Direct

Draw Beer Dispensers

Draft Beer

Problems

FIat Beer

a

Greasy

glasses.

o

Not enough

pressure.

.

Pressure shut off during

night.

a

Precooler

or coils too cold.

a

Loose tap or

vent

connection.

a

Sluggish

pressure

regulator.

a

Obstruction

in lines.

False Head

a

Pressure required does

not

correspond

to beer temperature.

o

Coils or direct

draw beer

lines

warmer

than

beer

in

keg.

a

Small

lines into

large faucet

shanks.

a

Beer drawn

improperly.

Wild

Beer

o

Beer

drawn

improperly.

a

Faucet

in

bad

or worn condition.

a

Klnks, dents, twists

or other

obstructions

in line.

a

Traps

in

beer

lines.

a

Beer

runs

are

too

long

or

lines are

not well-insulated.

o

Beer too

warm in kegs or lines.

o

Too

much

pressure.

o

CreepinEl

gauge

causing too

much

pressure.

Cloudy

Beer

o

Beer

over

chilled.

a

Beer in keg too

warm at sometime or

other.

a

Hot

spots

in beer

lines.

o

Cutting beer throuSh

faucet.

o

Beer line in

poor

condition.

a

Dirty

lines.

o

Beer that

has

been

frozen.

Bad Taste

a

Dirty

faucets.

a

Old or dirty

beer

lines.

a

Failure to

flush beer

lines with water

after

each empty

keg.

a

Unsanitary conditions

at bar.

a

Foul air or dirt

in lines.

.

Oily air;

greasy

kitchen air.

o

Temperature of

package

too

warm.

a

Dry

glasses.

Changing CO,Gas

Cylinder

Follow these

instructions

at

ALL

times

when

you

replace

a CO,

gas

cylinder:

1 f'lnco nrrlinrlor rf

"A"

2 Rcmovc lan

"f)"

from

barrel.

Pull

pressure

release ring

on

body of tap to

release

pressure

remaining in line.

(do

not

close

3.

Remove

or

loosen regulator

key

"8"

by turning counter

clockwise.

4. Remove regulator from

used

cylinder at

"E".

5. Remove dust cap

from new

gas

cylinder at

"E"

and clear

dust

from

outlet by

opening and

closinfl

valve

"A" quickly

using

appropriate wrench.

6. Attach regulator to new

cylinder al

"E".

(use

new fiber,/

plastic

washer, if required).

7. Open valve

"A"

all the

way.

8. Close valve

"C".

9. Adjust

regulator

key

"8"

by turning clockwise to set

pressure.

(check

setting by

opening

"C"

and

pulling

and

releasing

the

ring

"F"

on

the

nraccr rro rala2qo \/el\/o

On the

body of the tap)

10. Tap barrel at

"D"

with

valve

"C"

open.

NOTE

DON'T LAY CO2CYLINDERS FIAI,

DON',T DROP

CO,

CytTNDERS.

DON',T KEEP CO, CytTNDERS

IN COOLER.

lt requires 1,/2

pound

CO, to

dispense

t/2

barrel of

beer

at

38'F with 15

pounds

pressure

on Oarrel.

