VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

F25154 (February 2004)Page 21 of 48

3. To check boiler fill valve:

A. Verify 120VAC to solenoid valve coil.

B. If voltage is correct but valve is not opening

(little or no water flow), turn power switch

off and disconnect power to machine.

1) Remove lead wires from coil and

check for continuity.

2) If no continuity is measured, install a

replacement solenoid valve and check

for proper operation.

3) If continuity is measured, the coil is

good.

C. If voltage is not correct, check main water

level control board as outlined under

WATER LEVEL CONTROLS TEST.

4. To check cold water condenser valve:

NOTE: Valve should energize only during cooking

cycles and at boiler blowdown/drain.

A. Verify 120VAC to solenoid valve coil.

B. If voltage is correct but valve is not opening

(little or no water flow), turn power switch

off and disconnect power to machine.

1) Remove lead wires from coil and

check for continuity.

2) If no continuity is measured, install a

replacement solenoid valve and check

for proper operation.

3) If continuity is measured, the coil is

good. Continue with procedure for

additional valve checks.

C. If voltage is not correct, check cold water

condenser thermostat as outlined under

COLD WATER CONDENSER

THERMOSTAT ADJUSTMENT.

5. To check valve ports for clogs or valve

component malfunction, continue with

procedure for disassembly and inspection of

internal components.

6. Turn water supply off, disconnect water line

from valve body then remove solenoid valve.

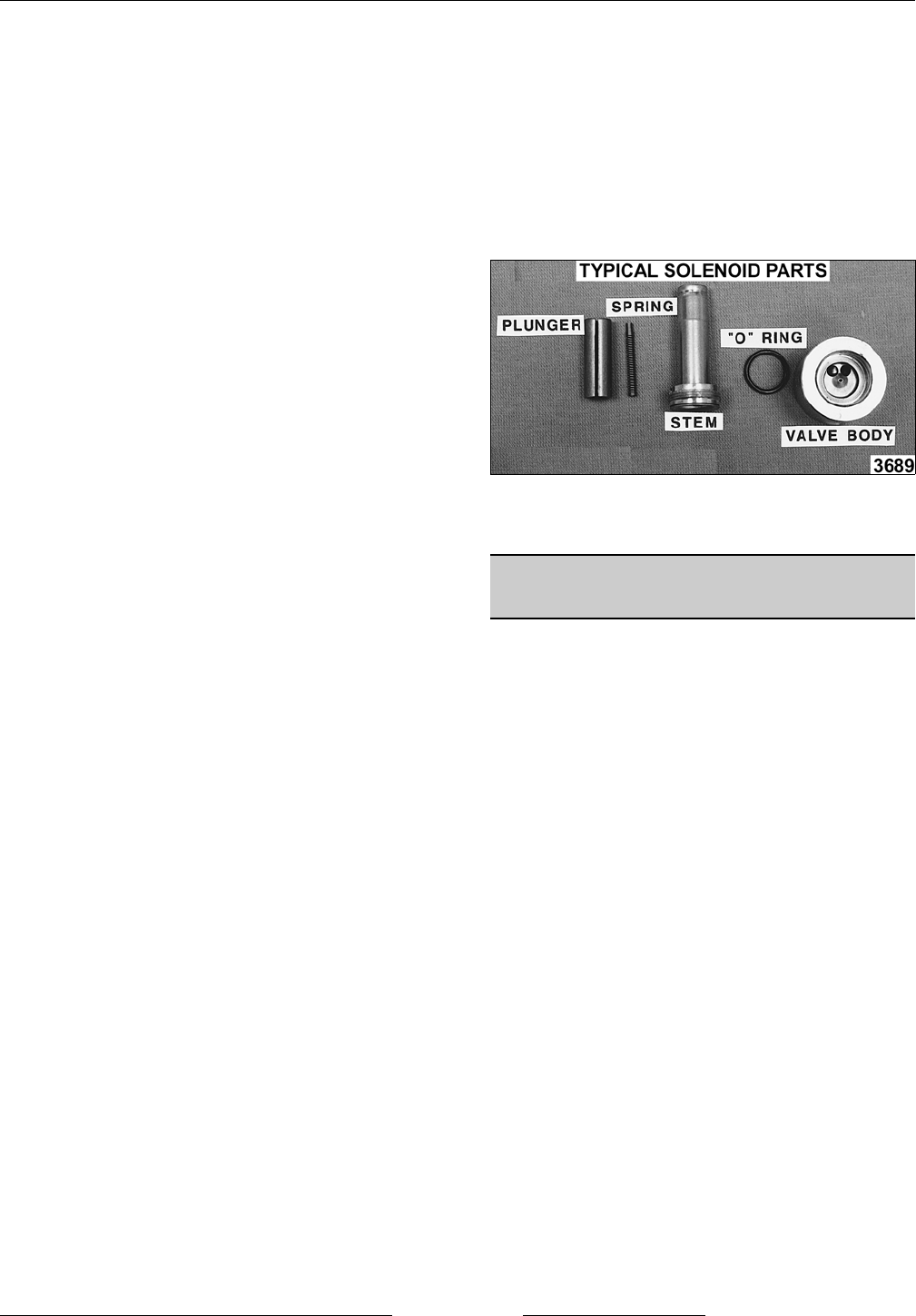

7. Remove coil assembly from valve stem

8. Secure the valve body to keep it from turning.

9. Scribe a line on stem nut to valve body for

proper re-tightening then remove stem locking

nut and remove the stem from valve body.

10. All parts are now accessible for inspection and

cleaning.

NOTE: If internal solenoid parts appear to be

damaged or worn, then replace the solenoid valve.

Do not reuse damaged or worn parts. No internal

solenoid parts are available as a service

replacement.

A. Check rubber seal on bottom of plunger.

B. Check plunger spring.

C. Check O-ring in valve body.

D. Check ports in valve body.

11. Reverse procedure to install and check for

proper operation.

COLD WATER CONDENSER

THERMOSTAT ADJUSTMENT

During a cooking

cycle or boiler blowdown/drain, the

cold water condenser thermostat (N.O.) should

close and energize the cold water condenser

solenoid valve. The water from spray nozzle mixes

with the drain water in the condenser drain box to

reduce drain water temperature and condense

steam vapors.

If excessive steam vapors are seen exiting the drain,

adjust the cold water condenser thermostat as

outlined below.

1. Turn power switch off and allow boiler to

blowdown/drain.

2. Access cold water condenser

thermostat as

outlined under PRESSURE SWITCH

CONTROL BOX COMPONENTS in REMOVAL

AND REPLACEMENT OF PARTS.

3. Turn thermostat shaft fully counterclockwise to

energize the cold water condenser solenoid

valve.

A. Allow cold water to flow until condenser

drain box has completely cooled.

B. Slowly turn thermostat shaft clockwise until

thermostat opens and de-energizes the

solenoid valve. Turn shaft an additional 1/4

turn to prevent the thermostat from closing

near room ambient temperatures.

4. Check for proper operation.