— 6 —

When test pressures are

1

/2 psig (3.45 kPa) or less, the cooker must be isolated from the gas supply

piping system by closing its individual shutoff valve.

ELECTRICAL CONNECTIONS

Make supply connections using insulated copper wire suitable for at least 90°C for the rated load.

When initially selecting conduit size, keep in mind the possibility of additional platens being added to

the duplex cooker at a later date.

The electrical diagram is attached to the hinged control panel cover.

Permanently Connected Duplex Cookers

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

Cord Connected Duplex Cookers

WARNING: THE SUPPLY CORD ON THE GAS DUPLEX COOKER IS PROVIDED WITH A THREE-

PRONG GROUNDING PLUG. IT IS IMPERATIVE THAT THIS PLUG BE CONNECTED INTO A

PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE RECEPTACLE IS NOT THE

PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT REMOVE THE GROUNDING

PRONG FROM THIS PLUG.

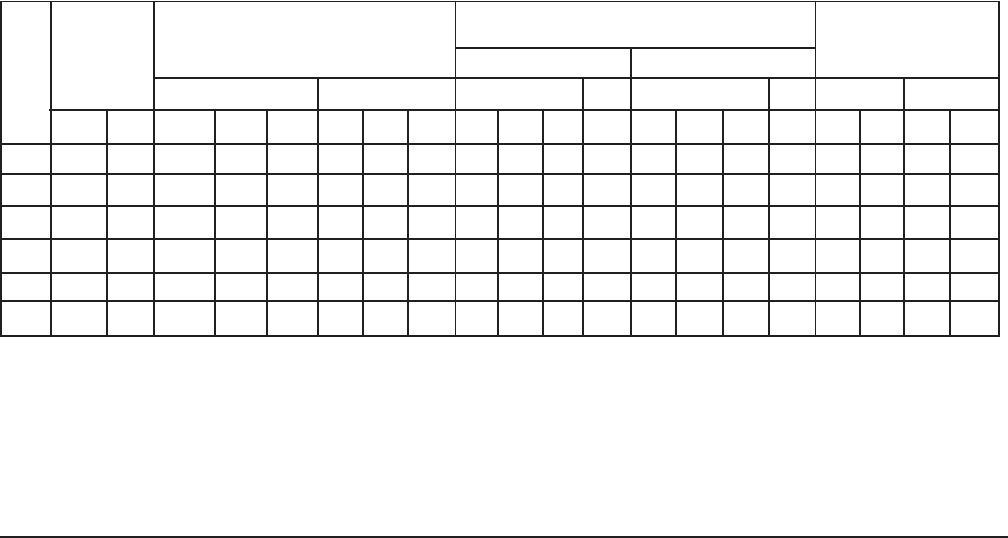

ELECTRICAL DATA

Total Total Loading KW Nominal Amps./Line Circuit

Platens

KW Per Phase 240V 208V Size *

Per Conn. 240V 3 Ph. 208V 3 Ph. 3 Ph. 1 Ph. 3 Ph. 1 Ph. 240V 208V

GDC 240V 208V L1-L3 L2-L3 L1-L3 L1-L2 L2-L3 L1-L3 L1 L2 L3 L1-L3 L1 L2 L3 L1-L3 3Ph. 1Ph. 3Ph. 1Ph.

1 2.67 2 2.67 0 0 2 0 0 10 10 0 11 9 9 0 10 15 15 15 15

2 5.34 4 2.67 2.67 0 2 2 0 10 20 10 26 9 17 9 19 25 35 25 25

3 8.01 6 2.67 2.67 2.67 2 2 2 20 20 20 34 17 17 17 29 25 45 25 40

4 10.68 8 2.67 2.67 5.34 2 2 4 29 20 29 45 25 17 25 39 40 60 35 50

5 13.35 10 5.34 2.67 5.34 4 2 4 39 20 39 56 34 17 34 48 50 70 45 60

6 16.02 12 5.34 5.34 5.34 4 4 4 39 39 39 67 34 34 34 58 50 90 45 80

* MINIMUM CIRCUIT AMPACITY AND MAXIMUM CIRCUIT BREAKER SIZE (AMPS.) compiled in

accordance with The National Electrical Code (latest edition).