VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

F25154 (February 2004) Page 22 of 48

HEATING ELEMENT TEST

VOLTAGE

KW PER

ELEMENT

AMPS PER

ELEMENT

OHMS PER

ELEMENT

208 9.0 14.4 14.4

240 9.0 12.5 19.2

480 9.0 6.3 76.8

208 10.5 16.9 12.4

208 12.0 19.3 10.8

240 12.0 16.7 14.4

480 12.0 8.3 57.6

NOTES:

1. Values in the table are nominal.

Tolerance is +5/-10%.

2. Voltage values are @ 60HZ.

3. Resistance values (ohms) are @ room

temperature. If heating elements are

above room temperature, the measured

resistance will be greater.

4. Each heating element has 3 separate

internal elements.

1. Access the heating elements as outlined in

REMOVAL AND REPLACEMENT OF PARTS.

2. Measure voltage at heating element terminals

and verify it against data plate voltage.

A. If voltage is incorrect, see

TROUBLESHOOTING.

B. If voltage is correct, continue with

procedure.

3. Check current draw (amps) through the heating

element lead wires.

NOTE: Checking current draw is the preferred

method over a resistance check when a clamp on

type amp meter is available.

A. If current draw is correct then heating

element is functioning properly. See table

for proper values.

B. If current draw is not correct, turn power

switch off and disconnect the electrical

supply.

1) Install a replacement heating element.

C. If unable to check current draw, a

resistance check may indicate a

malfunctioning element.

1) Turn power switch off and disconnect

power to machine.

2) Remove lead wires from heating

element and check resistance (ohms).

See table for proper values.

4. Check for proper operation.

COOKING COMPARTMENT

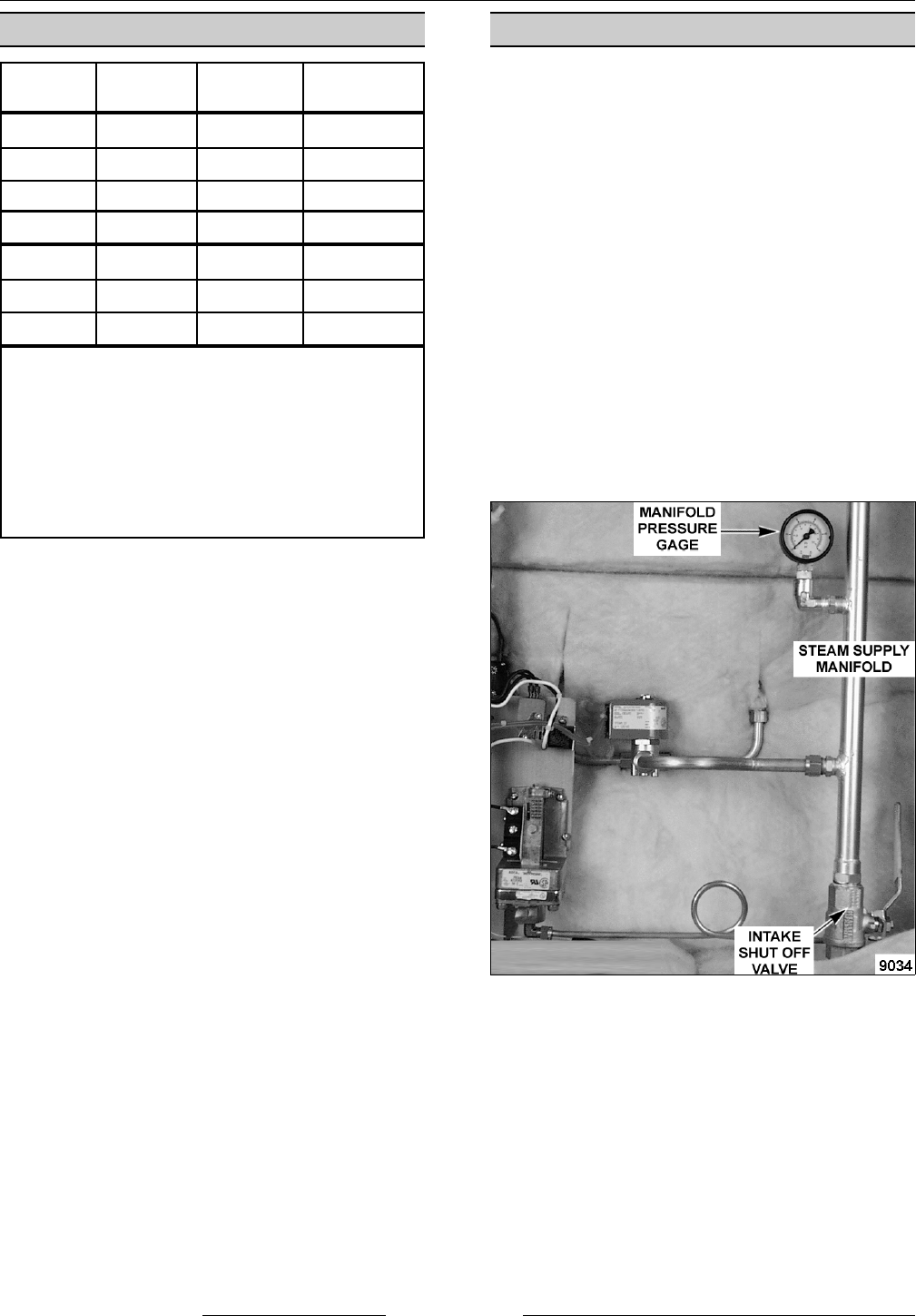

NOTE: Before proceeding with intake shut-off valve

adjustment, monitor boiler pressure gauge and verify

boiler is operating between 10-12 PSI. If boiler

pressure adjustment is necessary, refer to CYCLING

PRESSURE SWITCH ADJUSTMENT.

Intake Shut-Off Valve Adjustment (Steam Flow)

1. Remove right side compartment panel.

2. Allow boiler to fully pressurize (heat turns off).

NOTE: The intake shut-off valve adjustment should

be made while boiler pressure is at the upper cycling

limit.

3. Turn both cooking compartment timers on.

4. Open the intake shut-off valve completely.

5. Slowly begin to close the intake shut-off valve

and monitor manifold pressure gauge. Adjust

the valve until manifold pressure gauge reading

is between 8-10 PSI.

6. Monitor manifold pressure gauge reading for

two complete boiler cycles.

A. If the manifold pressure gauge reading

stays within tolerance while the boiler is

cycling, the intake shut-off valve is set

correctly.

B. If the manifold pressure gauge reading is

outside of the tolerance repeat the

adjustment.

7. Once the steam supply manifold pressure is set

correctly, turn both cooking timers off and install

right side compartment panel.