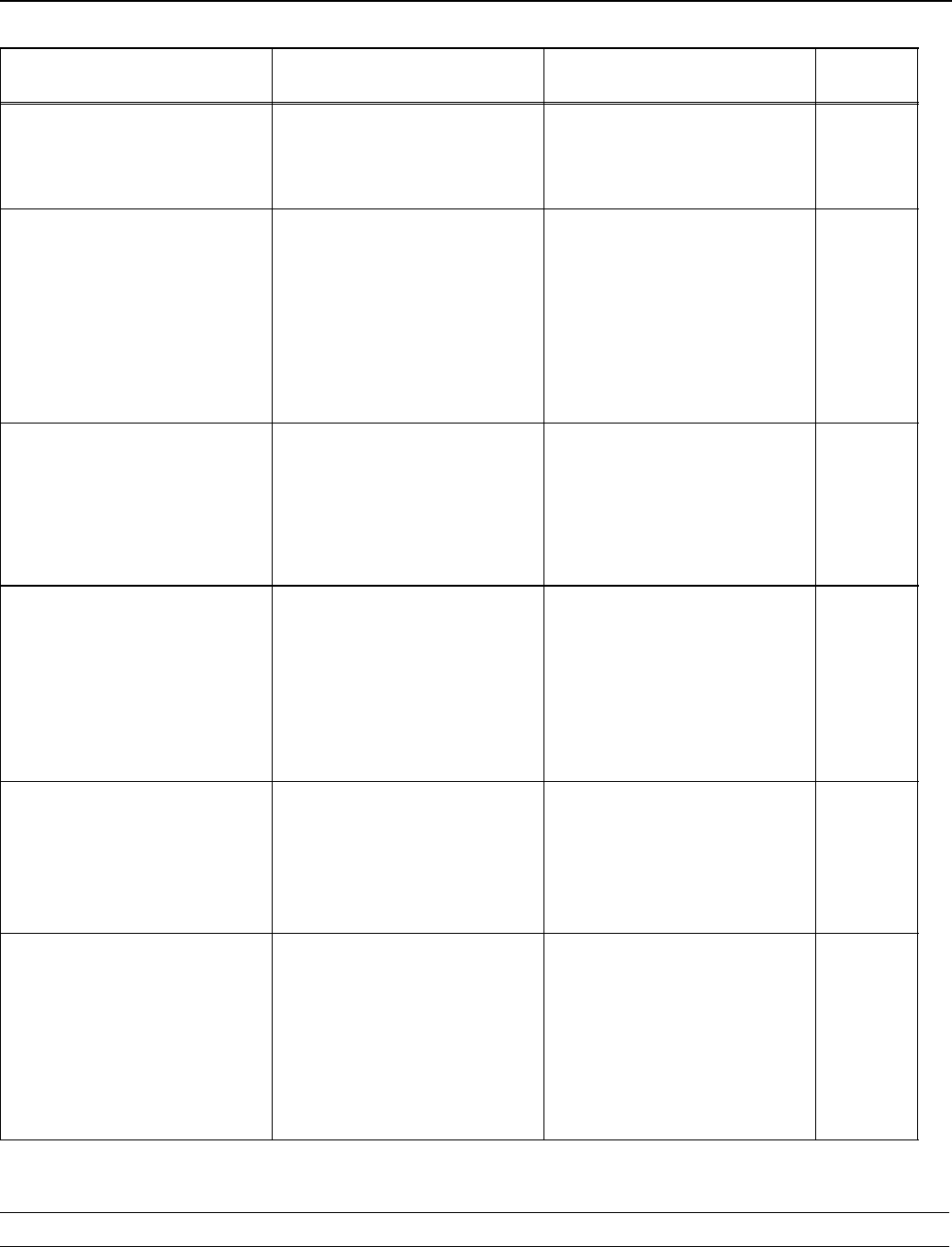

17

Model 390 Operating Procedures

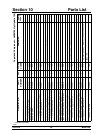

Section 8 Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY PAGE

REF.

1. No product being

dispensed with draw valve

opened.

a. Improper mixing of

product.

a. Carefully follow directions

for mixing product.

-- --

b. Mix low condition. b. Add mix to mix hopper. 9

2. Product too thin. a. Improper mixing of

product.

a. Carefully follow directions

for mixing product.

-- --

b. Missing, incorrectly

installed or bad scraper

blades.

b. Replace or install correctly. 10

c. Consistency control needs

adjusting.

c. Contact a service

technician.

-- --

3. Product too stiff. a. Consistency control knob

needs adjusting.

a. Contact a service

technician.

-- --

b. Improper mixing of

product.

b. Carefully follow directions

for mixing product.

-- --

c. Insufficient product in the

freezing cylinder.

c. Keep hopper full of mix. 9

4. Scored walls of freezing

cylinder.

a. Broken beater pins. a. Repair or replace beater

assembly.

-- --

b. Gear unit out of alignment. b. Contact a service

technician.

-- --

c. Bent beater assembly. c. Repair or replace. -- --

d. Missing front bearing. d. Replace or install front

bearing.

10

5. Unable to remove drive

shaft.

a. Lubrication on hex end of

drive shaft.

a. Do not lubricate the hex

end. Contact service

technician for removal.

10

b. Rounded corners of the

drive shaft, drive coupling

or both.

b. Replace drive shaft, drive

coupling or both.

-- --

6. Excessive mix leakage in

rear drip pan.

a. Improper or inadequate

lubrication on drive shaft

o--ring or seal on drive

shaft.

a. Use an approved food

grade lubricant (example:

Taylor Lube) and follow

lubrication procedures.

10

b. Bad or missing o--ring or

seal on drive shaft.

b. Replace rubber parts every

3 months.

19

c. Worn rear shell bearing. c. Contact a service

technician for replacement.

-- --