— 9 —

DIRECT STEAM KETTLES

Maximum Flow Rate of Dry Steam in Pounds per Hour

Supply

Pressure

Standard Pipe Size

1

/2"

3

/4"1"1

1

/4"1

1

/2"2"

5 PSIG 20 40 70 140 210 380

10 PSIG 30 60 110 220 320 600

15 PSIG 40 80 150 290 430 n/a

20 PSIG 50 100 180 360 530 n/a

25 PSIG 60 120 220 430 n/a n/a

30 PSIG 70 140 250 500 n/a n/a

35 PSIG 80 160 290 570 n/a n/a

50 PSIG 100 210 380 760 n/a n/a

Chart values are based on 100' of clean iron pipe. Steam losses due to elbows, reductions, heat loss

or condensing steam were not considered.

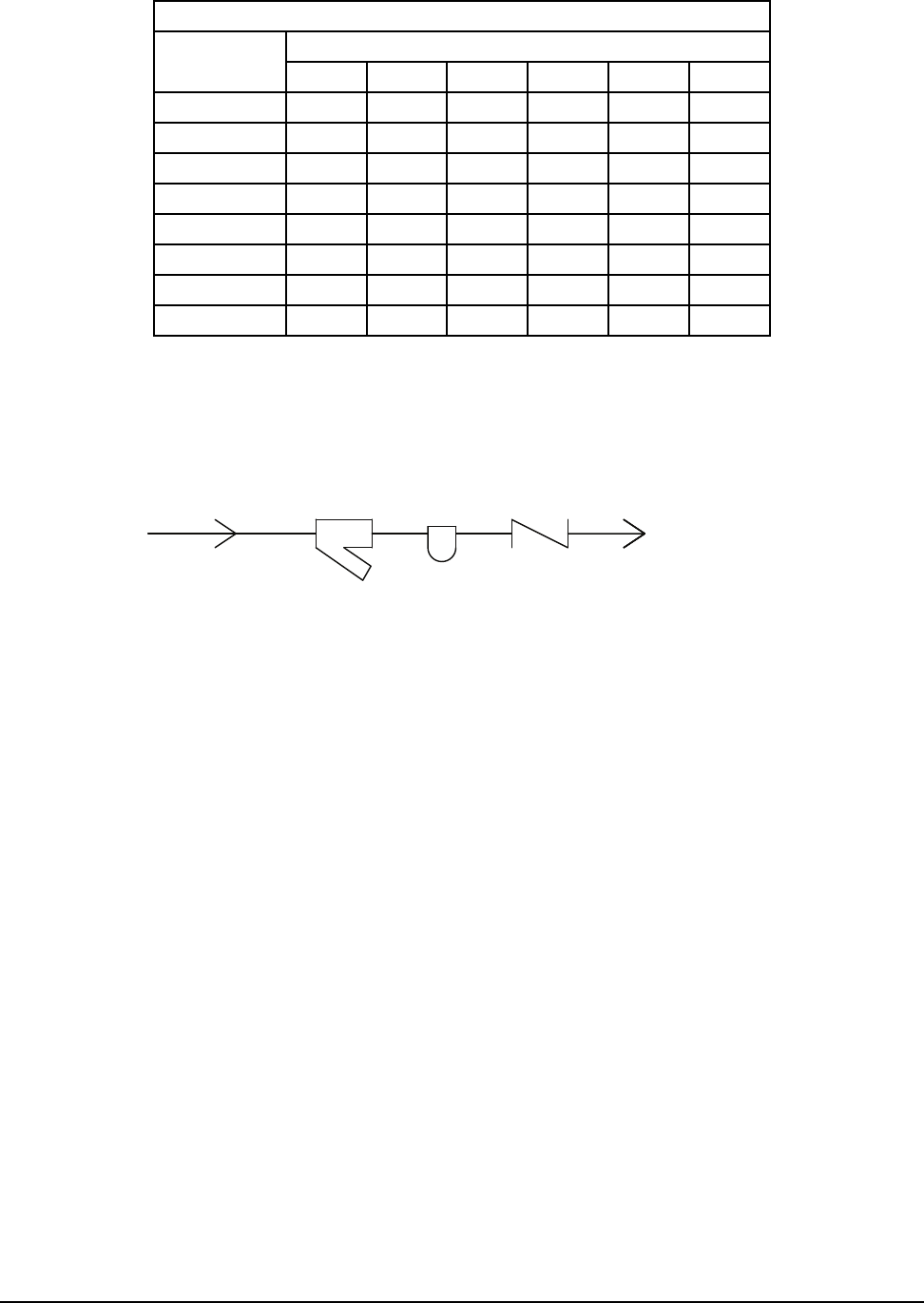

Connect the kettle condensate return line (Fig. 2) to an open drain or to a boiler condensate return

line. Boiler condensate return lines must have a check valve (not supplied).

Fig. 2

INITIAL START-UP

• Pour a small amount of water into the kettle.

• Open the steam inlet valve.

• When the water begins to boil, inspect all of the fi ttings to ensure that there are no leaks.

• Check the safety valve by pulling the ring far enough to allow steam to escape. Let the valve

snap back into place to reseat the valve so it will not leak.

• Shut down the unit by closing the steam inlet valve.

• Open the draw-off valve to ensure that it functions from fully opened to fully closed position. If

it functions properly, then the kettle is ready for use.

STRAINER

FROM KETTLE

TO DRAIN OR BOILER

CONDENSATE RETURN

CHECK

VALVE

STEAM

TRAP