GAS KETTLES

— 6 —

GAS CONNECTIONS

Gas supply connections and any pipe joint compound must be resistant to the action of

propane gases.

Codes require that a gas shutoff valve be installed in the gas line ahead of the kettle.

Connect the gas supply line to the gas valve on the kettle. Make sure the pipes are clean and free of

obstructions, dirt and piping compound.

The gas line must be capable of delivering gas to the kettle without excessive pressure drop at the rate

specified on the nameplate. Suggested gas supply line pressure is 7" Water Column (1.75 kPa) for

natural gas and 11" Water Column (2.75 kPa) for propane. Burner manifold pressure is (-)1.4" Water

Column (0.350kPa) for natural gas and (-)1.4" Water Column (0.350 kPa) for propane.

The proper sizing and installation of the gas connection is important for the machine to operate within

its design specifications. In some installations, the gas supply may not be sufficient enough to allow

all the gas equipment to operate properly at peak loads; or when other equipment with a high BTU/

hr. input requirement is operating. The connection to the machine becomes even more important in

this type of location. Flexible gas connectors with quick disconnect or swivel fittings (when used) and

gas connectors beyond the length necessary will reduce the BTU/hr. flow capacity to the machine.

NOTE: Do not use corrugated stainless steel tubing

for

commercial gas equipment supply connections.

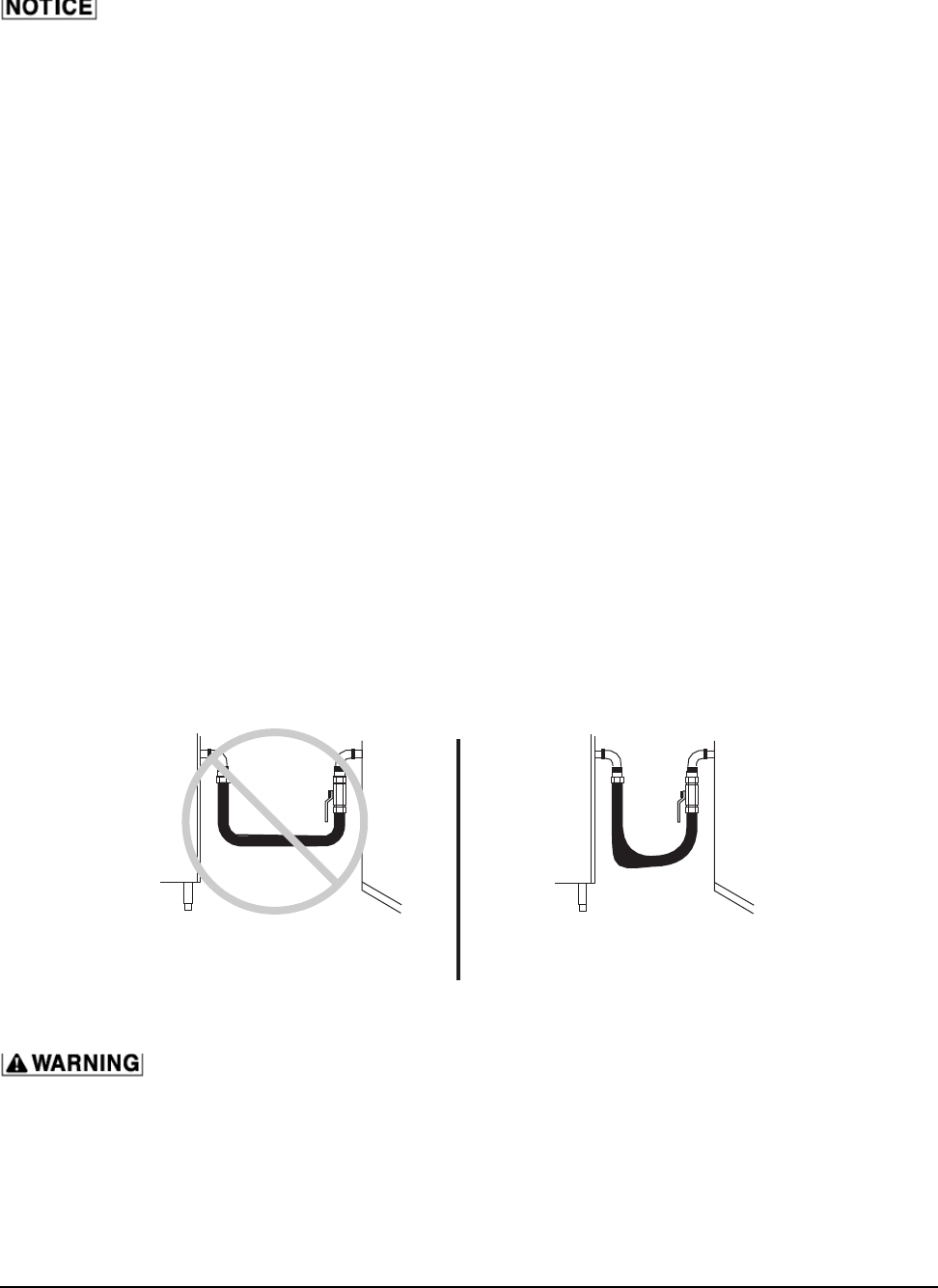

NOTE: A straight gas connection is the ideal condition for the rated BTU/hr. flow capacity of the

connector. If a straight connection is not possible and a flexible gas connector is used, do not twist,

kink or excessively flex the connector beyond a U shape. Flexing the gas connector as described will

restrict gas flow or may damage the connector.

Changing a flexible gas connector may raise the BTU/hr. flow capacity enough to allow the machine

to

operate within its design specifications.

(i.e.

Removing the quick disconnect

fitting, installing a

shorter

gas connector or installing a larger diameter gas connector.) An alternative may be to move the

equipment to a different gas supply location in the kitchen. (i.e. Closer to the main supply into the

kitchen or away from other equipment with high BTU/hr. input requirements.)

KETTLE WALL KETTLE WALL

INCORRECT INSTALLATION CORRECT INSTALLATION

Prior to lighting, check all joints in the gas supply line for leaks. Use soap and

water

solution.

Do not use an open flame.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.