MODEL C24EA - GENERAL

F25213 (May 2006) Page 4 of 52

SPECIFICATIONS

NOTE: All C24EA steamers, with exception of 480V steamers, are shipped pre-wired for 208/60/3 operation.

Steamer heating element wiring connection change is required if connecting to 208/60/1, 240/60/1 or 240/60/3

electrical service.

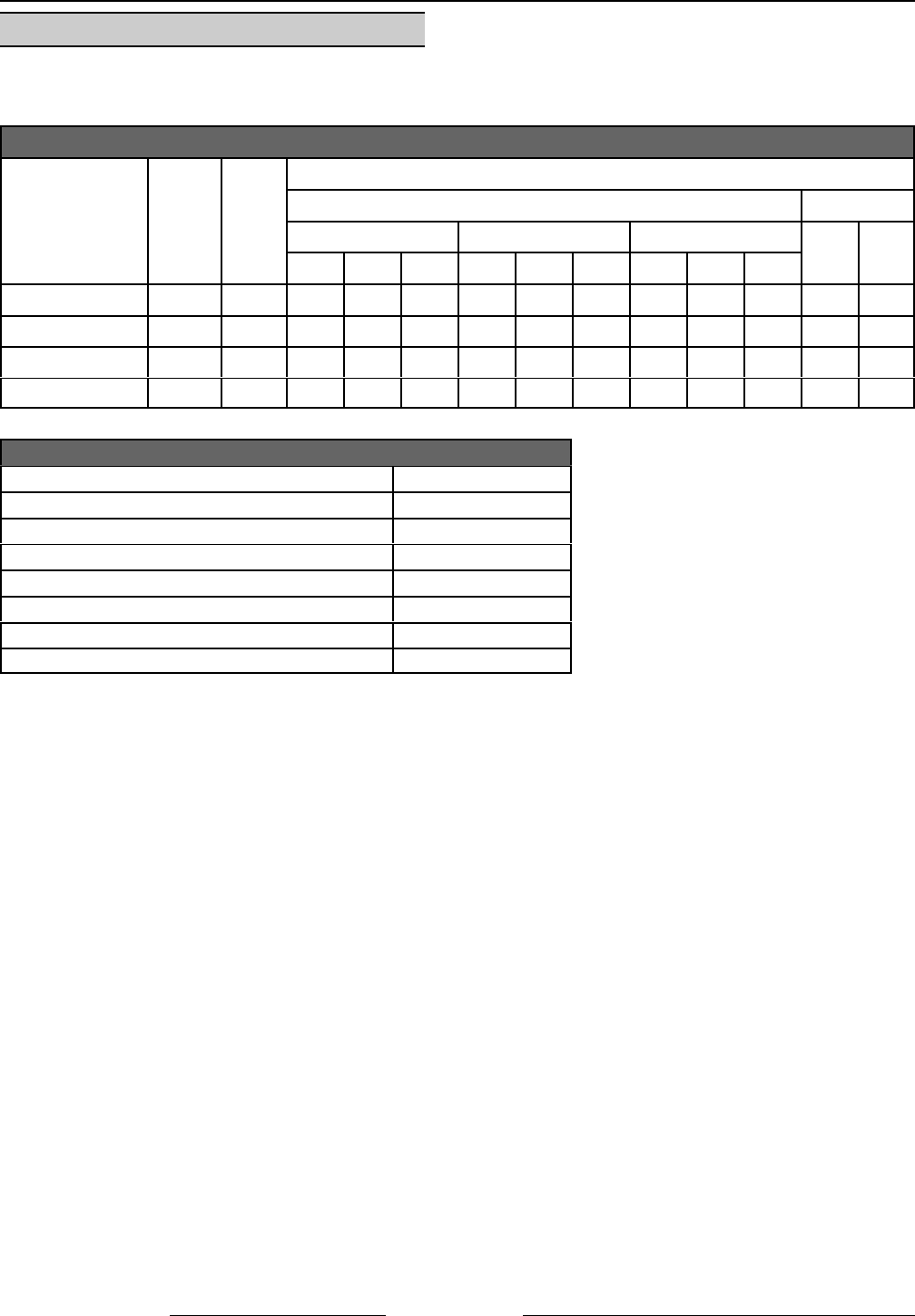

ELECTRICAL SPECIFICATIONS

MODEL

TOTAL

kW

Hz.

AMPERAGE

3 PHASE 1 PHASE

208V 240V 480V

208V 240V

L1 L2 L3 L1 L2 L3 L1 L2 L3

C24EA3 - Basic 8.5 50/60 26.5 26.5 17.7 20.5 20.5 20.5 10.3 10.3 10.3 40.9 35.4

C24EA5 - Basic 15.0 50/60 46.8 46.8 31.2 36.1 36.1 36.1 18.0 18.0 18.0 72.1 62.5

C24EA3 - Pro 9.25 50/60 26.5 28.9 20.0 20.5 23.2 23.2 10.2 11.6 11.6 43.6 38.5

C24EA5 - Pro 15.75 50/60 46.8 49.2 33.6 36.1 38.8 38.8 18.0 19.4 19.4 74.8 65.6

WATER SUPPLY REQUIREMENTS

! Supply pressure should be ........................ 20-60 psig

! In line strainer for supply line (Supplied)

! Total dissolved solids (TDS)* .................... less than 60 ppm

! Total alkalinity ........................................... less than 20 ppm

! Silica ......................................................... less than 13 ppm

! Chloride .................................................... less than 4.0 ppm

! PH factor ................................................... 6.5 to 8

! Undissolved Solids..................................... less than 5 microns

*17.1 ppm = 1 grain of hardness

Water hardness below 4 grains/gal requires water treatment to reduce

potential corrosion. Hardness above 6 grains/gal should be treated by

water conditioner, water softener or in-line treatment.

Water Conditioning

It is recommended that a local water treatment specialist be consulted before the installation of any steam

generating equipment.

Furnishing the steam generator with properly conditioned water to reduce scale formation is important. Scale

formation will reduce steam output, cause premature component failure and shorten equipment life. Most water

supplies contain scale producing minerals such as calcium and magnesium. As steam is generated, the minerals

remain and dissolve into the remaining water. As the concentration of these minerals increases past a certain

point, they precipitate from the water and coat the inside of the tank, heating elements, thermostat bulbs and water

level probes. Because of the high temperature of these surfaces, the precipitated minerals bake onto them and

become very difficult to remove.

This phenomenon causes several problems:

1. Reduces the heat transfer efficiency of the heaters.

2. Causes premature failure of the heaters.

3. Water level probes will give false readings.

4. Thermostat bulbs will sense temperature incorrectly.

These problems are common to any manufacturer's steamer regardless of design, but they can all be prevented

by furnishing the steam generator tank with properly conditioned water. Vulcan recommends the water contain

less than 60ppm of total dissolved solids (TDS) and have a PH factor between 6.5 to 8.