MODEL C24EA - WATER LEVEL CONTROL COMPONENTS

F25213 (May 2006) Page 22 of 52

WATER LEVEL CONTROL COMPONENTS

WATER LEVEL CONTROLS

Low Level Cut-Off & Differential Control

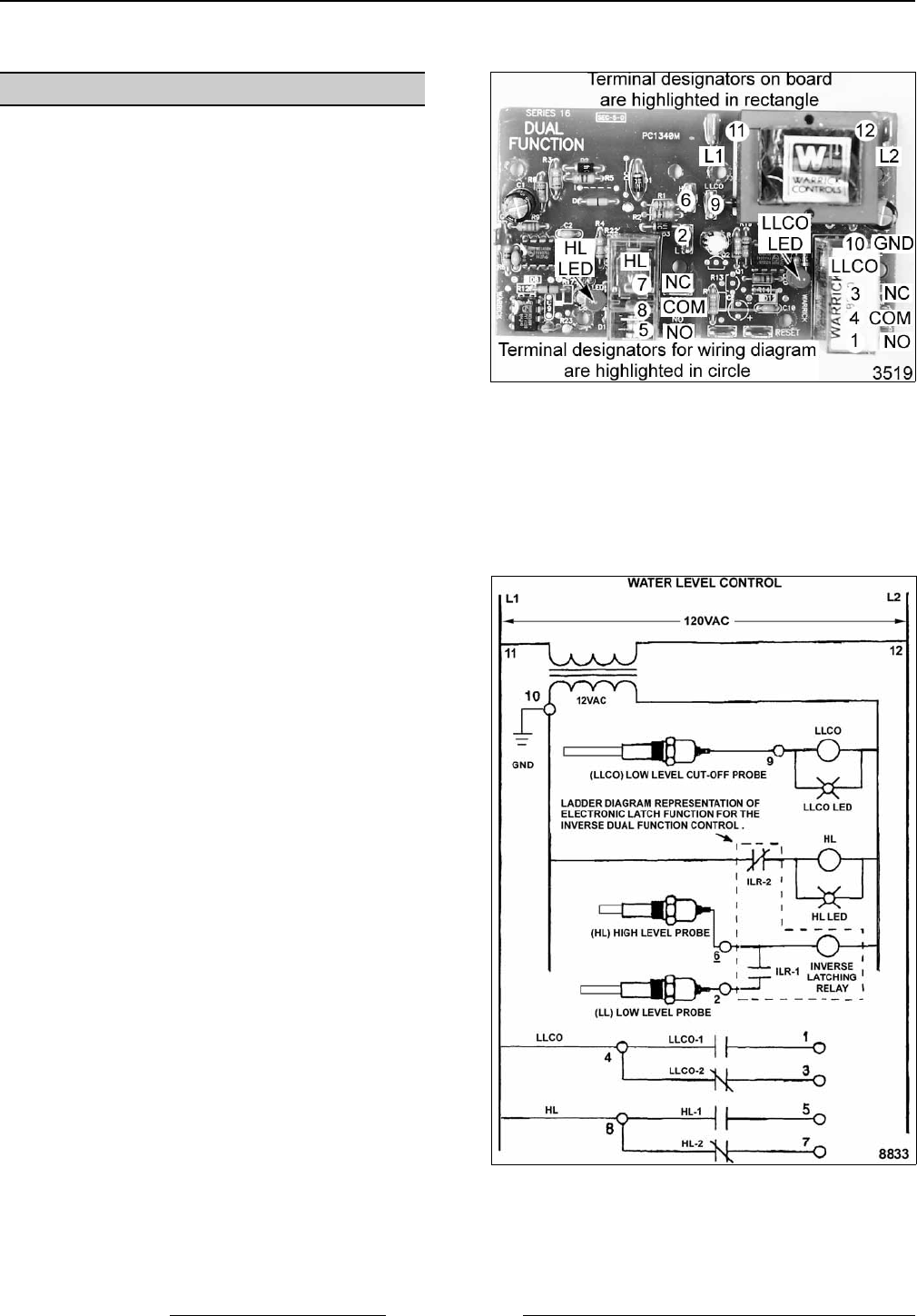

The steamer is equipped with three water level

sensing probes (high, low and low level cut-off) and

a water level control board. The water level control

board performs two functions: 1) Provide low level

cut-off protection to shut off the heat source in case

the water level drops below the low level cut-off

(LLCO) probe. 2) Perform as a differential level

control to maintain the water level between the low

and high water level probes.

The water level control (WLC) board has input

voltage (120VAC) across terminals 11 and 12 which

powers the primary side of the transformer. On one

side of the transformer secondary, power is provided

to the control by a series path through chassis

ground (terminal 10). The other side of the

transformer secondary (12VAC) is attached to the

probe that directs power to the other side of WLC

board relay coils (LLCO and HL) and to the inverse

latching relay (ILR) electronic circuit on the WLC

board. As water enters the generator, it becomes

part of the WLC board circuit. When the water level

in the generator reaches a probe, that circuit is

completed.

The inverse latching relay of the WLC board is de-

energized, leaving the ILR-1 (N.O.) and ILR-2 (N.C.)

contacts in their shelf state.

When the main power switch is turned on, power is

supplied to the WLC board which energizes the high

level (HL) relay, closes HL-1 normally open contacts,

and illuminates the HL relay LED. With the HL-1

contacts closed, the slow fill solenoid is energized

and water begins filling the generator.

When the water level reaches the low level cut-off

(LLCO) probe, the LLCO relay is energized and

illuminates the LLCO LED. With the LLCO-1 contacts

closed, the heat source can be energized provided

the auxiliary control(s) in the heating circuit are

satisfied. The LLCO relay will remain energized and

its LED will stay lit until the water level in the

generator drops below the LLCO probe.

When the water level reaches the low level (LL)

probe, power to terminal 2 on the WLC board is

present but no switching occurs.

After the water level reaches the high level (HL)

probe, the inverse latching relay of the WLC board is

energized and locked through the low level probe

(LL) and ILR-1 contacts. With ILR-2 contacts open,

HL relay is de-energized and the HL LED goes out.

With the HL-1 contacts open, the slow fill solenoid is

de-energized, stopping the flow of water into the

generator.

When the water level drops below the low level (LL)

probe, power is removed from the inverse latching

relay, the HL relay energizes through ILR-2 and HL

contacts change state. The slow fill solenoid is

energized through HL-1 to refill the generator and

the HL LED is lit. The HL relay and LED will toggle

on and off during a cooking cycle as needed.