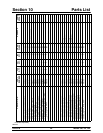

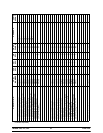

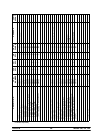

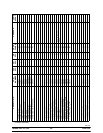

23

Models 340, 341, 342 T roubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY PAGE

REF.

4. The walls of the freezing

cylinder are scored.

a. Broken beater pins. a. Repair or replace the

beater assembly.

-- --

b. The gear unit is out of

alignment.

b. Contact service

technician.

-- --

c. The beater assembly is

bent.

c. Repair or replace the

beater assembly.

-- --

d. The front bearing is

missing.

d. Replace or install the front

bearing.

13

5. Unable to remove the

drive shaft.

a. There is lubrication on the

square end of the drive

shaft.

a. Do not lubricate the

square end. Contact

service technician for

removal.

10

b. The corners of the drive

shaft and/or drive coupling

are bent.

b. Replace the drive shaft

and/or drive coupling.

-- --

6. There is excessive mix

leakage in the rear drip

pan.

a. There is improper or

inadequate lubrication on

the drive shaft o-ring or

seal.

a. Use an approved food

grade lubricant (example:

Taylor Lube) and follow

the lubrication procedures.

10

b. Bad or missing o-ring or

seal on drive shaft.

b. Replace every 3 months. 10 / 25

c. The rear shell bearing is

worn.

c. Contact service technician

for replacement.

-- --

7. There i s no freezer

operation with the unit in

the “AUTO” position.

a. The unit is unplugged. a. Plug cord in wall

receptacle.

-- --

b. The beater motor has

tripped.

b. Place the power switch in

the “OFF” position. Allow

the motor to cool and then

resume normal operation.

Contact service technician

if the problem continues.

-- --

c. The circuit breaker is

tripped or the fuse is

blown.

c. Reset the circuit breaker

or replace the blown fuse.

-- --

8. The unit is not freezing

product when in the

“AUTO” position.

a. The torque rotor bound,

leaving the torque arm in

the “COLD” position.

Therefore, the compressor

will not run. (Far Right)

a. Free the torque rotor . -- --

b. The torque arm i s bent. b. Replace the torque arm. 13

c. The condensers are dirty. c. Clean the condensers

regularly.

20