VHX SERIES STEAMER - ELECTRICAL OPERATION

F24700 (October 2001) Page 48 of 68

upper and lower set point limits. The

cycling pressure switch continues to

energize and de-energize the heating

circuit to cycle the burner ON and OFF.

This sequence continues until one of the

following occurs:

1) Power switch is turned OFF.

2) Boiler water level drops below the

LLCO probes for the main water level

control (WLC) and the auxiliary low

level control.

3) Boiler pressurizes to 15 PSI, causing

the high limit pressure switch to open.

Water Refill (After Initial Fill)

1. Water level drops below low level probe (LL).

A. HL relay is energized.

1) HL-3 (N.O.) contacts close.

2) Fill solenoid is energized.

3) HL LED comes ON.

2. Water reaches LL (low level) probe.

3. Water reaches high level probe.

A. HL relay is de-energized.

1) HL-3 (N.O.) contacts open.

2) Fill solenoid is de-energized.

3) HL LED goes out.

4. The water refill cycle will occur whenever the

water level is below the low level probe and will

not affect the operation of either the preheat or

cook cycle.

Boiler Blowdown/drain

1. Power switch turned OFF.

A. Automatic blowdown solenoid valve (N.O.)

is de-energized and valve opens to drain

the boiler.

B. Power is removed from all components

except cold water condenser (CWC)

thermostat and solenoid valve. The CWC

thermostat cycles as necessary to lower

the discharge temperature of the water

and condense steam going into the drain.

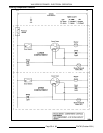

OLD STYLE CONTROLS - BOILER

This sequence of operation is written for boiler

bases with the old style boiler controls. See

"BOILER CONTROL STYLES" under "GENERAL".

Refer to schematic diagram 5480.

Initial Fill And Preheat

1. Conditions.

A. Power switch OFF.

B. Boiler connected to correct voltage

(120VAC).

1) Power to cooking compartment

controls. See "COOKING

COMPARTMENT CONTROLS" later

in this section.

C. Boiler properly grounded (boiler and water

level controls share a common ground)

D. Gas and water supply valve(s) ON.

E. Main gas valve ON.

F. Cycling pressure switch CLOSED.

G. High limit pressure switch CLOSED.

H. Cold water condenser (CWC) thermostat

OPEN.

I. Automatic blowdown valve (A.B.D.) OPEN

and boiler empty.

2. Turn power switch ON.

A. Relay R4 energized and R4 contacts

(N.O.) CLOSE.

B. Power ON light (red) comes ON.

C. Blowdown solenoid valve is energized and

CLOSES.

D. Auxiliary water level control is powered.

1) Aux. LLCO N.O. contacts remain

OPEN (Aux. LLCO relay de-

energized).

E. Low water level light (amber) comes ON.

NOTE:

The low water indicator light will remain

ON and the safety circuit de-energized until the

water level in the boiler reaches the auxiliary

low level cut-off probes (aux. LLCO, minimum

level) for the aux. water level control, and the

manual reset switch is pressed.

F. High pressure light (amber) comes ON.

NOTE:

The high pressure indicator light will

remain ON and the safety circuit de-energized

until the manual reset button is pressed (high

limit pressure switch must be closed).

G. Power is connected through the high limit

pressure switch contacts (N.C.) to one side

of the push button reset switch.

H. Water level control is powered (Low Level

Cut-off & Differential Control).

1) High level (HL) relay is energized, HL

contacts (N.O.) CLOSE

a. HL LED lights up.

b. Fill solenoid is energized and

water begins filling boiler (fill

time 4-11 min.).