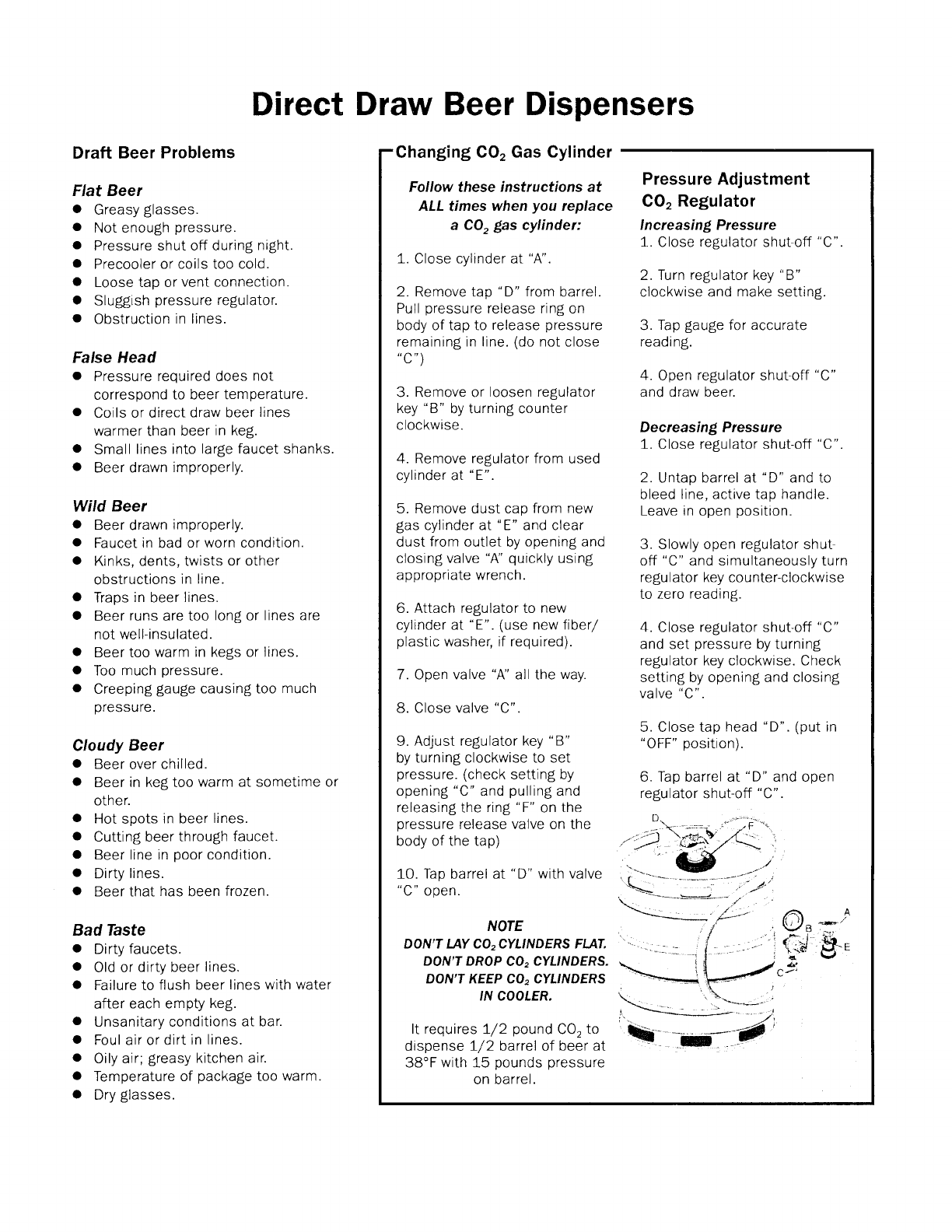

Pressure Adjustment

CO,

Regulator

lncreasin(, Pressure

1.

Close

regulator

shut off

"C".

2. furn

regulator

key

"

B"

clockwise and

make

setting.

3.

Tap

gauge

for accurate

reading.

4.

Open

regulator

shut-off

"C"

and draw beer.

Decreasing! Pressure

1. Close regulator shut-off

"C".

2.

Untap barrel at

"D"

and to

hlced linc antivc tan handle.

Leave in

open

position.

3. Slowly open

regulator

shut

off

"C"

and simultaneously turn

regu lator key

counter-clockwise

ti Tori rozdtnd

4. Close regulator shut-off

"C"

and set

pressure

by turning

regulator key clockwise. Check

setting by opening and closing

valve

"C".

5. Close tap

head

"D".

(put

in

"OFF"

positron).

6. Tap barrel at

"D"

and open

.^4,,t^+^. ^hi i+ ^#

"n4

rE6U rO

LUr Jr

rU L-U | |

V

,jt

\*b

,(

''--a

L;ij

//

t--_

C#

t

'*-

Q.2s

a .,,.

\r€l

s'