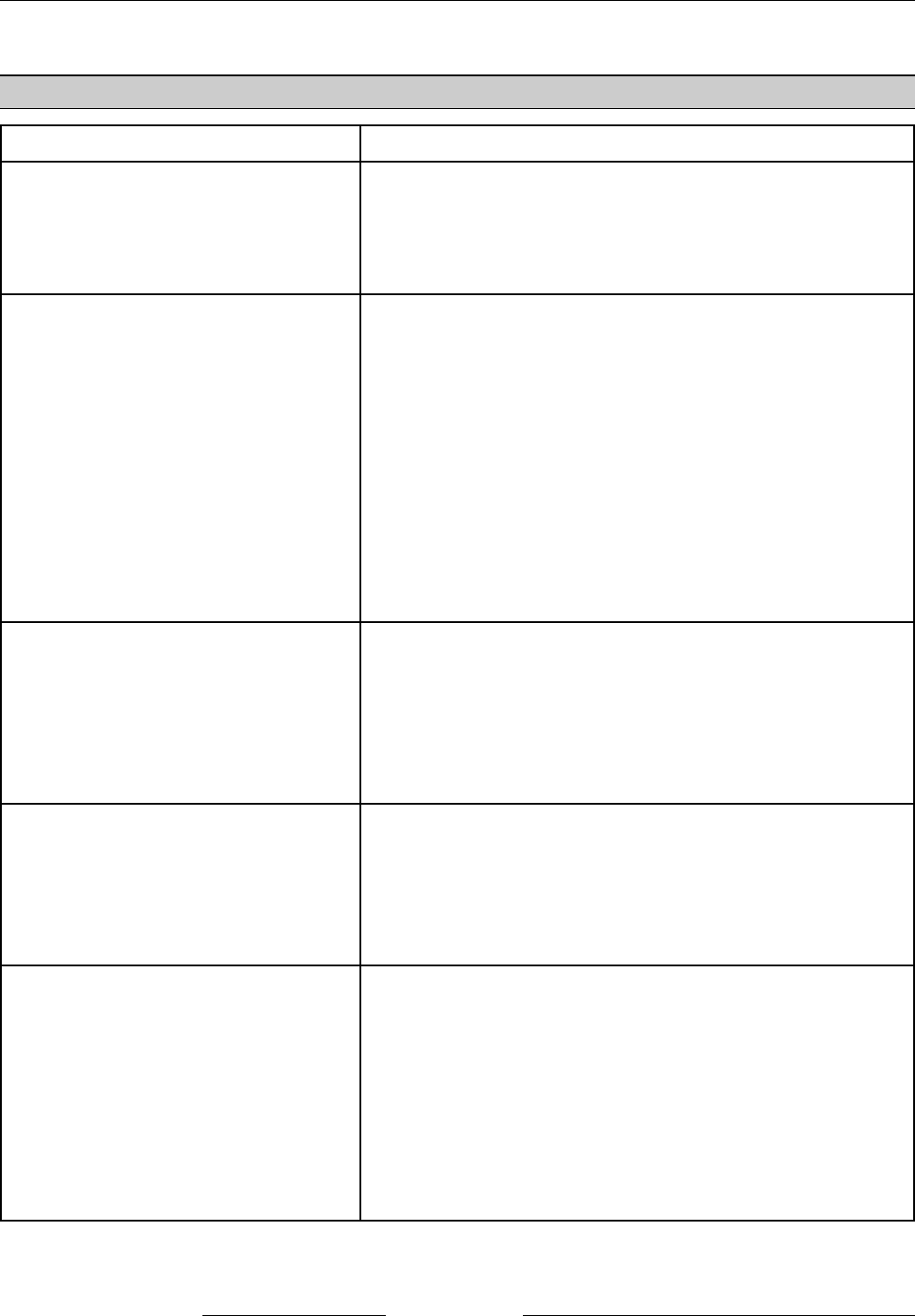

VHX SERIES STEAMER - TROUBLESHOOTING

F25154 (February 2004) Page 42 of 48

TROUBLESHOOTING

BOILER BASE CONTROLS

SYMPTOM POSSIBLE CAUSES

Steamer does not operate, low water light

and high pressure lights not lit.

1. Main circuit breaker off; or control circuit fuse F1 or F2 open.

2. Supply voltage incorrect.

3. Supply voltage transformer - jumper missing or incorrect

location; or transformer inoperative.

4. Power switch malfunction.

Steamer on, cannot reset low water

condition. Low water light lit, ready light

not lit, water level not visible in sight glass.

1. Boiler fill water off or filtering system clogged.

2. Boiler blowdown/drain valve stuck open or malfunction.

3. Manual blowdown valve open on water level probe housing.

4. Lime scale build-up on water level probes.

5. Water level control board - ground connection open, not

receiving power or malfunction.

6. Boiler fill valve clogged or malfunction.

7. Auxiliary water level control board - ground connection open,

not receiving power or malfunction.

8. Reset switch malfunction.

9. K1, K3 relays not seated properly or malfunction.

10. Water too pure for probes to properly conduct electricity.

11. Interconnecting wiring malfunction.

Steamer on, cannot reset low water

condition. Low water light lit, ready light

not lit, water level visible in sight glass.

1. Ground connection open on auxiliary water level control board.

2. Lime scale build-up dried on AUX LLCO probe.

3. Auxiliary water level control board not receiving power or

malfunction.

4. Reset switch malfunction.

5. K1, K3 relays not seated properly or malfunction.

6. Interconnecting wiring malfunction.

Steamer on, cannot reset high pressure

condition. High pressure light lit, pressure

gauge indicating 15PSI.

1. Cycling pressure switch out of adjustment or malfunction.

2. High limit pressure switch out of adjustment or malfunction.

3. Reset switch malfunction.

4. K2, K4 relays not seated properly or malfunction.

5. Steam trap malfunction.

6. Interconnecting wiring malfunction.

Boiler operates but pressures are below

the normal cycling range of 10-12 PSI.

1. Manual blowdown valve on water level probe housing open.

2. Boiler blowdown valve clogged and not fully closing.

3. Supply voltage incorrect.

4. Cycling pressure switch out of adjustment or malfunction.

5. Heating elements not wired correctly.

6. Contactor(s) malfunction.

7. Heating element malfunction.

8. Steam trap malfunction.

9. Excessive load on boiler due to other equipment connected to

steam line (outlet from boiler).